The TN manual sorting device helps operators to separate the cut parts from the skeleton, allowing cutting and sorting to proceed in parallel.

The MCU automatic sorting device is used to easily stack parts of different shapes, sizes and weights. In addition to the standard sorting strategy, MCU can work in multi-gripping mode, picking up several parts in sequence with the same gripping device, or in double-picking mode, reducing the time needed to pick up the parts.

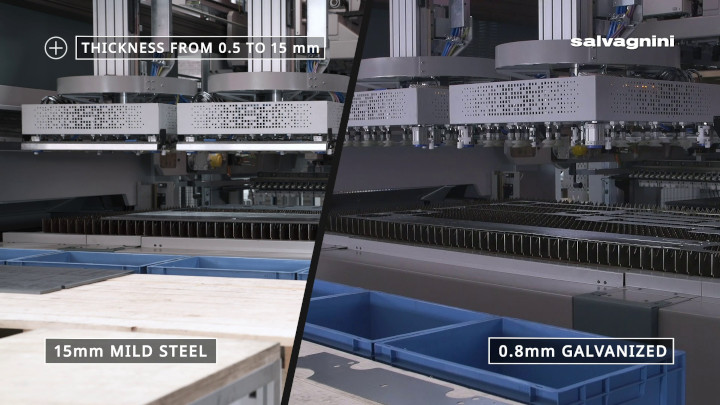

The MCU has very few limits: it can pick up thicknesses of between 0.5 and 15 mm and weights of up to 65 kg for each manipulator, or 130 kg when the two gripping devices work together. The flexibility and extreme mobility of the manipulators, which can rotate a full 360°, removes all geometric constraints: the gripping devices can pick up any part, whatever its maximum size or shape. The minimum dimensions, on the other hand, are 100x200 mm. To overcome the dimensional threshold when unloading parts below the official limits and to prevent automatic sorting from reducing the sheet metal yield, Salvagnini now offers the new smart cluster function. Smart cluster is used to micro-joint parts together quickly and easily, without using a cutting frame and without making programming more complicated in the office. At the same time, smart cluster is yet another solution for reducing total unloading times.

NEXUS, the new Salvagnini software for MCU automatic sorting devices, automatically defines the grips on the parts and automatically generates the unloading sequences and positioning the stacked parts in the unloading areas. The interface is easy to use, allowing manual interaction and fine tuning. NEXUS can be used both in the office and on board the machine.

Do you have any questions?