We care about

Sustainability,

according to us

Continuous environmental, social and economic wealth over time: this is the ultimate meaning of sustainability, which aims to prevent the depletion of resources so that they can remain available in the long term.

And which perfectly represents the widespread sustainability that we have chosen to pursue by adopting environmental protection and energy management standards, extending the same approach also to the design of our machinery, staff training, optimization of processes and rationalization of the supply chain.

How the continuous innovation of our products has reduced their environmental impact

80

Energy

Compared to the 2002 models, today’s machines consume 80% less energy

00

Chemicals

Paints with no organic solvents or dyes with heavy metals

95

Oil

Compared to the 2002 models, today’s machines use 95% less oil

20

Years

Long life cycle: today over 30% of the machines which were installed over 20 years ago is still in use

Sustainability is bound to the circular economy

Our products are designed for long life, and to be reused, renovated, regenerated and finally recycled. Transforming goods that have reached the end of their life cycle helps to minimize waste, further reducing the consumption of energy and raw materials.

Our circular approach

Our machinery and systems consist mostly of mechanical parts made of steel, a 100% recyclable material, and can be fully recovered at the end of their life. Around 85% of these components are sent for recycling, while the remaining 15% are used as spare parts.

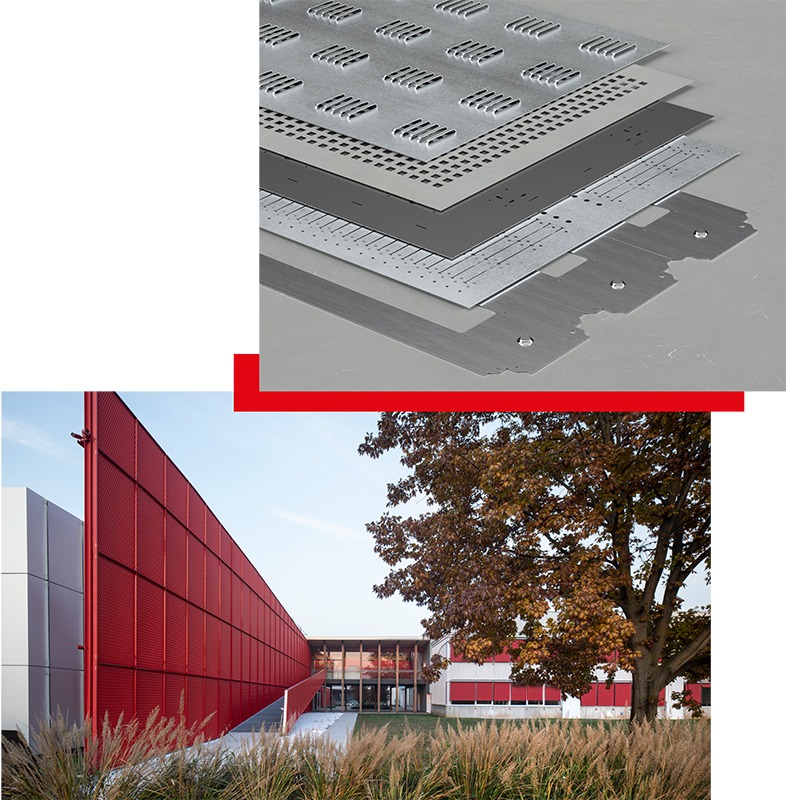

Architecturally sustainable: the Sarego Campus

The two buildings are made from recyclable materials and do not consume more land, as they were re-industrialized on an abandoned site. An extremely careful design led to the construction of modular, prefabricated units, which are easy to assemble and disassemble, with no material waste. A 180kW photovoltaic system and the wise use of natural light also reduce the environmental impact. The design helps to harmonize the industrial area with the surrounding agricultural landscape.

The same design and construction logics were applied to the Campus in Hamilton (Ohio, USA), where Salvagnini America has its headquarters.

Sustainability and circularity, all the way

Our green, circular approach has also been extended to the supply chain, packaging and transportation. By rationalizing transport and deliveries, much of the packaging has been eliminated, while the number of goods receipts, the related paper documentation and the distance traveled by the carriers have all been reduced to a minimum. For years, we have been using packaging made from wood, a natural material that is 100% recyclable.