Punching machines

S1 is a punch-laser combi machine, a true work center that punches, forms, taps, and cuts parts.

Learn more

Press brakes

The B3 was designed by combining the features and benefits of electric and hydraulic press brakes with Salvagnini’s in-depth knowledge of automation, software, mechanics and electronics.

Learn more

Punching machines

S4Xe is the world-famous combined punching-shearing center, a legendary machine that has continued to evolve since 1978 and, now as then, guarantees maximum precision, minimum waste, and high efficiency.

Learn more

Punching machines

Introducing the Salvagnini S4: a hybrid punching-shearing machine offering unmatched productivity, efficiency, and flexibility.

Learn more

Panel benders

The PX natively combines productivity, with its automatic bending cycles, with flexibility, using universal bending tools. For uncompromising performance.

Learn more

Laser systems

The L3 is a versatile, multi-purpose laser designed for transversal use, whatever the applications, materials and thicknesses.

Learn more

Laser systems

The L3.G4 is Salvagnini's high-performance and versatile fiber laser cutting machine. It is designed to improve ergonomics, guaranteeing maximum precision.

Learn more

Laser systems

The L5 is a particularly high-performing laser with high dynamics on thin and medium-thin thicknesses.

Learn more

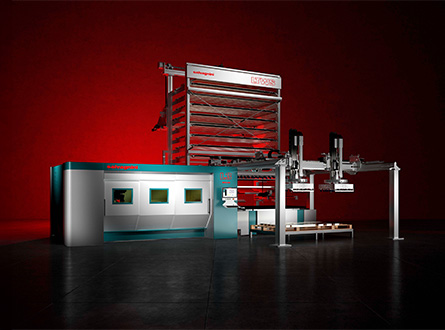

FMS systems

Simply the line. Since 1979, it is the most efficient flexible manufacturing system on the market for sheet metal processing.

Learn more

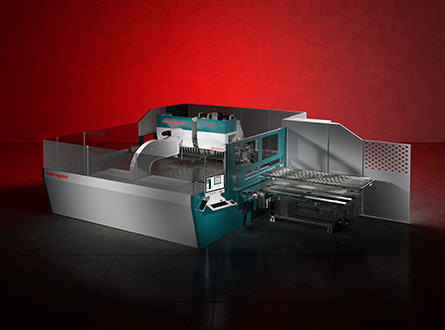

Panel benders

The P2 seduces with its high technological content, low energy consumption and compact layout, without forgetting the productivity and flexibility typical of Salvagnini panel benders.

Learn more

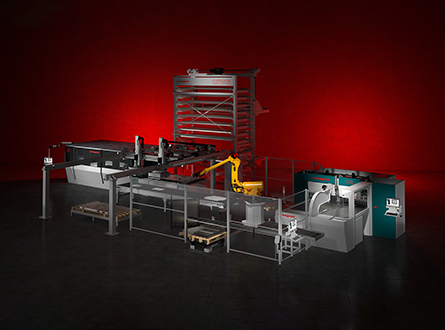

FMS systems

The Flexible Smart Job Shop (FSJ) is a combination of advanced technologies, software, artificial intelligence and vision (AI), robotic and automation solutions for dynamically facing the challenges of the modern market.

Learn more

Panel benders

The P4 amazes with its configuration potential and performance: productive and flexible, it can be independent, work in a flexible cell or be installed in an automatic factory.

Learn more

Panel benders

Streamline your panel bending operations with P-Robot, a robotic bending solution that adapts to varying production demands and enhances productivity.

Learn more