Laser cutting systems

High-performance fiber lasers for precise, cost-efficient sheet-metal cutting

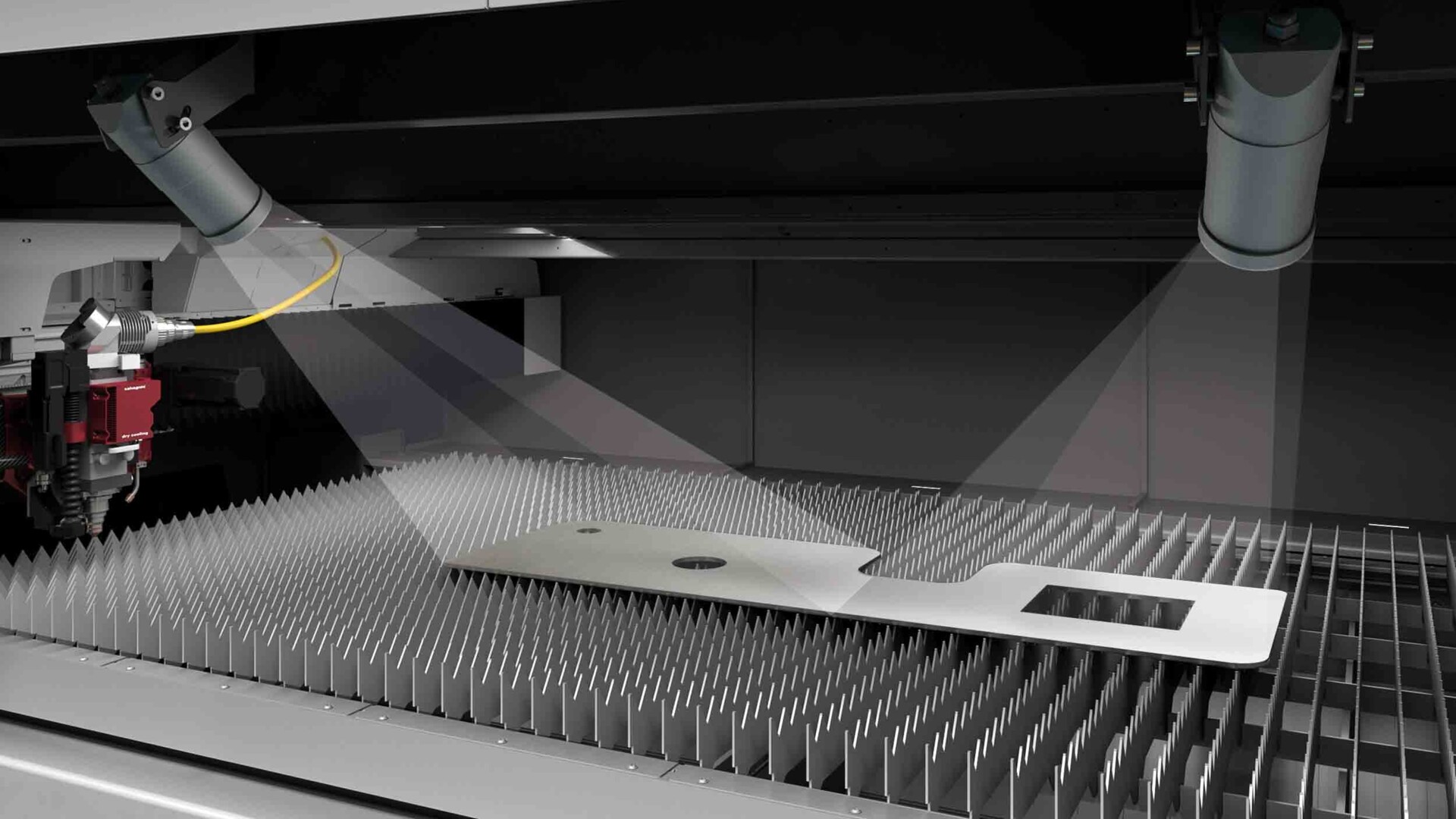

Salvagnini fiber laser cutting machines L3, L3.G4, and L5 combine speed, accuracy and ease of use to optimize cutting across mixed materials and thicknesses. These systems combine intelligent process control and laser cutting automation to deliver consistent quality and a low cost per part on fiber laser cutting while reducing operator intervention. Native nitrogen/oxygen cutting is broadened by the ACUT option, a solution that enables compressed-air cutting with productivity similar to nitrogen but significantly lower assist-gas cost. Each metal laser cutter is available with different source powers that unlock performance typically associated with higher-power lasers, supporting lower energy use and a reduced cost per part across a wide range of materials and thicknesses.

From smart cutting to full laser cutting automation

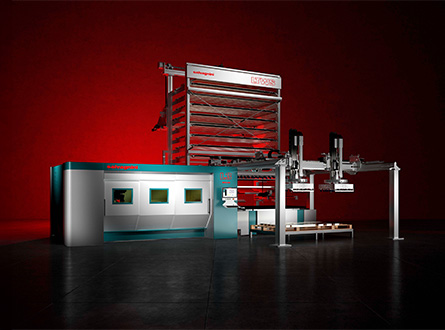

Salvagnini’s sheet metal laser cutting systems scale from stand-alone metal laser cutters to fully automated laser cutting machines with modular automation for loading, unloading and part sorting. Options include CPE pallet changer, ADC/ADLU/ADLL destackers, and the LTWS automated store-tower, which supports just-in-time material availability and ultra-fast changeovers. Sorting is a key strength: the TN manual sorting device lets operators separate parts from skeleton in parallel; the MCU automatic sorting device stacks parts of different sizes and weights using standard, multi-gripping or double-picking strategies. Salvagnini fiber lasers are open to downstream processes, enabling seamless integration with panel benders and press brakes to streamline the end-to-end flow from cutting through bending in automated sheet-metal production. Together, these capabilities raise uptime, shrink changeovers, and maximize ROI for modern sheet metal laser cutting automation.

Product range

The L3 is a versatile, multi-purpose laser designed for transversal use, whatever the applications, materials and thicknesses.

Learn more

The L3.G4 is Salvagnini's high-performance and versatile fiber laser cutting machine. It is designed to improve ergonomics, guaranteeing maximum precision.

Learn more

The L5 is a particularly high-performing laser with high dynamics on thin and medium-thin thicknesses.

Learn more

The result of extensive experience in the field

Salvagnini was one of the first companies in the world to invest in fiber technology. Salvagnini laser comes from this long-standing tradition: it is a versatile, productive solution, with reduced consumption and competitive running costs, that respects the environment, humans and their work.

Modular, scalable automation for regaining efficiency

In the laser world, automation is playing an increasingly key role. Salvagnini loading/unloading and sorting connections satisfy all automation requirements: from stand-alone operation, to integration in flexible cells or in automatic lights-out factories.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the laser system. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Do you have any questions?