Case study

Investing in technology to remain competitive

Story courtesy of E. Oldrati/Deformazione

Forward-looking investments and skilled personnel are behind the Tecnofreddo international success, a Sicilian company specialized in the design and construction of refrigeration systems. Increased flexibility and quality thanks to machines such as the recent B3 press brake supplied by Salvagnini.

Investing in technology to remain competitive

Highlights

- Tecnofreddo

Tecnofreddo is a Sicilian manufacturer based in Marsala, designing and building refrigeration systems for industrial process and air-conditioning applications. With about 50 employees, it closed 2024 at ~€11M turnover and targets ~€15M in 2025, selling 60% in Italy and 40% abroad. - The challenge

Competing from Sicily against northern Italian and European players meant relying less on subcontractors and more on repeatable processes. With a limited local sheet-metal supply chain, Tecnofreddo chose to bring key sheet-metal operations in-house to protect lead times, quality and the flexibility required by highly engineered, one-off projects. - The solution

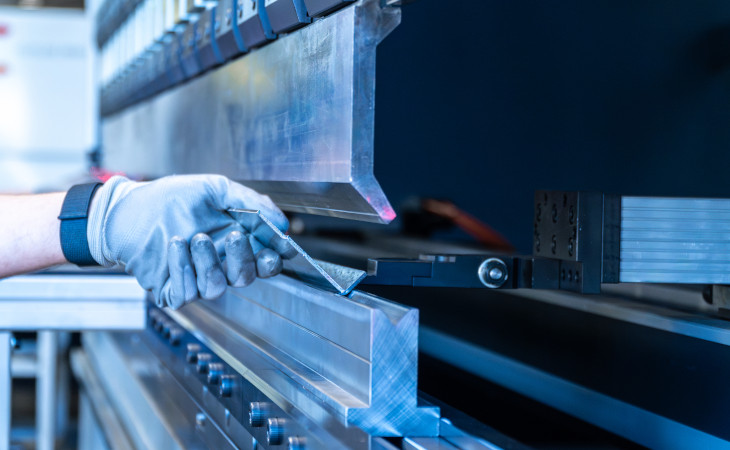

The 2024 investment replaced an existing press brake with a Salvagnini B3 press brake. The B3 delivers 4,250 mm max bending length and 240 t force, with BG7 backgauge. It features adaptive technologies S-CROWNING and TFC2, it is monitored via LINKS IoT, and processes Z200/Z300 galvanized sheet 1–6 mm for ~10,000 bends/month. - The results

"We are very satisfied about our investment in the Salvagnini press brake," says Osvaldo Asaro, owner of Tecnofreddo, "because we were able to consolidate our strategy that is focused on a market where there is less competition: here we offer our customized refrigeration systems to satisfy the needs of companies that require significant technical development."