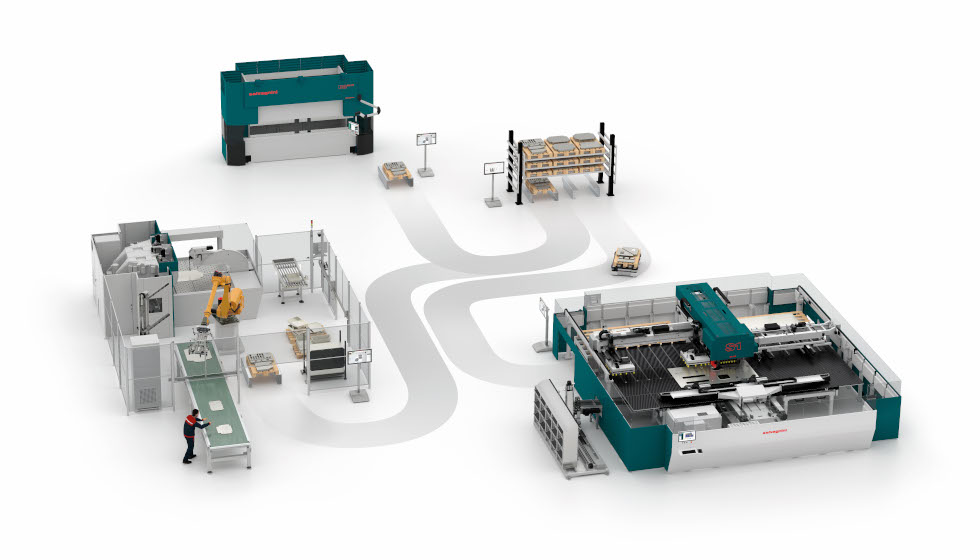

Introducing Flexible Smart Job Shop: the intelligent ecosystem for flexible, dynamic production

The Flexible Smart Job Shop (FSJ) is a combination of stand-alone machines that process sheet metal autonomously or in cooperative mode, integrated by software, artificial intelligence and vision (AI) solutions, robotics and automation to dynamically tackle modern market challenges.

At Blechexpo 2025, Salvagnini proposes a Flexible Smart Job Shop consisting of:

The S1 is the Salvagnini punch-laser combi machine that integrates punching, forming, tapping, laser cutting and part separation in a single system. This advanced solution is designed to concentrate a variety of activities traditionally done on several machines in a single step, reducing throughput times, intermediate handling and manual intervention.

The Smart Warehouse is an intermediate storage completely managed by OPS software, positioned between punching/cutting and bending.

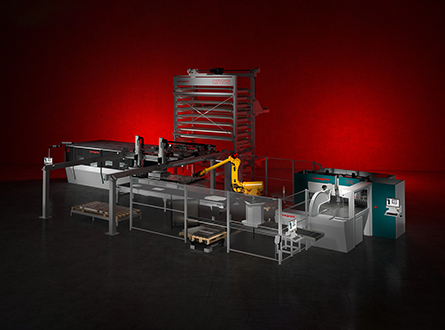

P-Robot is the Salvagnini application which combines a panel bender with a robot to produce kits, batches and single parts. The P-Robot on display in Stuttgart includes some interesting new features to improve process autonomy and reliability.

RVS (Robot Vision System) exploits the patented 3D artificial vision system to further simplify the use of the technology, optimize the production flows by accelerating the intermediate recognition, handling and programming steps – and maximizing the value of the finished part with the quality control system.

Automatic set-up and tool change are the two most obvious strengths of B3.AU-TO, the Salvagnini press brake. B3.AU-TO extends the availability, autonomy and flexibility of the press brake.

Explore the technologies on display

The Flexible Smart Job Shop (FSJ) is a combination of advanced technologies, software, artificial intelligence and vision (AI), robotic and automation solutions for dynamically facing the challenges of the modern market.

자세히 알아보기

Tickets

Get your complimentary ticket by clicking here!