Case study

The added value of 2D cutting

Story courtesy of E. Oldrati/Deformazione

From mathematics to end product. This is the production strategy of Lasergate, the company based in Carmagnola (Turin, Italy) specialized in prototyping and low-volume production for a range of sectors, including the luxury car industry. Pursuing a business vision focused on the continuous innovation of production technologies, the company has invested in a Salvagnini L5 2D laser cutting machine, aiming to optimize its machining cycles.

The added value of 2D cutting

Highlights

- Lasergate

Lasergate is a Carmagnola (Turin, Italy) sheet-metal specialist founded in 2001, born in 3D laser cutting and grown into an end-to-end partner: mold making, forming, bending, manual/robotic welding, metrology, tooling and assembly, mostly in-house. With four sites, ~90 employees and ~€12M turnover, it serves high-end automotive and other sectors with prototyping and low-volume, repeatable batches. - The challenge

Lasergate manages a variable mix of materials, thicknesses and SKUs while meeting production repeatability. Precision cut items drive downstream forming, 3D laser cutting, bending and welding. Accuracy is critical: "Five minutes out per sheet, multiplied by two hundred sheets, changes the Monday morning scenario by eight hours," says Davide Spezini, Co-founder. - The project

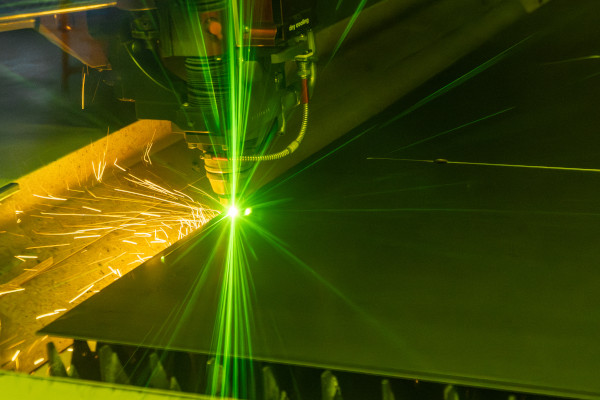

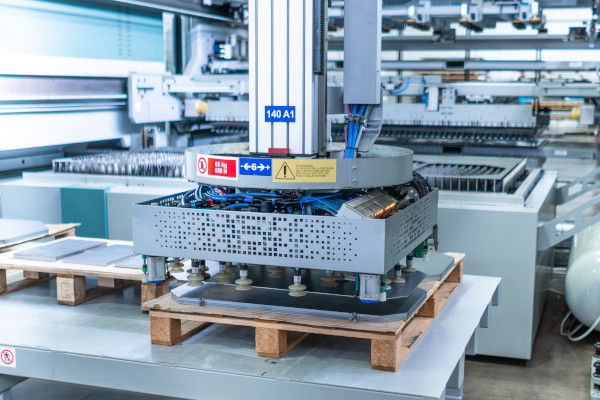

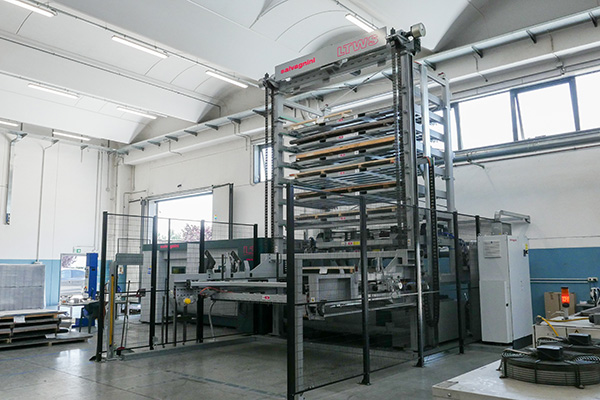

Lasergate installed a 6 kW Salvagnini L5 2D laser with an LTWS store-tower for unmanned loading/unloading and an MCU sorting system. The MCU grip surface is segmented into independent quadrants. With Nexus, it can run multi-gripping and double-picking. The system cuts 0.5–5 mm sheets, mainly aluminum, mostly in nitrogen, plus compressed air on thin gauges. - The results

The L5 cell boosts stability and production continuity as volumes shift from prototyping to production. LTWS tray flexibility and MCU sorting reduce handling of aesthetic and thin parts, protecting finish quality and supporting part traceability. Salvagnini’s service, proactive support and remote diagnostics increase uptime and reduce risk, improving cost predictability and total cost of ownership defensibility.