Guido Salvagnini founds the company

The company that is now Salvagnini was founded in 1963 in Quarto Oggiaro to specialize in the design and manufacture of lubrication units. In 1970, the company moved to Bresso, near the airport. In 1974 , it moved its headquarters to Sarego, where Salvagnini Italia still is today.

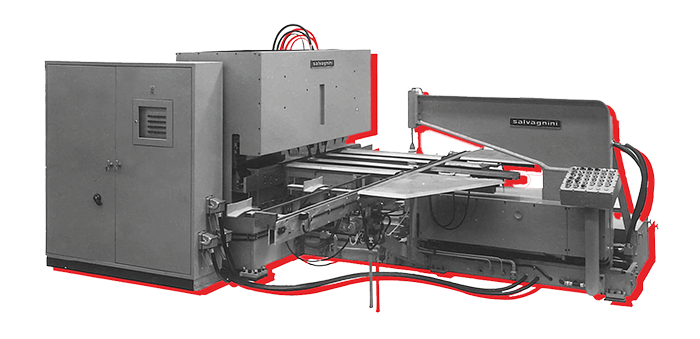

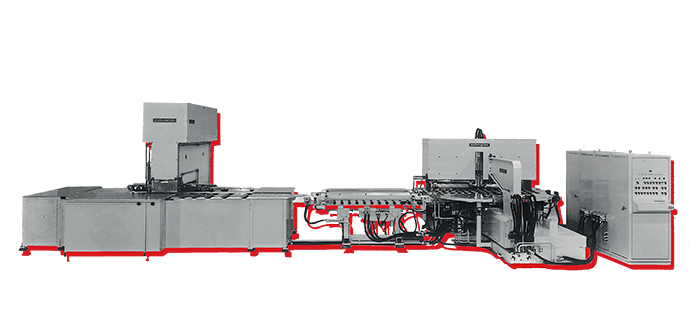

The invention of the panel bender

We designed the first panel bender and we named it P4. Since 1977 the panel bender has never stopped evolving: today it is a solution with proven reliability, an automatic machine in all aspects and ideal for a modern smart factory.

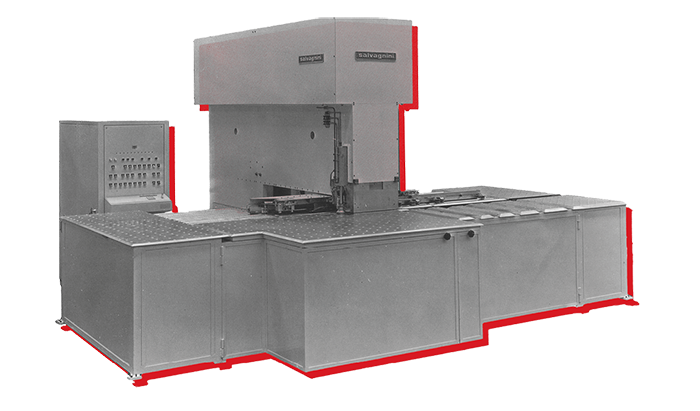

Notching on four angles

The S4 is the world-famous combined punching-shearing center, a legendary machine that has continued to evolve since 1978 and, now as then, guarantees maximum precision, minimum waste, and high efficiency.

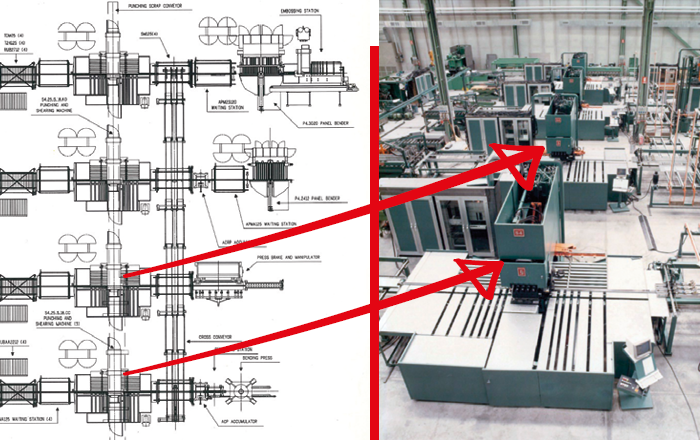

The first FMS

Combining the S4 punching-shearing machine and the P4 panel bender results in the first flexible manufacturing system ever built. The S4+P4 line was a milestone in the development of integrated logistics systems. It is still the most efficient FMS on the market today.

Lights-out manufacturing

Made of multiple S4+P4 lines combined together, working overnight unmanned, the fully automated factory designed and built for General Electric in 1985 was completely autonomous in scrap optimization, production, and also in restart after a power blackout. After 27 years of production, the first automatic factory in history has been definitively discontinued in 2012.

OPS: proprietary process software

Salvagnini soon realized the importance of industrial connectivity and technological integration. When the first Order Processing System, the modular production management software known as OPS, was put on the market Industry 4.0 was a reality: it was 1993. OPS schedules, balances, and optimizes factory production flows automatically according to production strategy.

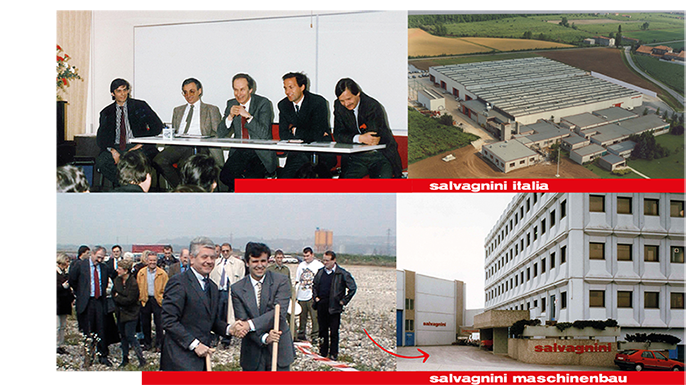

Salvagnini Group is taking shape

Salvagnini Italia Spa and Salvagnini Maschinenbau GmbH are established in Sarego and Linz.

The ROBOformER

The ROBOformER is a totally automatic press-brake cell, run by a controller and a single program. It was born from software, which programmed the cell with the same logic of the P4 panel bender. Integrating a press brake, a robot, and a number of devices for automatic sheet metal handling was a complex challenge, but today ROBOformER allows unmanned production while guaranteeing all the benefits of robotic bending: repeatability, flexibility, versatility.

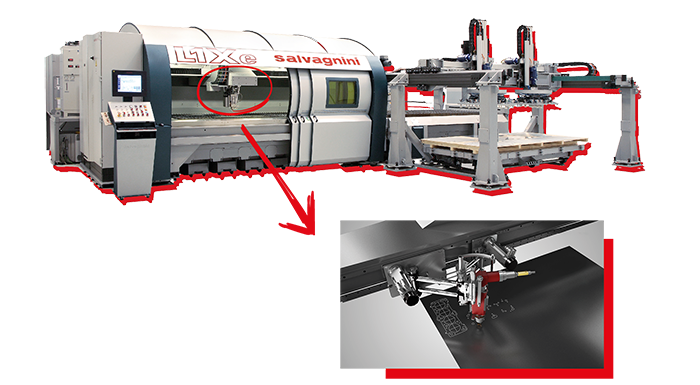

Fiber in laser cutting

Between 2007 and 2008, we began investigating the potential of fiber laser technology in cutting sheet metal. The first L1Xe laser system came from these researches: it was the first fiber source laser to be made available on the market. Many technical features of this early solution, such as the airplane structure, the rapid pallet change, and the automated loading/unloading and sorting devices, are still relevant today.

The S1 punch-laser combi machine

Reinventing the concept of the punch-laser combi machine while maintaining classic Salvagnini concepts such as the multi-press head, hybrid drive and flexible automation led to the design of the S1, a truly unique and innovative system.

Salvagnini Campuses

Training, education, research, people, collaboration, and the future: Salvagnini Campuses, the technological centers open to visitors, are this and a lot more.

Salvagnini Campus - Italy (top picture)

Salvagnini Campus - America (bottom picture)