“I am 100% satisfied with our investment, because it’s exactly what we needed: while on average we produced a batch of 40/50 conditioners in 20 days, today we produce a batch of 200 parts in 10 days.”

Fabio Pollastri - Co-Owner of Metalsystem

Increase speeds by 300%

Does the work of 3 Press Brakes!

The Salvagnini panel bender is an advanced sheet metal bending machine that streamlines the entire bending process. Designed for productivity, efficiency, and flexibility, it adapts to different batch sizes and material thicknesses, ensuring high-quality, repeatable results with minimal manual intervention.

Choose Your Panel Bender

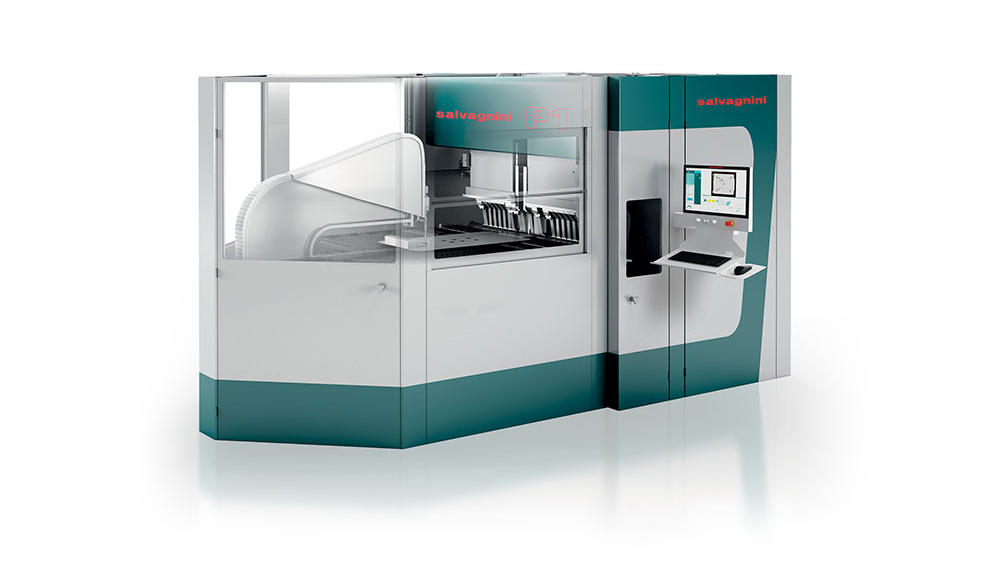

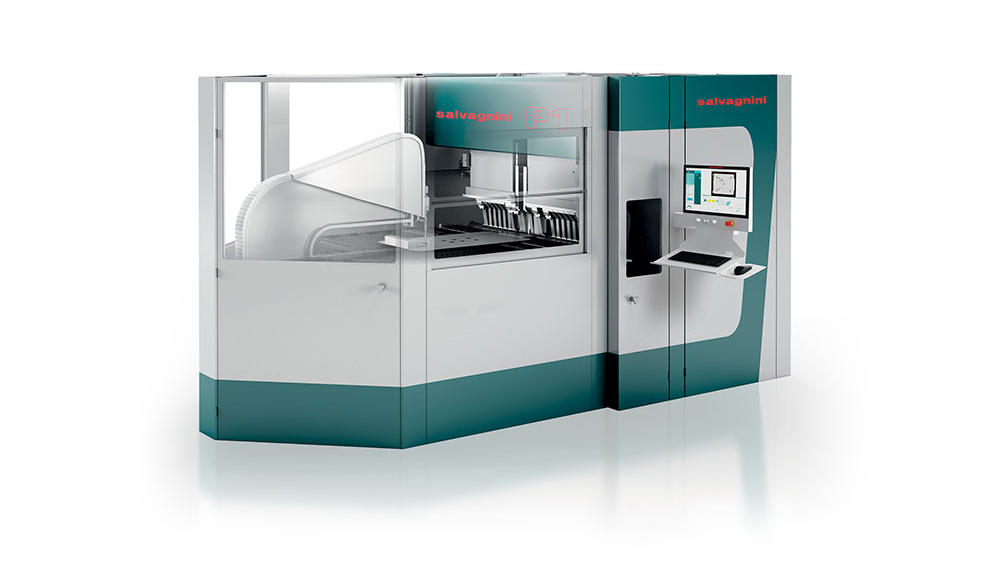

Compact & Optimized

The P1 is our entry level panel bender, With its automatic bending and handling cycles, it offers unparalleled productivity and flexibility.

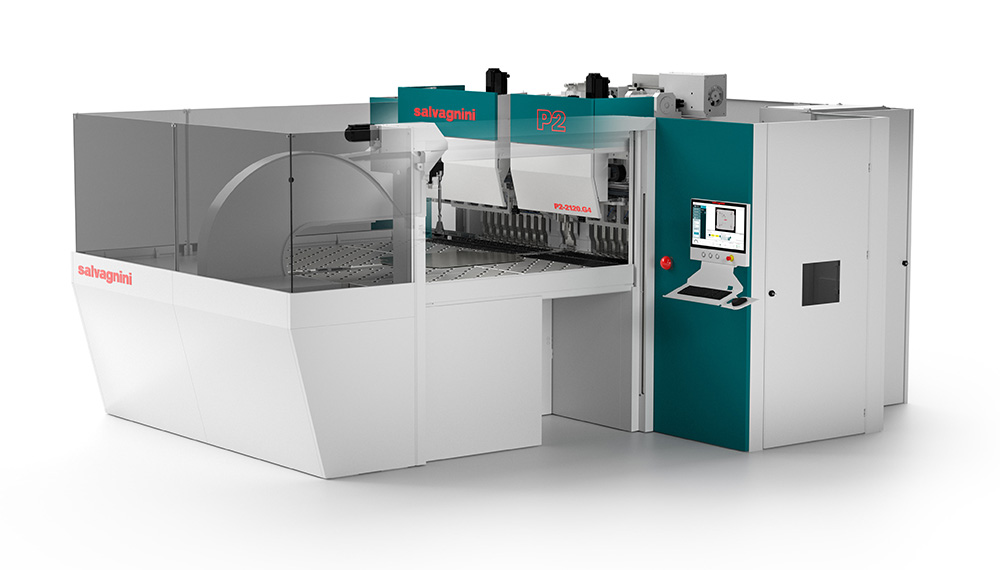

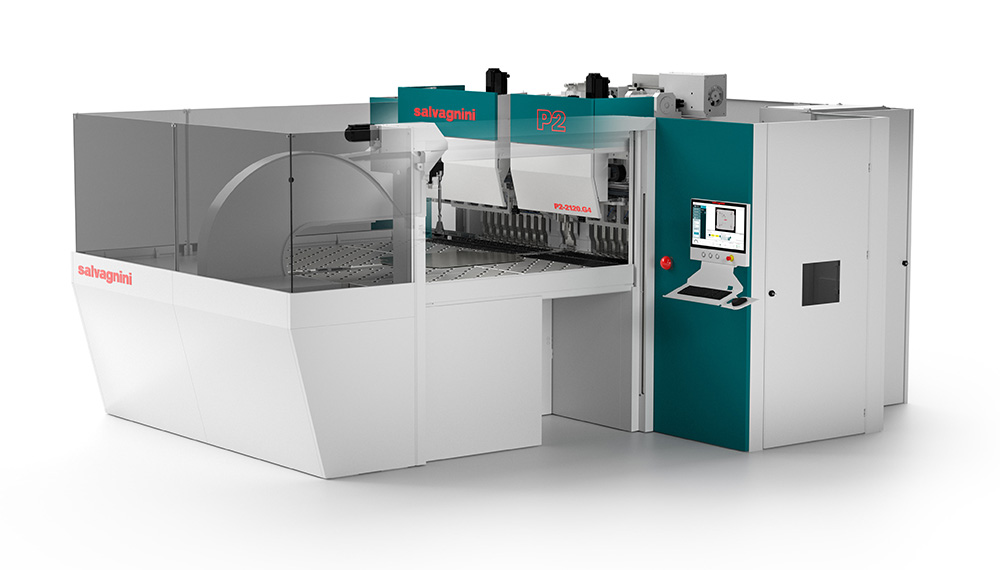

"THE" Panel Bender

Our best selling panel bender. The P2 has innovative technology that offers unbeatable productivity, flexibility, and is energy-efficient.

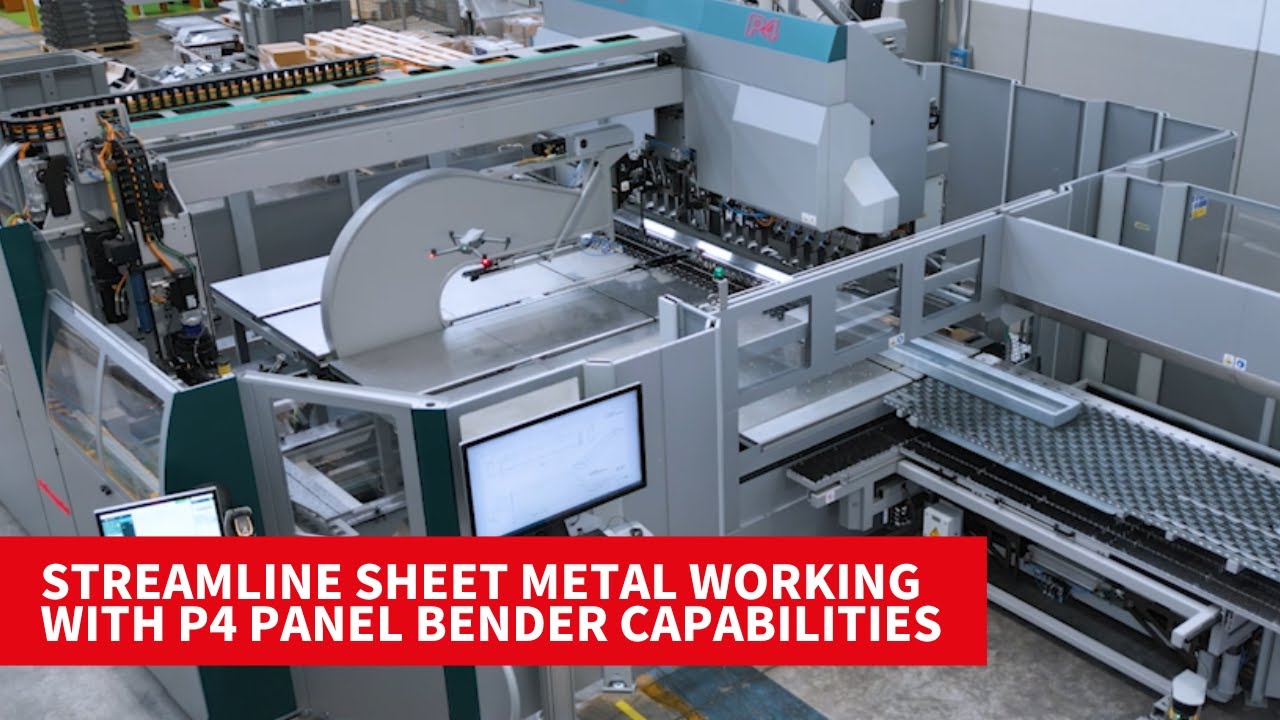

Maximum Versatility

The P4 can be set up independently or be installed in an automated production line. Offering maximum productivity.

Every Salvagnini panel bender offers

Easier bending

Simplifies operations, reduces strenuous tasks, and creates a more welcoming work environment, making staffing easier.

High productivity

Bend at speeds of up to 17 bends per minute, ensuring peak efficiency and continuous production while lowering labor costs without overtime or additional shifts.

Smart programming

The intuitive STREAM software and user-friendly FACE interface enable fast, precise programming, reducing errors and optimizing production time.

Extreme performance

Higher output, consistent quality, 100% repeatability with every bend.

Optimized material usage

Top precision sheet metal bending with minimal waste.

Predictable costs

Automated bending streamlines production management, enhancing cost control with greater safety and reliability.

Seamless production changes

Adapt instantly to different materials and items, and to batch-one and high-mix production.

Effortless automation

Automatic tool adjustments and handling, reducing manual intervention.

Compact footprint

High performance even in compact layouts, ideal for space-constrained companies.

More information?

Do you have specific questions or need further details? We’re here to help.

Contact us to learn more about how Salvagnini can support your production needs.

Operating mode: simple, quick and lean

Bending on each side of the sheet is achieved thanks to the controlled interpolated movements of the blades.

Flexible automation

Upper and lower blade, counterblade and blankholder are the four universal tools used to process the whole range of thicknesses and machinable materials, from 0.4 to 3.2 mm, during the cycle and without machine down times or manual re-tooling.

Proprietary bending formula

Developed over the years, the bending formula defines the force and manages the movements of the universal tools, analyzing different parameters in real time, including deflections, temperature and thickness, guaranteeing the precision, repeatability and quality of the finished product.

Automatic manipulator: fast and accurate

Quickly and fully automatically, this moves, handles, grips and rotates the sheet metal throughout the whole machining cycle. It requires no manual interventions during the cycle. The operator positions the sheet metal on the worktable and collects the product after bending, performing only the loading and unloading operations.

P-Robot

P-Robot is the application combining a Salvagnini panel bender with a robot to produce kits, batches, and single parts autonomously.

Thousands of manufacturers trust us to make bending easy.

Contact us, speak with one of our experts and discover how to bring productivity, efficiency, and flexibility to your production.

Trusted by top manufacturers: listen to their experiences

RH Peterson | USA

R.H. Peterson produces high-end outdoor grills and technology plays a vital role in their manufacturing process. By adopting advanced automation systems from Salvanini, R.H. Peterson has significantly improved efficiency, reducing setup times from 30 minutes to mere seconds and maintaining high uptime for quick order fulfillment. There is emphasis on the importance of technology in remaining competitive and flexible, ensuring the company continues to deliver premium products to its customers.

Antunes| USA

Antunes, known for its custom countertop cooking solutions, improved production efficiency and product quality by leveraging Salvagnini's P2 technology, leading to innovative redesigns and streamlined processes. This collaboration enabled Antunes to adapt swiftly during COVID-19, expand its operations, and contribute to charitable initiatives such as creating a lighter, tamper-resistant cabinet for water filtration systems.

Technical data

| Model | P1 | PX* | P2 | P4 |

| Maximum length of incoming sheet (mm) | 1575 | 2495 | Range | Range |

| Maximum width of incoming sheet (mm) | 1000 | 1600 | Range | 1524 |

| Maximum diagonal that can be rotated (mm) | 1600 | 2500 | Range | Range |

| Maximum bending force (kN) | 90 | 330 | Range | Range |

| Maximum clamping force (kN) | 310 | 530 | Range | Range |

| Maximum bending length (mm) | 1250 | 2180 | Range | Range |

| Maximum bending height (mm) | 127 | 203 | Range | Range |

| Minimum thickness (mm) | 0.4 | 0.5 | 0.4 | 0.5 |

| Maximum thickness and bending angle steel, UTS 410 N/mm2 (mm) | Max 1.60 (±90°) | Max 2.5 (±90°) | Max 3.2 (±90°) | Max 3.2 (±90°) |

| Maximum thickness and bending angle stainless steel, UTS 660 N/mm2 (mm) | Max 1.30 (±90°) | Max 2.1 (±90°) | Max 2.5 (±90°) | Max 2.5 (±90°) |

| Maximum thickness and bending angle aluminium, UTS 265 N/mm2 (mm) | Max 1.60 (±120°) | Max 3.5 (±90°) | Max 3.5 (±120°) | Max 4.0 (±120°) |

Values refer to a standard machine. Salvagnini reserves the right to modify this data without warning.

Full technical specifications are available on each panel bender's page.

*The PX is currently only available in Mexico for North America.

Choose Your Panel Bender

Compact & Optimized

The P1 is our entry level panel bender, With its automatic bending and handling cycles, it offers unparalleled productivity and flexibility.

"THE" Panel Bender

Our best selling panel bender. The P2 has innovative technology that offers unbeatable productivity, flexibility, and is energy-efficient.

Maximum Versatility

The P4 can be set up independently or be installed in an automated production line. Offering maximum performance and productivity.

More information?

Do you have specific questions or need further details? We’re here to help.

Contact us to learn more about how Salvagnini can support your production needs.