Case study

The right solution even for batch-one production

Story courtesy of G. Maier/BLECH

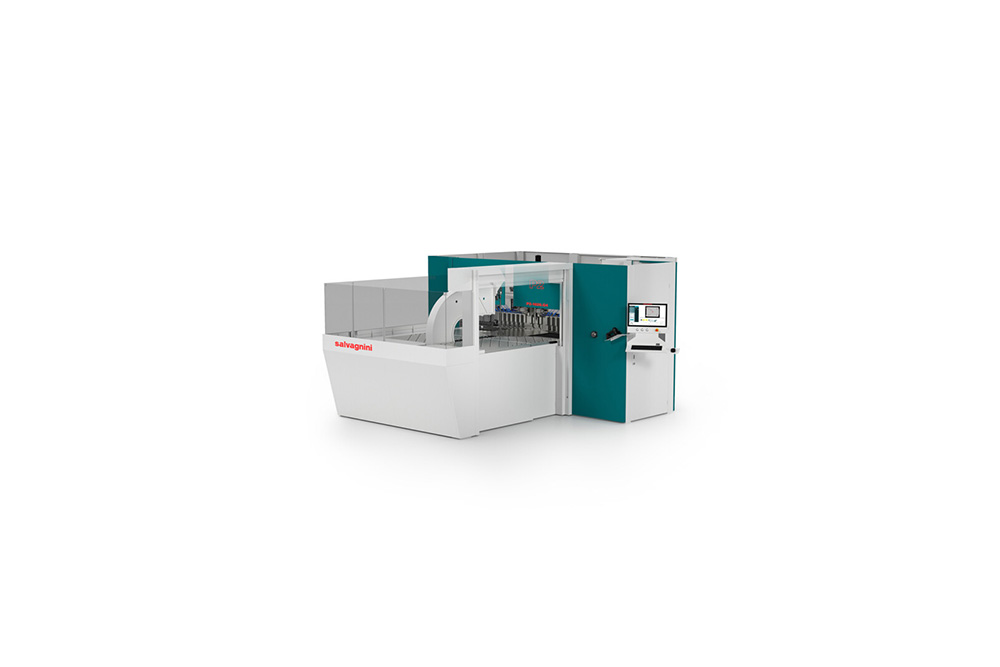

Salvagnini’s panel bender range is often associated with the cost-effective production of large quantities. The specialists for food cooling and heating solutions at WIHA know the advantages of using a P2 panel bender, even for batch-one production.

The right solution even for batch-one production

Highlights

- WIHA

Based in Lower Saxony, Hakemann GmbH & Co. KG, the proprietor of the WIHA brand, is a third-generation family business serving leading shopfitters for airports and malls. Across 14 production halls (~13,000 m²) and ~90 people, it builds ~5,000 food cooling/heating devices annually, backed by 40+ patents that blend craftsmanship with modern technology. - The challenge

Batch-one and small-lot production without stock requires fast changeovers, minimal scrap, and repeatable quality while controlling delivery times in-house. “There are around 1000 different products or configurations in our catalog. This requires a great flexibility on our part,” says Gilbert Renschen, Technical Operations Planning. - The solution

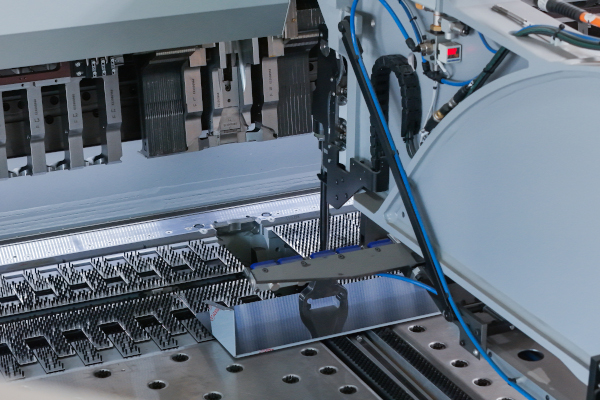

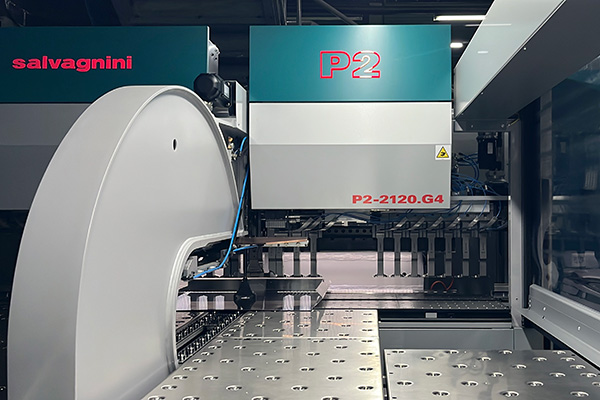

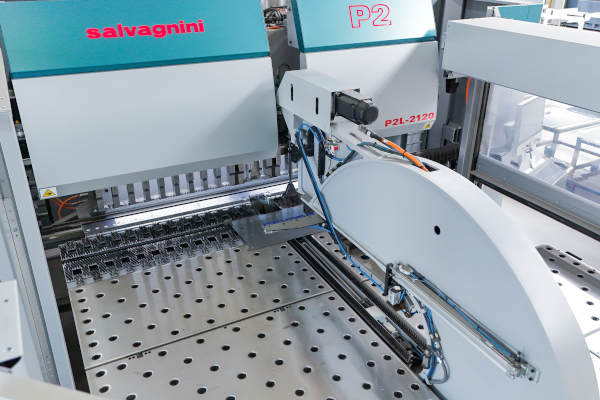

Since 2023, WIHA has been running a Salvagnini P2-2120 equipped with the DPR data part reader. In practice, the operator simply places the blank on the work area; from there, the manipulator takes over, automatically gripping, aligning, rotating and sequencing each bend. The upper and lower blades work with the counterblade and automatic blankholder to form edges in a smooth, repeatable flow. Integrated sensors, together with Salvagnini’s bending formula, read thickness and material behaviour in real time and tune bending force and trajectories to the part. For positive bends up to 1,060 mm, CLA auxiliary blades extend capability, while the RSU tool scores for tight radii and crisp box edges. - The results

WIHA reports well over 50% time savings from reduced set-ups, a sharp drop in errors, and lighter operator workload. “What is particularly impressive are the precise box sizes, reliably maintained to within a hundredth of a millimeter,” says Gilbert Renschen. The P2 proves the perfect solution for make-to-order, handling batch-one and small lots with stable quality, predictable lead times, and smooth production flow.

Check out the case study

Hear what Gilbert Renschen, Technical Operations Planning at WIHA, says about this project.