Case study

Boosting production capacity with flexible automation

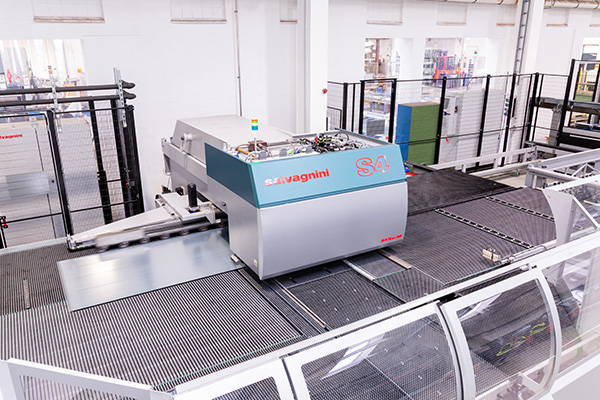

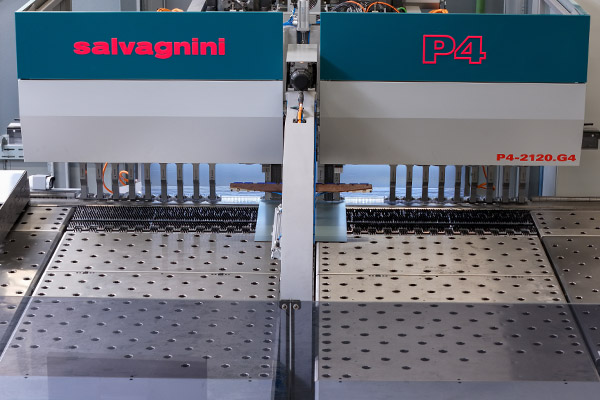

Hörmann Changshu Door Production Co., Ltd. broke through capacity bottlenecks by building a highly automated, high-mix sheet-metal flow around a Salvagnini S4+P4 FMS line with a double MD store tower. The line enables batch-one and kit production with rapid changeovers and fewer manual steps.

Boosting production capacity with flexible automation

Highlights

- Hörmann Changshu

Hörmann Changshu Door Production Co., Ltd. is Hörmann Group’s third plant in China, part of a global door manufacturer founded in 1935 with over 40 factories worldwide. The site is primarily engaged in the production of interior doors, residential doors, entrance doors, tubular doors, and various types of partition walls. "In China, time is crucial," says Mario Bock, Plant Director. - The challenge

Hörmann’s reliance on traditional equipment drove capacity constraints, especially in 2016 and 2017, when a surge in order intake created a production bottleneck. Manual, skill-dependent operations required high manpower and impacted efficiency, while non-flexible machines limited rapid changeovers, making batch-one and kit production hard to execute as demand shifted. - The solution

Hörmann equipped Changshu plant with a Salvagnini S4+P4 line and a double MD store-tower to run punching, shearing and panel bending in a single automated flow, avoiding intermediate handling. - The results

The S4+P4 line with MD store tower reduced labor and eliminated intermediate handling, improving efficiency while enabling changeovers for batch-one and kit production. "We still have free capacity. We can easily double output with a little bit more investment and a little bit more upgrades," says Mr. Bock.

Check out the case study

Hear what Mario Bock, Plant Director at Hörmann Changshu, says about this project.