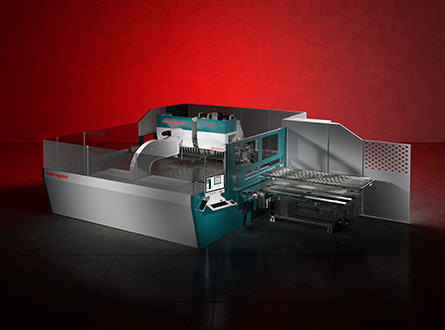

Robotic panel bender P-Robot: an exponential boost in performance

With a compact and modular layout, perfect integration on both hardware and software sides, and easy robot programming P-Robot defines a new paradigm of the panel bender with robot configuration, maximizing its flexibility and productivity.

Robotization to the future

P-Robot is a new application combining a Salvagnini panel bender with a robot to produce kits, batches, and single parts autonomously. P-Robot is a smart solution: easy to program, easy to use, and able to exponentially improve the flexibility and productivity of Salvagnini panel benders.

Application overview

P-Robot can be applied indifferently to standard PX, P2, or P4 panel benders. P-Robot can feature loading/unloading only, can be equipped with devices for automatic movement of the pallets, or can provide third-party integrations – for example with work centers for labeling, laser marking, riveting, welding, and corner forming.

The panel bender uses universal bending tools which automatically adapt in-cycle to the panel geometry, without machine down times or manual retooling, allowing batch-one or kit productions.

The MOVE software acquires the panel bending program, generating automatically the robot trajectories. The operator will simply need to confirm or, if necessary, modify a small number of checking positions to complete the programming of the robot.

P-Robot extends the flexibility and productivity of Salvagnini panel benders because it allows the best strategy to be chosen, based on the current production needs.

P-Robot naturally works in R2R (robot to robot) mode, loading, unloading and, if necessary, stacking the parts. But the same P-Robot can work in different modes, seamlessly and without re-tooling. In R2H (robot to human) mode, it is responsible solely for loading the flat part, whereas the operator is responsible for unloading the panel. In H2R (human to robot) mode, it is the operator who will load the flat part onto the working area, and the robot will unload the panel at the end of the cycle. The panel bender remains also available for any work managed completely by the operator.

P-Robot extends the flexibility and productivity of Salvagnini panel benders because it allows the best strategy to be chosen, based on the current production needs. The same P-Robot can work in different modes, seamlessly and without re-tooling.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the panel bender. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Explore our full range of panel benders

The PX natively combines productivity, with its automatic bending cycles, with flexibility, using universal bending tools. For uncompromising performance.

Learn more

The P2 seduces with its high technological content, low energy consumption and compact layout, without forgetting the productivity and flexibility typical of Salvagnini panel benders.

Learn more

The P4 amazes with its configuration potential and performance: productive and flexible, it can be independent, work in a flexible cell or be installed in an automatic factory.

Learn more