Case study

From flexibility to lights-out: how Dimitroulakos scaled metal furniture production with Salvagnini

Dimitroulakos S.A., a Greek manufacturer of shelving and metal furniture, shifted from conventional bending to a flexible, automated model built around Salvagnini technology. From the first PERformER panel bender to the latest P-Robot featuring a P2, the company standardized quality, unlocked batch-one agility and unmanned hours, and simplified upstream and downstream flows improving lead times, widening the product range, and reducing dependence on scarce skilled labor.

From flexibility to lights-out

Highlights

- Dimitroulakos

Dimitroulakos S.A. is a Greek manufacturer of shelving and metal furniture, producing office and warehouse systems, retail fixtures, cabinets and wardrobes. It operates three production sites (two in Schimatari and one in Thessaloniki), exports to around a dozen countries, and processes about 4,000 tons of sheet metal into ~400,000 panels per year. - The challenge

Serving a small, customization-driven market meant frequent size changes and batch-one orders, but press brakes and roll-forming created changeovers measured in hours, limiting variants and stretching schedules. The company also needed repeatable bending to stabilize downstream welding and to run more hours with the same team, reducing reliance on scarce specialist labor. - The solution

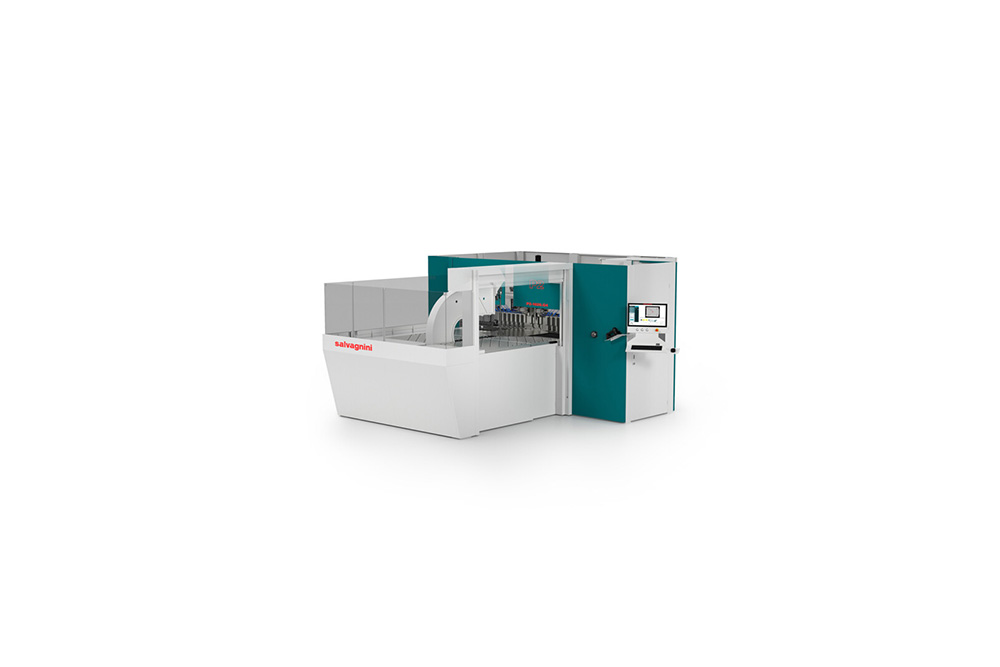

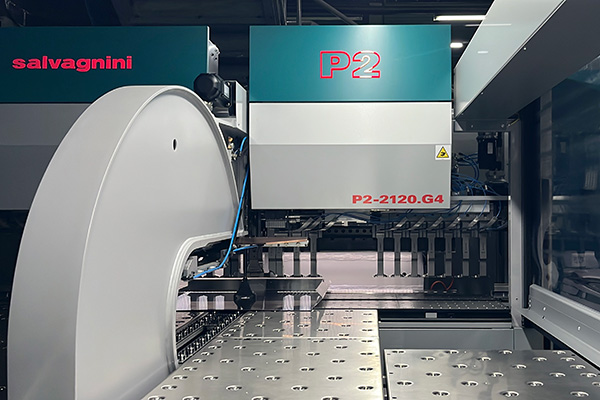

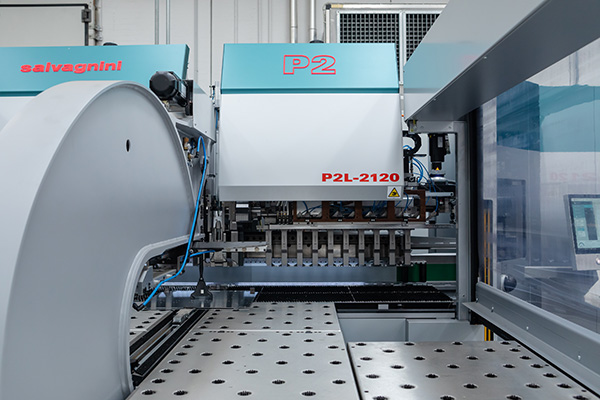

The solution evolved from a 2001 PERformER panel bender to a P4 and, in 2024, a P-Robot with a P2-2120 featuring automatic blankholder, CLA auxiliary blades and the CUT option. Upstream, an Salvagnini fiber lasers with automatic sheet handling support longer unmanned manufacturing and smoother flow from cutting to bending. - The results

"Within six months of installing the PERformER we doubled the sizes we offered," says Stefanos Dimitroulakos, Head of Export and Communication. With the P-Robot, Dimitroulakos can run standard profiles in lights-out mode, feeding more repeatable geometry to robotized welding. CUT also removed handling: "Before the P-Robot we had ten human interactions; now we have one."