Case study

Henke: once again Salvagnini, once again automation!

After the positive experience with the Salvagnini S4+P4 line punches purchased in 2020 (you can learn more here), Henke didn't think twice about investing in a B3 press brake when in 2022 the bending department was the bottleneck. Then in September 2023, in order not to lose sight of automation, a ROBOformER robotic bending cell equipped with a B3.AU-TO press brake was introduced.

Highlights

- Henke

Henke GmbH is a specialist in industrial sheet metal processing from Altenstadt, Germany, equipped with the most modern fiber laser cutting systems, punching machines, press brakes, and panel benders. With approximately 125 employees, it processes more than 5000t of sheet metal per year. - The context

Having gradually moved away from stand-alone machines since 2015, in 2020 Henke decided to invest in a fully automated Salvagnini S4+P4 punching-bending line to support growing production volumes. The S4+P4 system punches, shears and bends sheet metal parts from standard blanks without any intermediate handling of the semi-finished parts. It is precisely thanks to this system that Henke can offer its products at a price 30% lower than before. In 2022 however, the bottleneck was the bending department. After the positive experience with the Salvagnini punching-bending line, Jens Wolf, CEO at Henke, contacted Till-Christian Salm, head of Salvagnini sales in southwestern Germany, again. - The project

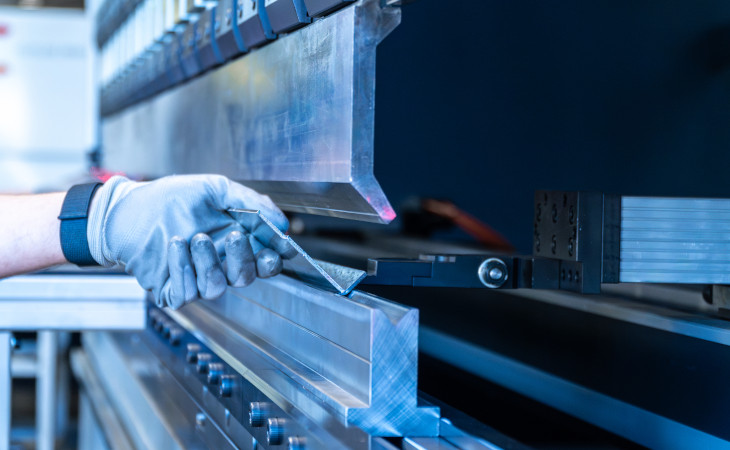

"The fast delivery time convinced me”, says Wolf. After not even six weeks, a B3 press brake with 135 tons of bending force and a bending length up to 3000 millimeters moved into the hall. The press brake is equipped with an automatic upper and lower tool adjuster for Wila tools and therefore can be used universally also with Henke's current tool inventory. The B3 has a direct drive that combines the advantages of electrical and hydraulic press brakes. At the beginning of September 2023, another machine from Salvagnini started up in Altenstadt: the robotized bending cell ROBOformER featuring the B3.AU-TO press brake, an automated cell with automatic retooling and a tool store.