Punching machines

High-performance sheet metal punching machines for flexible, cost-efficient production

Salvagnini sheet metal punching machines integrate multiple processes in a single, compact work center - punching, forming, tapping, laser cutting or part separation - to shorten lead times and reduce cost per part. At the core of Salvagnini’s sheet metal punching machines is the patented multi-press head: a concept that keeps a wide set of tools permanently and immediately available. The tool selection doesn't require turret rotation or manual changeover: these machines run with near-zero setup, higher uptime, and consistent quality across mixed materials and thicknesses. The multi-press head improves repeatability, edge finish, and tool life while limiting operator influence, advancing the performance of modern sheet metal punching machines. Salvagnini laser punching machines and punching shearing machines provide the productivity of a single work center with the flexibility to run large batches, kits, or batch-one with equal ease, minimizing intermediate handling and scrap while ensuring accuracy and repeatability typical of high-end punching machinery.

From smart punching to full punching automation

Salvagnini’s punching and punch-laser combination machines scale from stand-alone operation to fully automated systems with modular automation for loading, unloading, and part sorting. Options include pack and tray destackers, single-sheet store-towers for just-in-time material availability and ultra-fast changeovers, and tray stackers. Part sorting, both for stand-alone and in-line machines, can be managed by various devices with different capabilities and specifications, covering both large and small components and enabling end-to-end traceability even in complex production environments. Open to downstream processes, these sheet metal punching machines integrate seamlessly with panel benders and press brakes to streamline end-to-end flow from punching or laser-punching through bending. Together, these capabilities raise uptime, shrink changeovers, and maximize ROI for modern automatic sheet metal punching automation.

Product range

S1 is a punch-laser combi machine, a true work center that punches, forms, taps, and cuts parts.

Learn more

S4Xe is the world-famous combined punching-shearing center, a legendary machine that has continued to evolve since 1978 and, now as then, guarantees maximum precision, minimum waste, and high efficiency.

Learn more

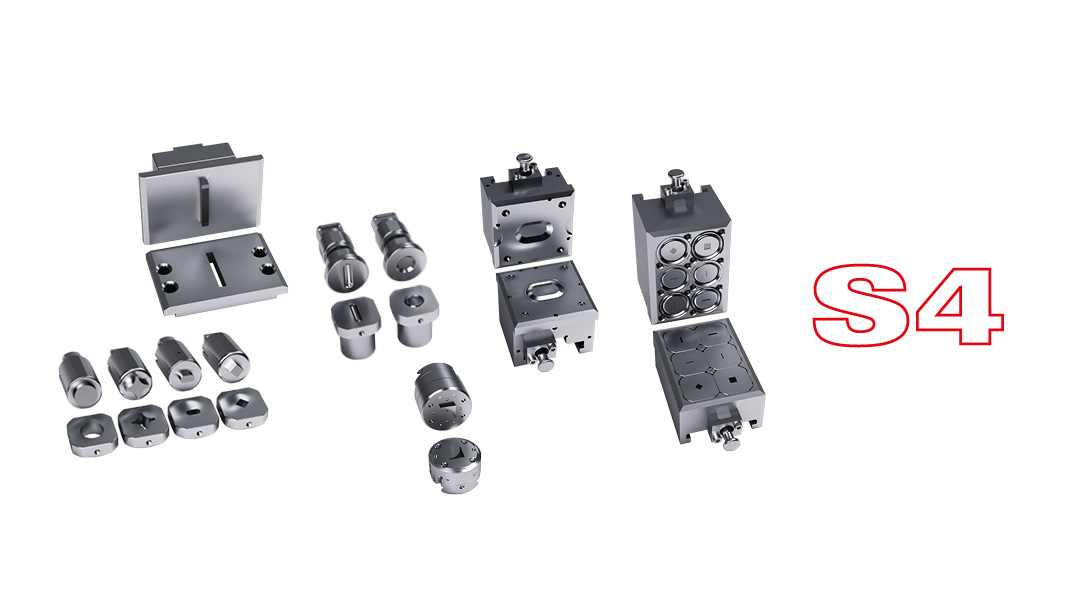

Introducing the Salvagnini S4: a hybrid punching-shearing machine offering unmatched productivity, efficiency, and flexibility.

Learn moreMulti-press head: tools always available

The multi-press head has a die-structure that houses several tools. Each tool is actuated individually and is always available. The multi-press head guarantees high punch-die alignment precision with reduced cycle times, eliminating in-cycle set-ups and the related waiting times.

Salvagnini tools

With thirty years’ experience in tool design and production, Salvagnini oversees the whole manufacturing chain, from the control of the steels used to mechanical machining and assembly, with its own team of professionals.

Modular, scalable automation for regaining efficiency

Automation plays an increasingly key role. Salvagnini loading/unloading and sorting connections satisfy all automation requirements: from stand-alone operation, to integration in flexible cells or in automatic lights-out factories.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the punching machine. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Do you have any questions?