Case study

Optimel AB invests in Salvagnini’s S1 punch-laser combination machine

Story and pictures courtesy of Tidningen Maskinoperatören

Optimel AB, based in Uppsala, is a well-established manufacturer specialised in sheet metal processing. Founded in 1997, the company supports both large and small customers, taking on everything from serial production to small, highly specialised orders. Its operations cover the full flow, from laser cutting and punching to bending, welding, assembly, and painting, backed by two proprietary product brands that are continuously developed to meet future requirements.

"Our strength lies in customer-specific turnkey solutions, covering everything from design to finished product. One of our concepts is based on pre-assembled workbenches, where customers can choose to configure them in virtually any length they need. Here, we jointly develop a complete solution: Plug and Play with pre-installed power, data, and connection cables, ready to be installed in locations such as a motorcycle or car workshop," says Andrea Doni, Production Manager at Optimel.

"Swedish-made mailboxes in our own factory since 1989. Since introducing the first large folding mailbox on the Swedish market, we have continued to develop our range of mailboxes. We constantly strive to deliver premium products with practical solutions tailored to meet the needs of today and the future in the mail and parcel box segment. With our BOX product concept, we are well prepared for the future of e-commerce logistics. The digital lock from Inside The Box provides customers with many potential uses for their mailbox in the years to come."

Salvagnini, the Italian machine manufacturer, operates globally with a strong focus on innovation in flexible, automated sheet metal technologies, ranging from standard solutions to fully customised FMS Flexible Manufacturing System configurations. In Scandinavia, Salvagnini Scandinavia AB (founded in 1988) supports the full lifecycle through its headquarters and showroom in Värnamo, Sweden.

"We often carry out an analysis at the companies, acting like a business consultant to advise on the needs each company has or may desire. This way, with the right equipment and staffing, they can meet the future market competitively. We normally focus on processes and solutions before discussing machines," says Erik Arden, Sales Manager, Salvagnini Scandinavia.

Why S1: a compact work centre for punching + fibre laser cutting

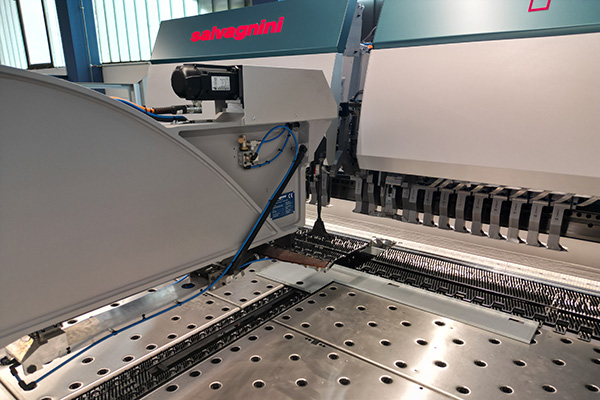

Optimel has now taken the next step, becoming the first company in Sweden to invest in the new Salvagnini S1 punch-laser combination machine. As a true work centre, the S1 brings sheet metal punching, forming, tapping, cutting, and part separation into a single, automated system, supporting laser cutting automation while reducing waste, intermediate handling, and operator intervention.

"The S1 is unique with Salvagnini’s well-proven multi-press head, where all punches are always prepared, meaning there are no changeover times between different tools. The S1 can accommodate up to 59 different tools in the multi-press head and six different tapping stations located alongside the punching head. Together with the fibre laser head, this makes the S1 a complete and compact combination machine," continues Arden.

Footprint, sorting, and toolchain control

From a layout perspective, the full installation occupies just 7 × 8 metres including material feeding, sorting, and skeleton handling. Sorting is managed by Salvagnini TM. Equipped with suction cups and magnets that can work independently or together, the TM removes constraints on maximum part size; smaller parts are sorted into bins via a dedicated flap. The full system was installed in spring 2023 and was the first of its kind in Sweden.

On tooling, the multi-press head includes a turret holding 59 tools, each individually activated and always available, supporting precision punching and forming while reducing both cycle and waiting times. Optimel also runs an electric tapping unit mounted alongside the punching head. The turret tools are manufactured by Matrix, which oversees the full production chain for the tools, spanning standard punching/forming tools as well as parametric and special solutions, strengthening repeatability and control in automated sheet metal fabrication.