Case study

Custom products, but standardized!

Story courtesy of F. Cavaliere and S. Raimondi/Tecnolamiera

With a production logic aimed at rationalizing production, CO.IM.A. has successfully optimized its processes and has also been able to win over the foreign market by offering reliable solutions with reduced delivery times, leaving a fully new mark on the market of extraction systems. An innovative Salvagnini FMS is the technological core around which the company’s entire production process is built.

Custom products, but standardized!

Highlights

- CO.IM.A.

CO.IM.A. designs and builds extraction and filtration systems from Fano, Italy, serving customers from small workshops to large steel companies, including turnkey solutions and options for waste recovery. It expanded from a highly competitive local cluster into export markets by industrializing its organization and focusing on reliable, fast deliveries. "We are able to offer a complete service and fast delivery," says Riccardo Ambrosini, Operations Manager. - The challenge

A very broad range meant extreme customization, frequent product changes and long order lead times. The sheet metal workflow relied on separate machines and dedicated specialists, becoming complex and resource-intensive and absorbing five to six people. CO.IM.A. needed a single, continuous flow from laser cutting to bending, without being locked into rigid systems with minimum-quantity constraints. "We knew we had to move toward a single, continuous flow, from laser cutting to bending," says Ambrosini. - The solution

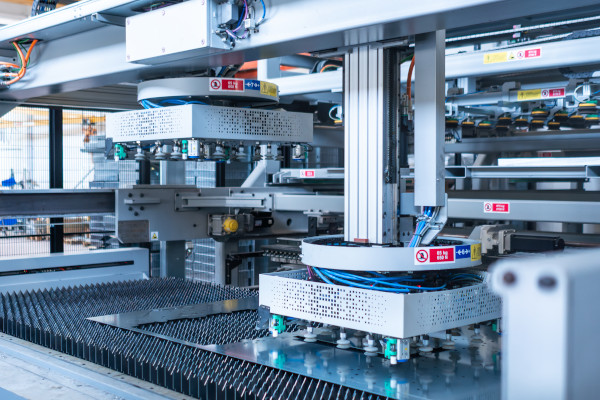

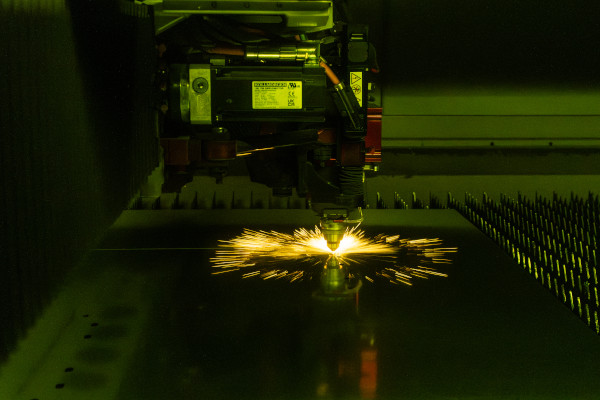

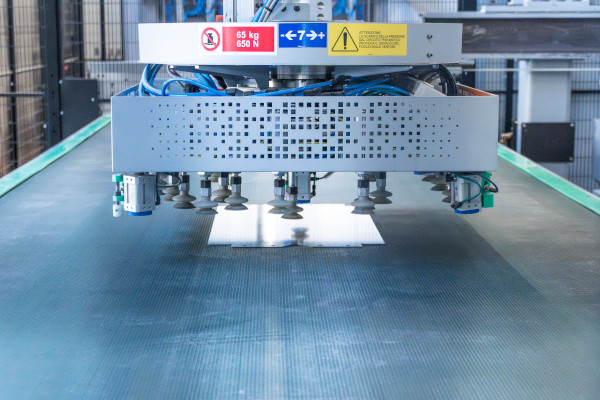

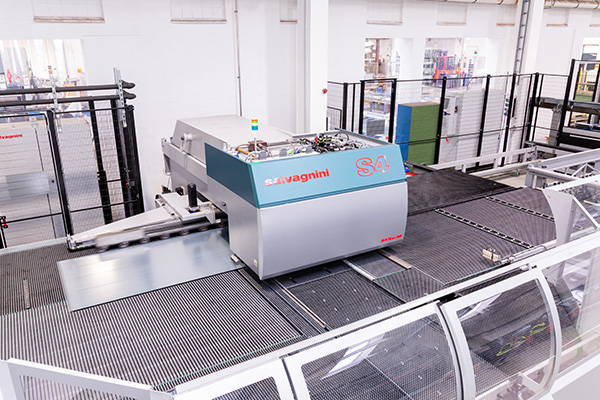

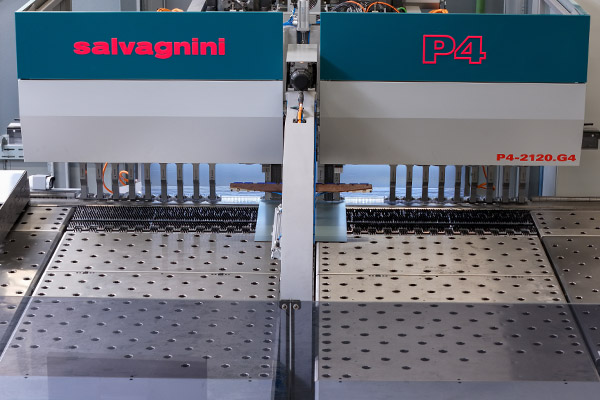

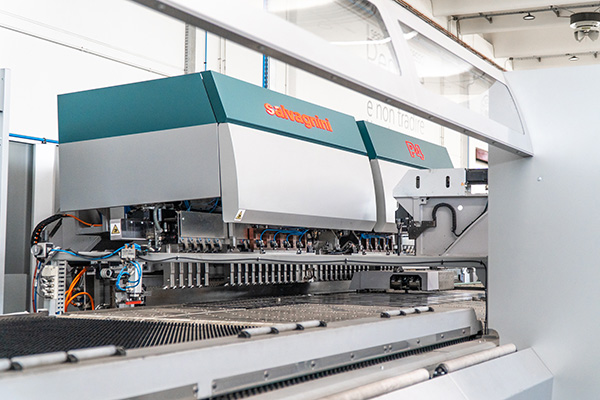

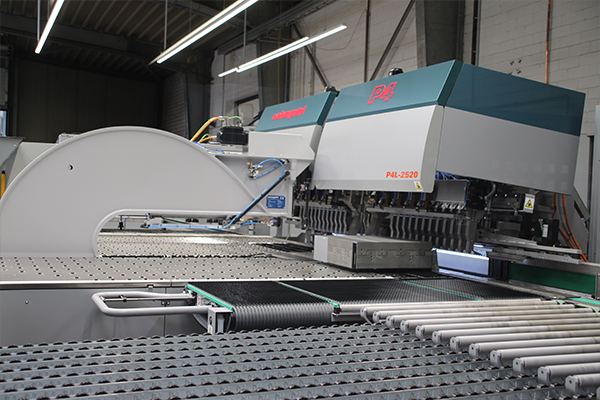

CO.IM.A. implemented a Salvagnini flexible manufacturing system (FMS) built around an L5 laser cutting system with an LTWS store-tower and an MCU automatic sorting device, feeding a P4 panel bender and supported by a B3 press brake. MCU routes parts to P4 or stacks them in an unloading bay, with a customized layout to overcome reduced footprint constraints. Although not physically connected, the B3 is integrated into the flow via P-PB-CXN, which automatically loads the B3 program at the end of the panel-bending cycle. - The results

Fast changeover on the P4 enabled CO.IM.A.’s shift to modular, kit-based production, supplying parts in the correct assembly sequence to speed up on-site installation of very large systems and streamline documents such as the packing list. Automated program transfer to B3 via P-PB-CXN increased productivity and reduced the risk of errors. With the interconnected software suite, programming moved to the technical office and the company progressed to a complete production-cycle logic, achieving Industry 4.0 certification.