Case study

Just-in-time production? Done!

Story courtesy of F. Garnero/Tecnolamiera

At Tecno A Group, sheet metal processing is a key step of a structured production process. Thanks to the far-sighted choice of a Salvagnini FSL S4+P4 tailor-made for its specific requirements, the Marche (Italy)-based company has managed to increase the efficiency of its now just-in-time production.

Just-in-time production? Done!

Highlights

- Tecno A

Tecno A, founded in 1998 in the Marche region of Italy, began as a sheet metal subcontractor and evolved into a Group including Order System and Resto Italia. It focuses on innovative, technologically advanced products with strong sheet metal components. - The context

Tecno A operates within a complex industrial structure combining three distinct yet integrated manufacturing identities, all sharing a centralized sheet metal production line. As each business unit grew, the company was faced with “a high level of production variability from the standpoint of materials, batches, quantities and items,” as explained by founder and CEO Andrea Scopa. This variability, along with the need to serve different sectors with high-quality, precise, and aesthetically demanding products, created a pressing need to streamline and coordinate production. - The project

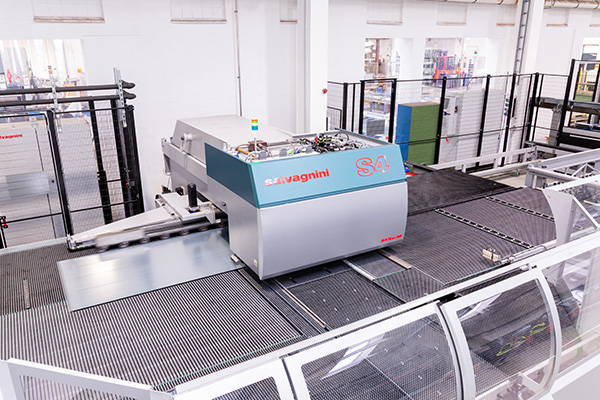

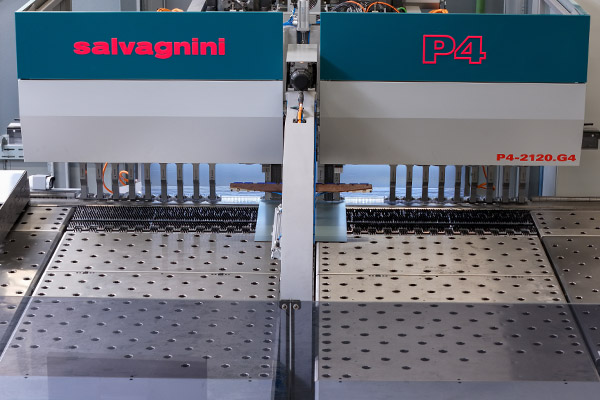

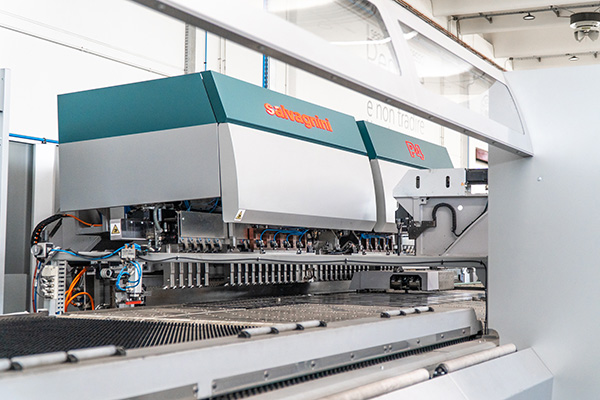

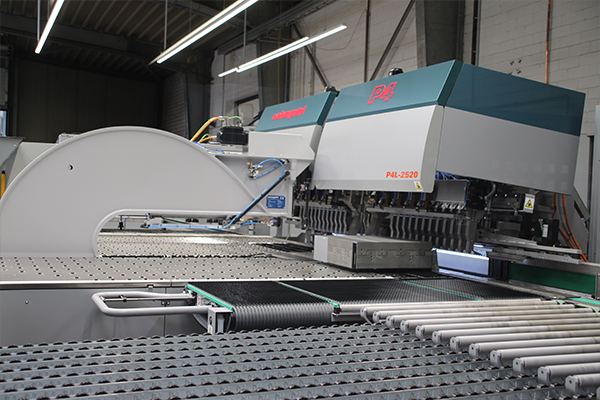

To address this challenge, Tecno A chose to invest in a highly customized automation solution: a Salvagnini Flexible Smart Line FSL S4+P4, integrated with a B3.ATA press brake and an MV store-tower. According to Scopa, “the S4+P4 line is a product which is so advanced that it is ideal for our complex, structured company, and has indeed become the center of our entire production system.” The MV store-tower acts both as raw material storage and an intermediate warehouse for semi-finished parts, enabling dynamic material flow. A key enabler of this setup is the MCU Cartesian manipulator, which connects various machines and stations. “It is what connects the machines which is key to production efficiency, and not the machines themselves,” says Scopa. This intelligent interconnection allows the company to dynamically adapt production routes based on each product’s geometry and process requirements, ensuring minimal manual intervention. - The outcome

The implementation of this flexible, automated system has transformed Tecno A’s manufacturing strategy. Within two years of installation, the company experienced substantial gains: “production has improved dramatically in terms of flexibility, quality, and the ability to manufacture products on a just-in-time basis,” says Scopa. This shift to producing only what is ordered led to a significant reduction in obsolete inventory, lower material waste, and decreased energy consumption. Moreover, the automation enables high responsiveness without compromising precision or quality.