STREAM is the integrated ecosystem for managing all activities in the office and on the factory floor, the only point of access for all technologies, from cutting to bending, meeting all planning, programming, production, management, control, and optimization needs throughout the production process. STREAM includes 5 CAM modules associated with each individual technology, the data library software PARTS and the quotation software VALUES.

What software are you looking for?

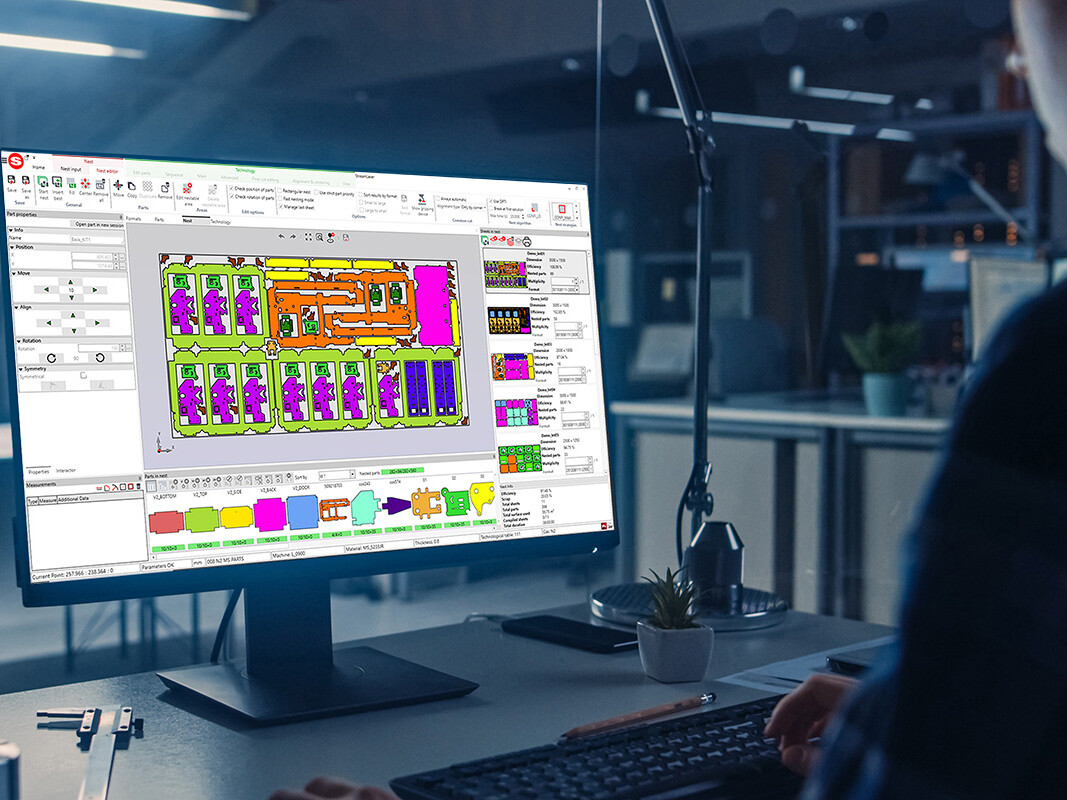

STREAMLASER is the programming software for generating cutting programs. It includes the following functions:

- CAM: creates or allows editing of the 2D model, automatically defines lead-ins and cutting sequences, and calculates the processing path, allowing for manual intervention.

- Nesting: automatically, semi-automatically or manually optimizes sheet composition starting from a list of parts to be produced.

- Reverse engineering: generates the drawing starting from the program.

- OPTI: optimizes the use of the sheet and repeatability of the diagrams, minimizing the variability of the nesting layouts.

- Parametric shapes: easily and quickly prepares programs and prototypes without starting from a drawing.

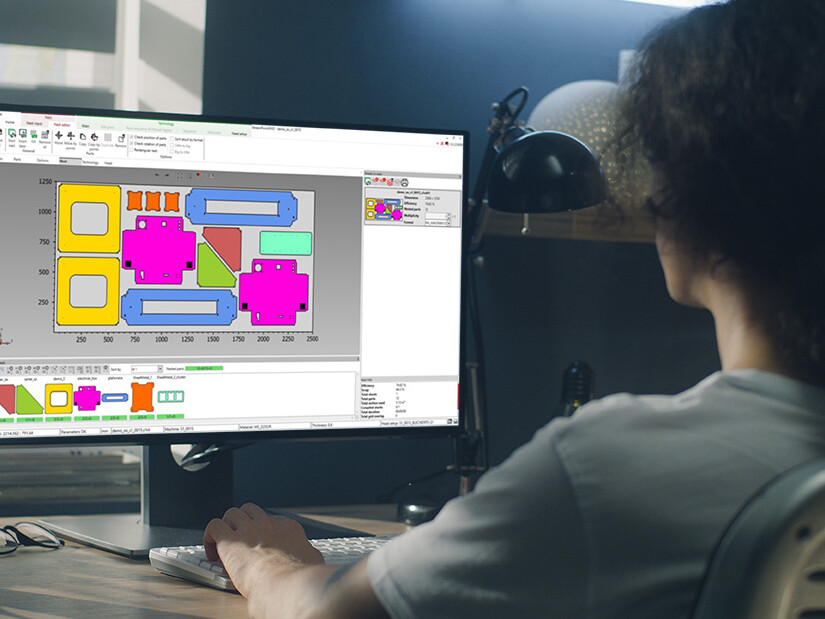

STREAMPUNCH is the programming software for generating punching programs. It includes the following functions:

- CAM: creates or edits the 2D drawing of the part, and automatically defines the punches for creating the geometries, punching and shearing sequences and sheet metal handling operations.

- Nesting: automatically, semi-automatically or manually optimizes the sheets for production, starting from a production list.

- Reverse engineering: generates the part drawing from the machine program.

- OPTI: optimizes the use of the sheet, increasing process efficiency and minimizing waste.

- Parametric shapes: compiles nests from programs with parametric variables, without using a 2D drawing.

STREAM.COMBI is the programming software for generating punching and cutting programs. It includes the following functions:

- CAM: creates or edits the 2D drawing of the part, and automatically defines the punches for creating the geometries, punching and laser cutting sequences and sheet metal handling operations.

- Nesting: automatically, semi-automatically or manually optimizes the sheets for production, starting from a production list.

- OPTI: optimizes the use of the metal sheet, increasing process efficiency and minimizing waste.

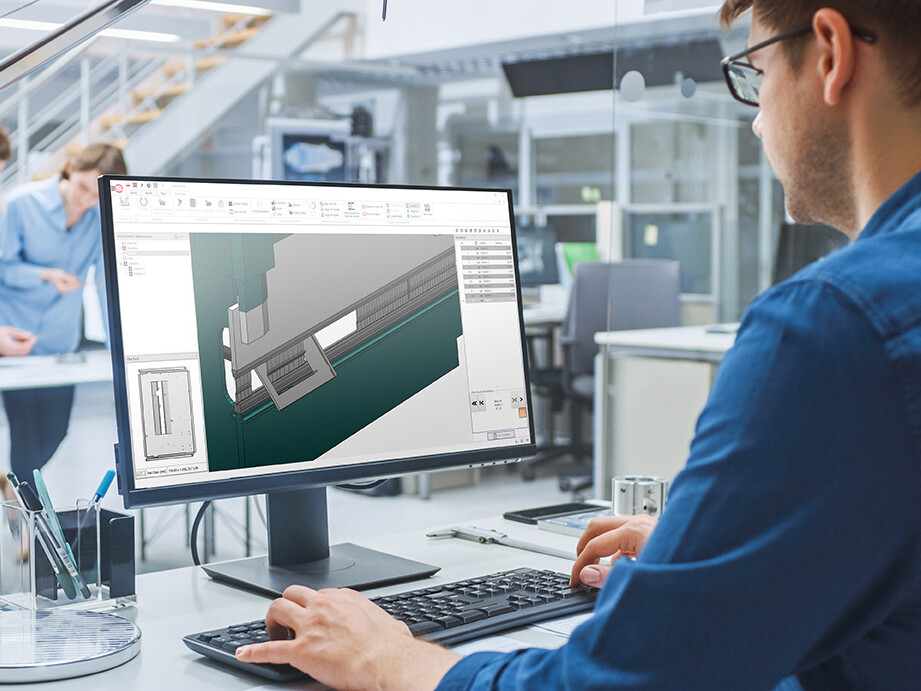

STREAMBEND is the software for developing panel bending programs, including multiple parts:

- automatic mode: develops programs independently, starting from a 3D model;

- interactive mode: used for generation/editing/completion operations;

- simulator: virtually assesses the results obtained on the machine.

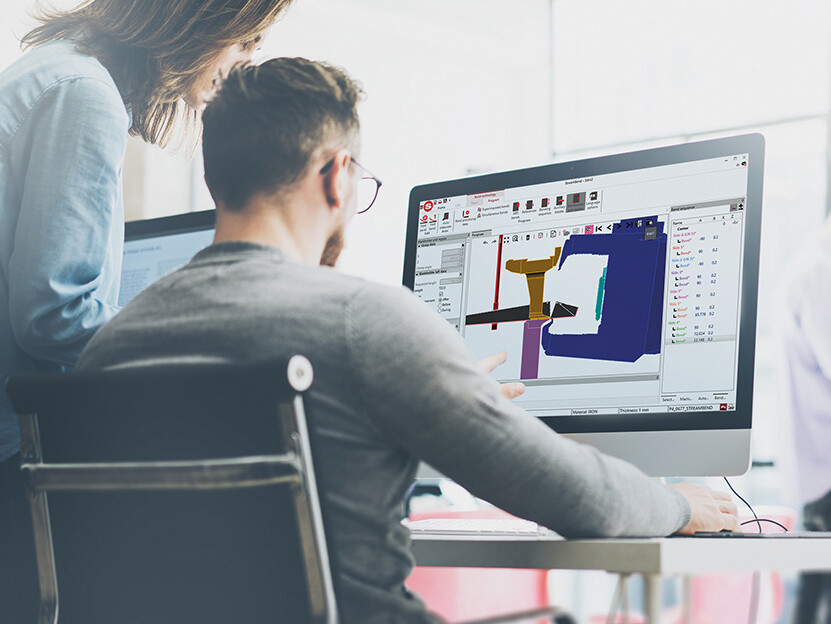

STREAMFORMER is the software for developing press-brake programs, including multiple parts:

- automatic mode: develops programs independently, starting from a 3D model;

- interactive mode: used for generation/editing/completion operations;

- simulator: virtually assesses the results obtained on the machine.

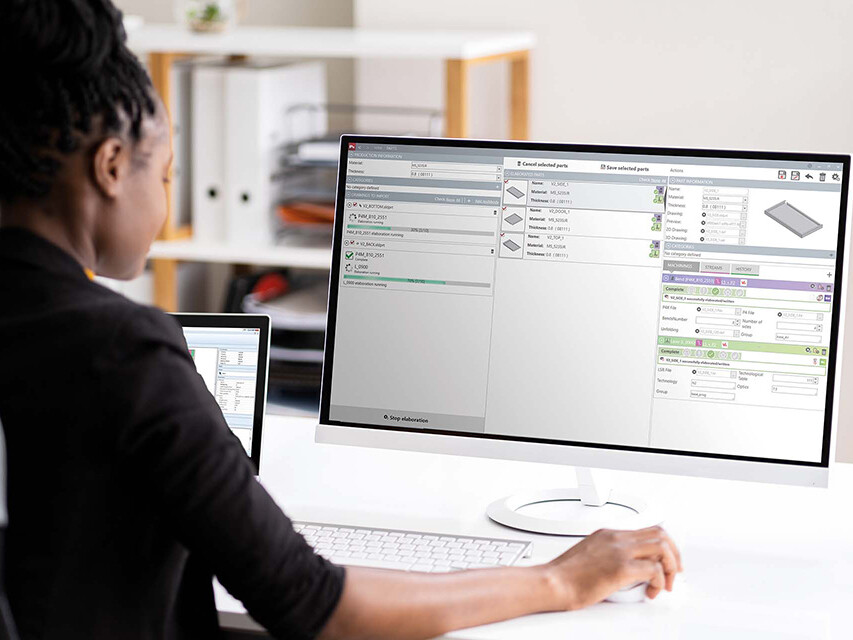

PARTS is the software used to manage the whole database of products and parts:

- it classifies the elements according to common or customized categories;

- it defines the production flows for each part to be machined;

- it generates the relative program.

VALUES is the software which provides an accurate estimation of production costs.

It allows cost estimations on individual technologies and entire production processes, including upstream and downstream machining where necessary.

Do you have any questions?