Case study

Rethinking subcontracting with smart bending

In a fast-paced, high-mix manufacturing environment, Unifabs set out to turn bending into a competitive edge. By integrating two Salvagnini P2 panel benders into its production flow, the UK-based subcontractor transformed its sheet metal operations boosting flexibility, accelerating delivery, and unlocking new design possibilities. A strategic shift from capacity challenges to capability-driven growth.

Rethinking subcontracting with smart bending

Highlights

- Unifabs

Founded in 2007 in Nuneaton, UK, Unifabs is a fast-growing subcontract manufacturer offering end-to-end services including design, cutting, forming, welding, coating, assembly, and logistics. With 160 employees and £16M turnover, it focuses on value-added production partnerships. - The challenge

Faced with growing demand, labor shortages, and the need for consistent quality across shifts, Unifabs aimed to boost bending productivity, reduce reliance on skilled operators, and enhance flexibility for high-mix, low-volume jobs. - The solution

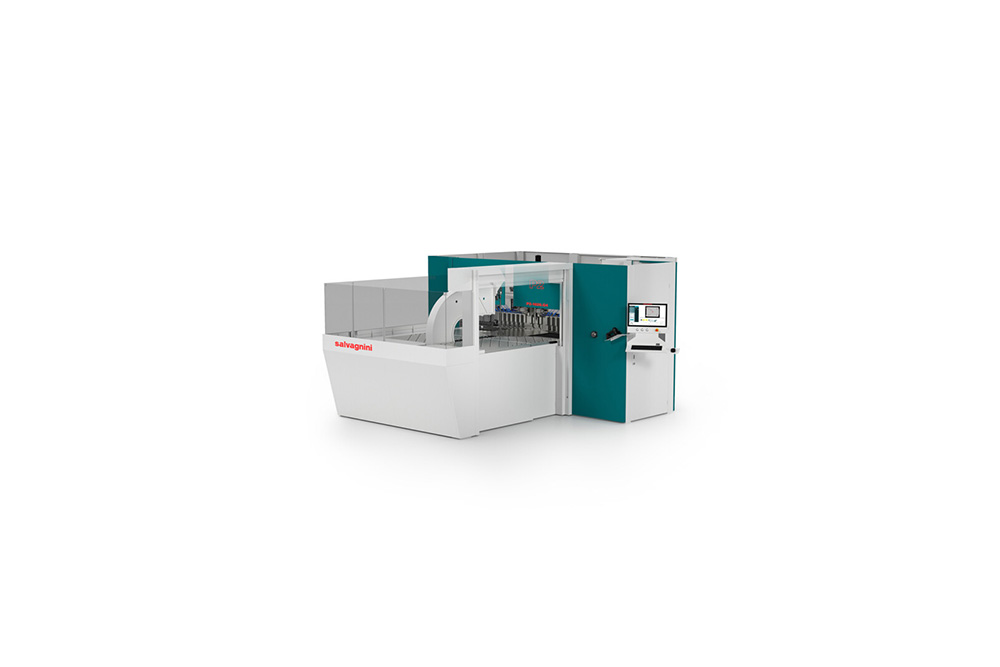

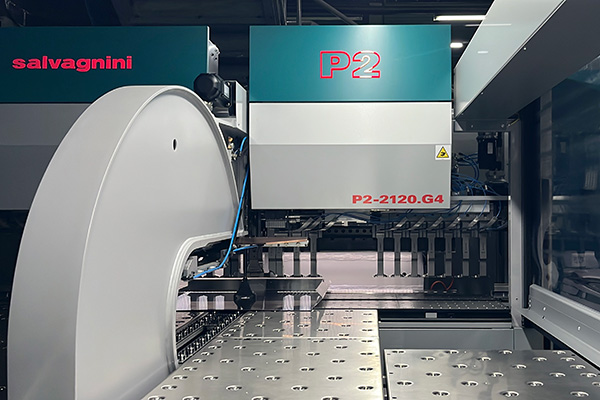

Unifabs installed two Salvagnini P2 panel benders:

• P2-2516 fully equipped with CLA, P Tool, RSU, DPM

• P2-2120 with CLA only - The results

• Up to 17 bends/min with no retooling

• Reduced onboarding time for new operators

• Shorter cycle times compared to press brakes

• Redesigned parts with fewer welds and greater structural integrity

• Improved efficiency, reliability, and customer confidence