Case study

From metal bashing to smart manufacturing

With a unique global footprint, strong product culture and a no-nonsense approach to production, Penn Elcom has grown into a manufacturing leader in 19” racking systems, flight case hardware and specialist enclosures. But behind the scenes, a quiet revolution has been reshaping its UK factory floor, now driven by Salvagnini’s automated bending technologies.

From metal bashing to smart manufacturing

Highlights

- Penn Elcom

Founded in 1974 in the UK, Penn Elcom is a global manufacturer of flight-case hardware, 19-inch racking, crating components, speaker hardware and custom metalwork for the AV, touring, broadcast and IT sectors. It runs manufacturing and distribution in 10+ countries across three continents—including hubs in Hastings (UK), the USA, Germany, Australia and China—and offers a catalogue of 6,000+ products. “I used to think of us as metal bashers,” says Roger Willems, Chairman. - The challenge

Bending was the bottleneck. Managing tool changes, operator variability and long set-ups meant 14 press brakes still couldn’t meet demand. Skills were scarce and lead times shrinking: “We knew we had to reduce manual handling, improve consistency, and increase throughput,” notes Rafal Parda, Managing Director. - The solution

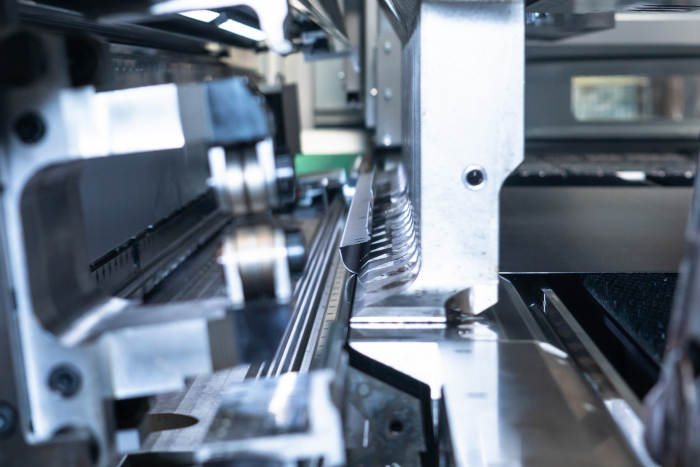

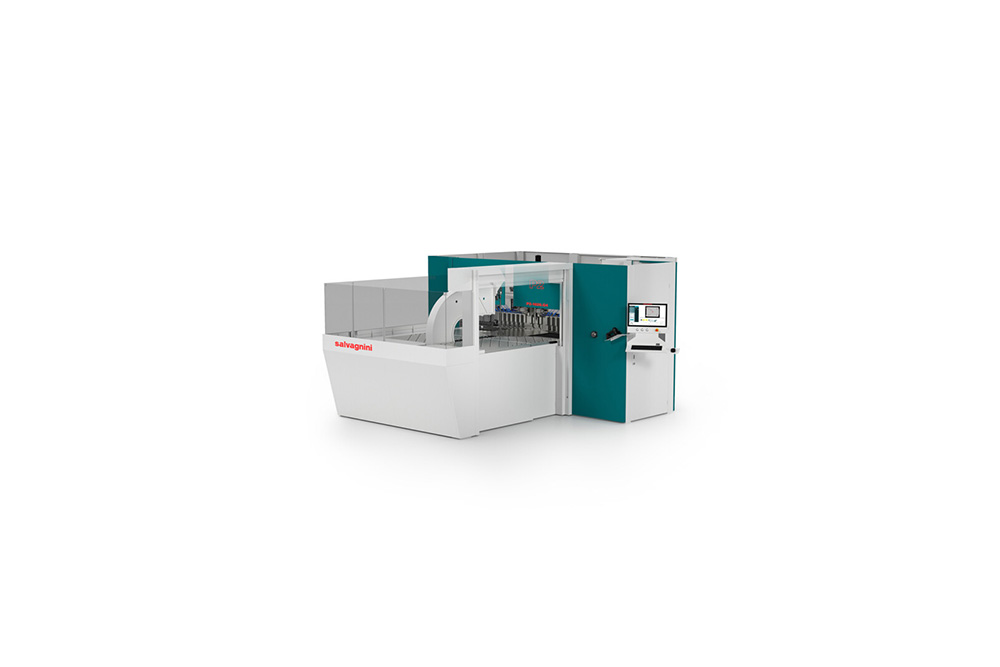

Over the years, Penn Elcom has installed two P4 panel benders with automatic ABA blankholder and universal tools, a compact P1 for smaller parts, and a B3 press brake with ATA Automatic Tool Adjuster. In 2025, the company expanded its capacity with a P-Robot cell combining a second P1 with a robot and roller conveyor. STREAM and OPS connect programming with the ERP system, enabling real-time production flow. - The results

Lead times were slashed; stock moved from backorder to same-day availability. Capacity doubled without extra operators. Assembly headcount fell from 11 to 4 while weekly output rose beyond 20,000 parts. Degauging from 1.2 mm to 0.7 mm cut material and freight costs. “Do the maths: these machinee paid for themselves in setup time alone,” adds Parda.