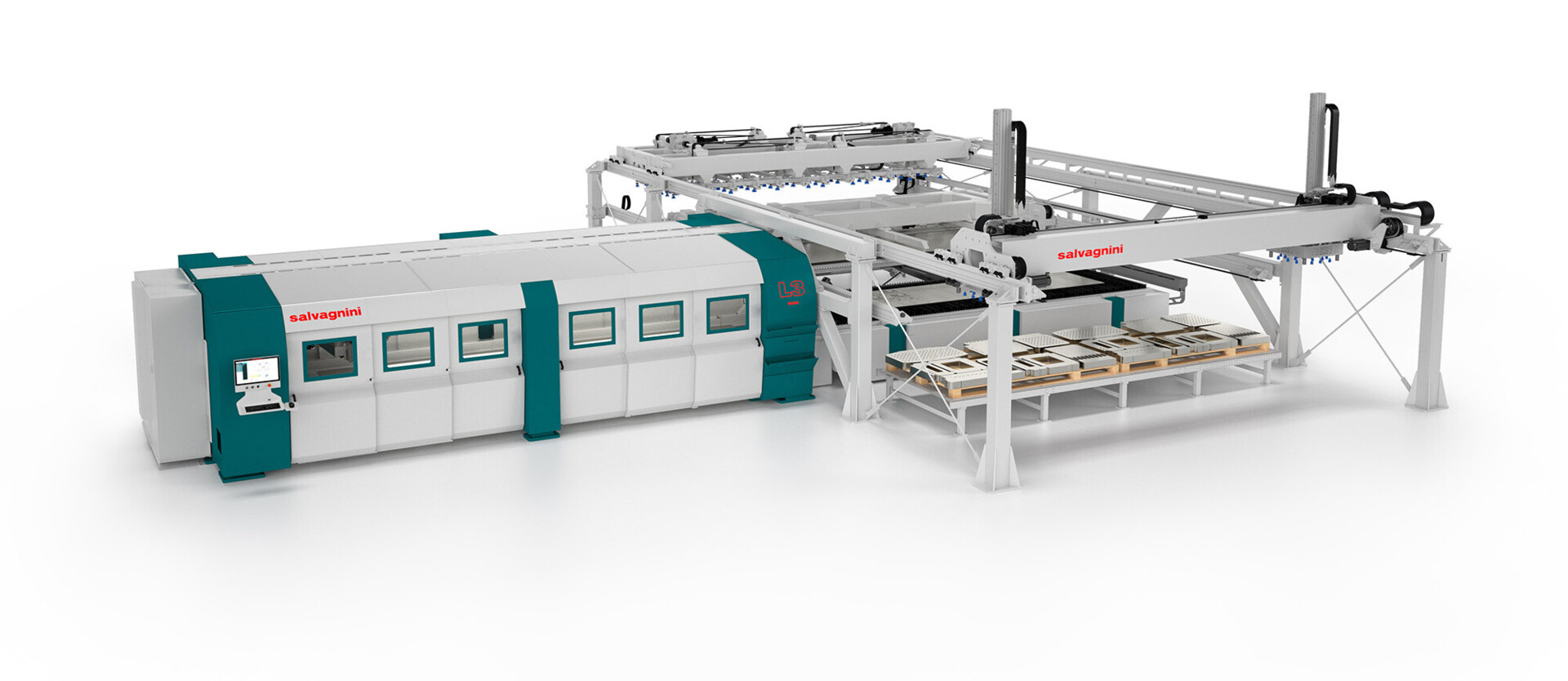

Two automations for the L3 laser in the 6-meter configuration

In the world of laser systems, automation plays an increasingly important role in improving the effectiveness of loading and unloading operations. Larger lasers face even greater challenges than 3- and 4-meter lasers when it comes to these tasks. Whether it's because of the delicacy and size of the sheet or the weight of the material to be handled, it's important to note that as the size of the sheet metal increases, so does the time required for handling, both before and after the cutting process.

This long handling time, is what convinced Salvagnini to develop the ADLU loading/unloading device and the MCU automatic sorting device in size 6020, for processing sheet metal formats of up to 6 meters in length.

ADLU loading/unloading device

In just 60 seconds, the ADLU device automates the process of loading sheet metal from packs and unloading the cut sheets, eliminating all intermediate handling steps that are usually done by the operator. Additionally, the ADLU is a flexible solution in terms of layout, as its modular, floor-based structure can be adapted to the available spaces in the workshop.

MCU automatic sorting device

The MCU automatic sorting device excels at handling parts of various shapes, sizes, and weights. It can work in full multi-gripping mode, picking up several parts in sequence with the same gripping device. It activates the necessary suction cups or magnets individually. MCU uses NEXUS software for its operations.

NEXUS software

NEXUS is user-friendly and straightforward, automatically handling sorting programs. If needed, operators can edit these programs interactively. NEXUS provides full control over the entire production process, including individual sheets at precise points in the cycle. It also offers accurate checking through an integrated 3D simulator. NEXUS eliminates the need to select a specific production strategy during the design phase. It adapts to various requirements, whether it's for large batches, small batches, kits, or one-off batches.

AVC technology

Both ADLU and MCU prioritize sustainability by using AVC (adaptive vacuum control) technology. This technology monitors the vacuum level in the suction cups during gripping and activates vacuum generation only when necessary. This results in a remarkable reduction in compressed air consumption, exceeding 90%.