Case study

Higher quality in less time

Story courtesy of E. Weustink/PlaatBewerkingsNieuws

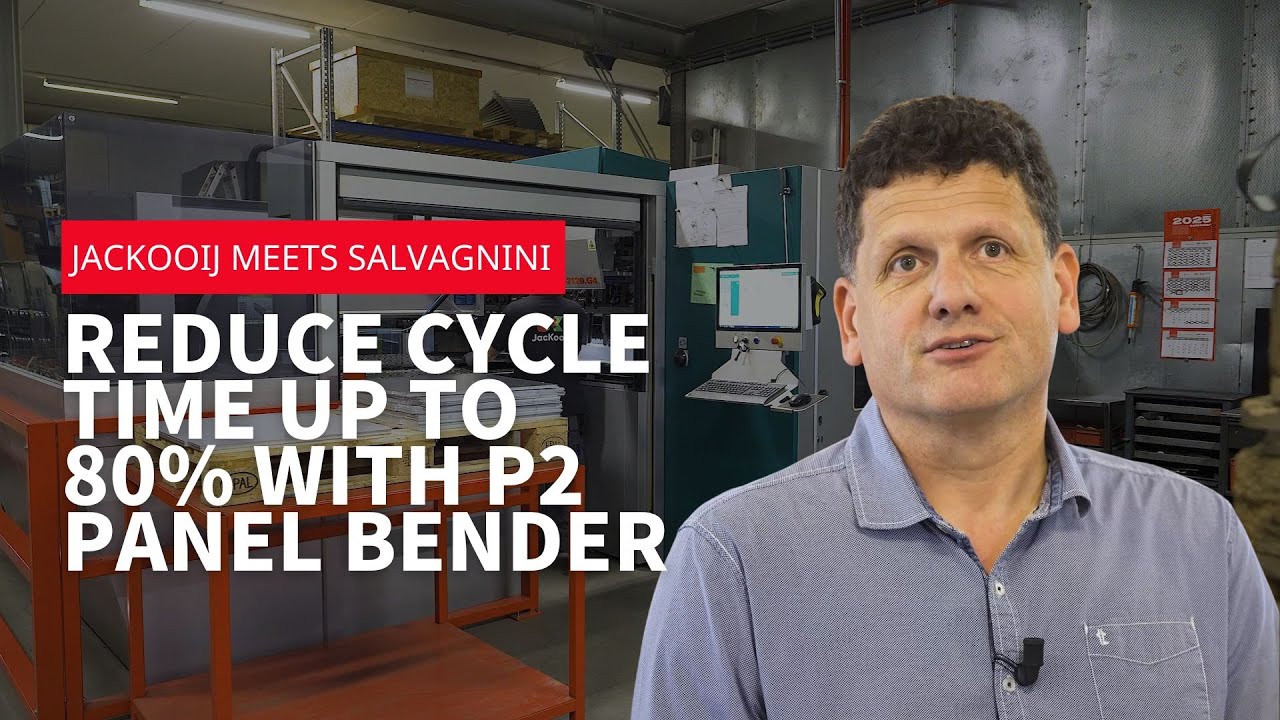

Since commissioning a Salvagnini P2 panel bender, bending is no longer a bottleneck at JacKooij in Aalsmeer. The machine has now been in operation for two years and the results have exceeded expectations. "It is incredible how much time we are saving," says the Managing Director and owner, Onno Kooij. "We can produce much more with fewer people, and the quality of the parts has significantly improved."

Higher quality in less time

Highlights

- JacKooij

JacKooij is a third-generation metalworking company in Aalsmeer, founded in 1947, employing about 55 people. It delivers complete, pallet-sized products, mainly retail displays for supermarkets and fashion brands, plus aircraft trolleys, handling around 500 tons of 1–3 mm sheet metal per year with in-house engineering, fabrication, finishing, and assembly. - The challenge

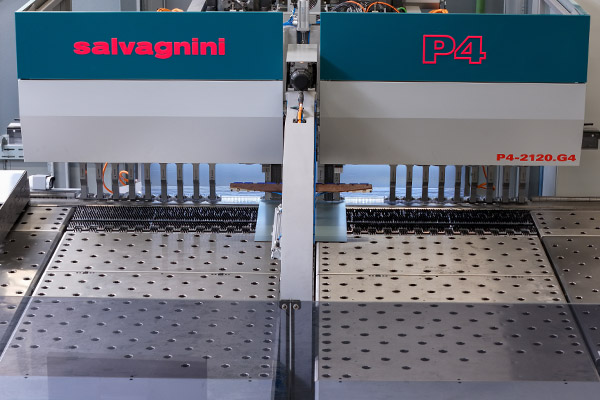

Bending had become the constraint: press brakes and an old panel bender could not keep up, and the work was too repetitive to staff five days a week. With up to 200 different products in a month, JacKooij needed fast changeovers and high flexibility, something a robotized press brake could not deliver due to slow changeover, limited speed, and flexibility. - The solution

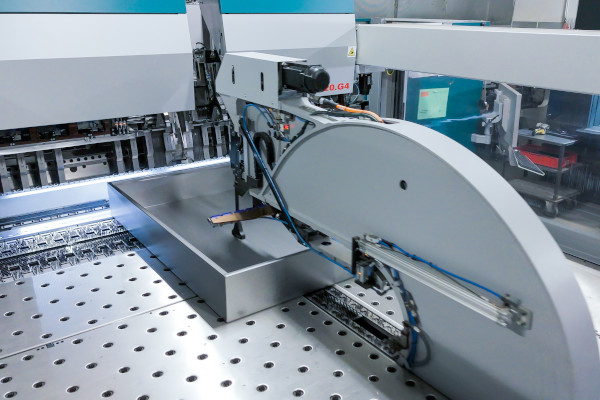

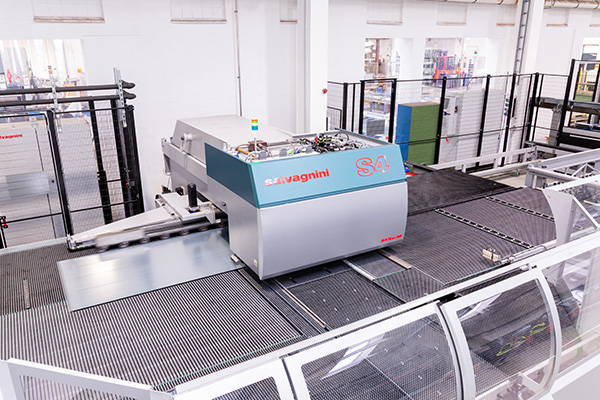

JacKooij commissioned a Salvagnini P2 panel bender to replace traditional bending, selecting it for its compact footprint and speed. With tool changeovers in seconds and the CUT option, the P2 can bend multiple parts from a single sheet and automatically cut strips and U-profiles to length. Operation is program-driven: load, start, run. - The results

Two years after commissioning, the P2 removed bending as a bottleneck: backlogs fell and output increased, while staffing dropped from three to one. "We can produce much more with fewer people, and the quality of the parts has significantly improved," says Onno Kooij, Managing Director and owner.

Check out the case study

Hear what Onno Kooij, Managing Director and owner at JacKooij, says about the P2 panel bender.