Case study

Mazzieri: the synthesis between industry and craftsmanship

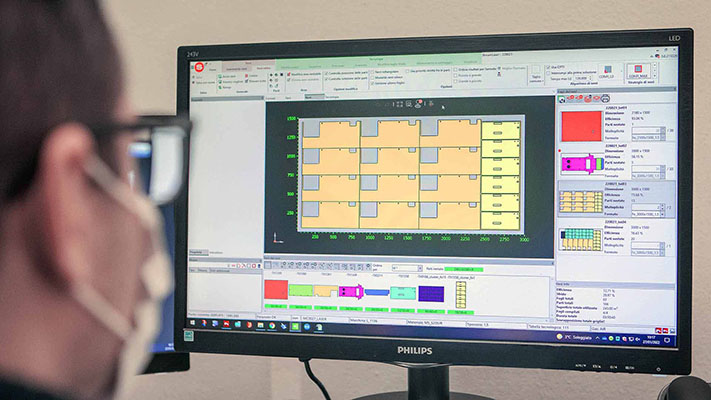

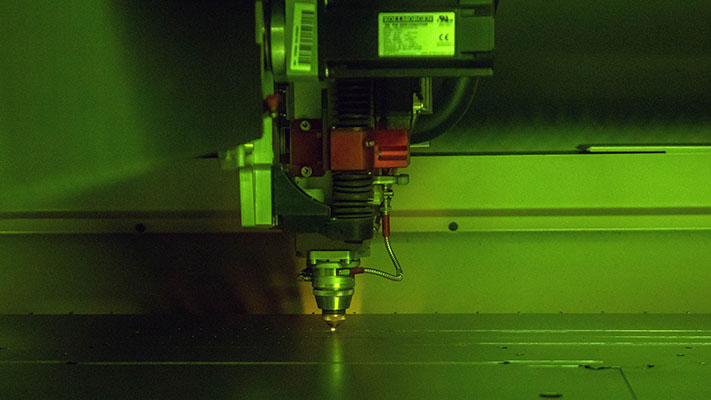

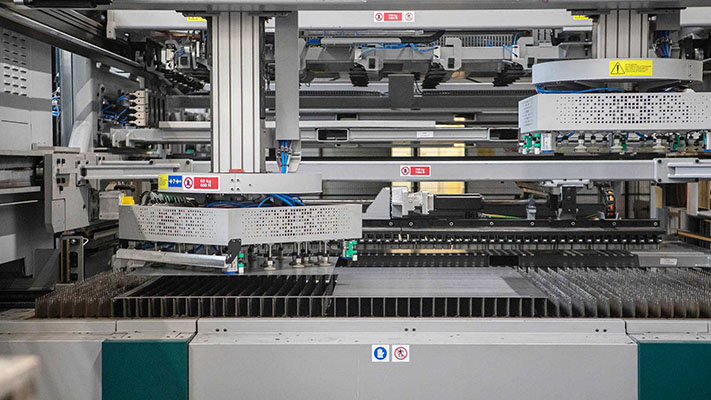

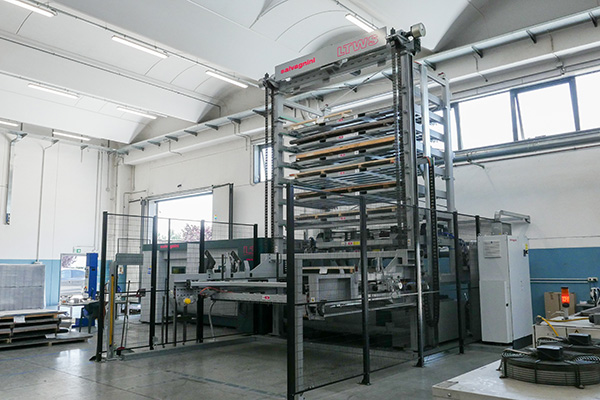

Mazzieri S.r.l. is a renowned name in the design and production of cabinets and structures for electrical panels in painted steel for on-board machine automation, low-voltage distribution and 19” data transmission racks. We met Matteo Mazzieri, one of the partners and the third generation of the family to work in the company, to talk about its latest major purchase: a Salvagnini L3 laser with an LTWS store-tower and MCU automatic sorting device.

The synthesis between industry and craftsmanship

Highlights

- Mazzieri

With 30 employees and a turnover of around €3.5 million, Mazzieri’s production includes cabinets and boxes for switchboards, particularly for industrial automation, which covers around 80% of its total production capacity. - The context

Mazzieri offers a complete catalog of standard products. But the design of tailor-made solutions beyond the catalog range is what receives most attention, and in fact around 70% of production involves some level of customization. - The project

With production focused almost entirely on thicknesses between 10/10 and 30/10, mainly polished and galvanized sheet metal, in 2021 Mazzieri replaced an old disk laser with a new Salvagnini L3 fiber laser system with loading/unloading/sorting automation. - The outcome

"Today around 95% of our production is done with compressed air. The economic advantage is clear, because we have significantly reduced our consumption of nitrogen and oxygen. We have installed a compressor, which in the summer is powered by our 200kW photovoltaic system: we think that the machine has practically no impact on our overall energy consumption for around six months a year," says Matteo Mazzieri.