Case study

Productive integration elevates vertical mobility

Story courtesy of A. Ariu and G. Mazzola/Lamiera

KONE innovates the production of elevators in Italy thanks to the adoption of performing Salvagnini technologies. A historical synergy that optimizes operating flows and reduces processing times for the production of cabins and doors.

Productive integration elevates vertical mobility

Highlights

- KONE

KONE Industrial manufactures elevator cabins and landing doors for global markets. Production is highly configurable and make-to-order, managing numerous dimensional options and finishes across thin-gauge sheet (typically 0.8–1.5 mm), with dedicated lines for doors and cabins governed by centralized, flexible staffing. - The challenge

High product variability and strict quality standards demanded faster throughput, fewer intermediate buffers, and tighter control of WIP. The goal: increase OEE, reduce manual handling and storage moves, and maintain traceability while sustaining intense, continuous production cycles across hundreds of part variants and options. - The solution

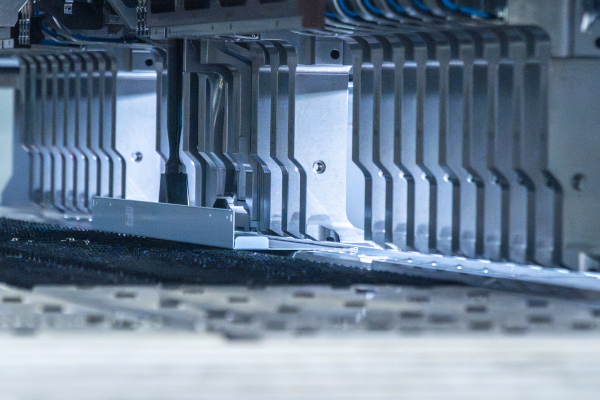

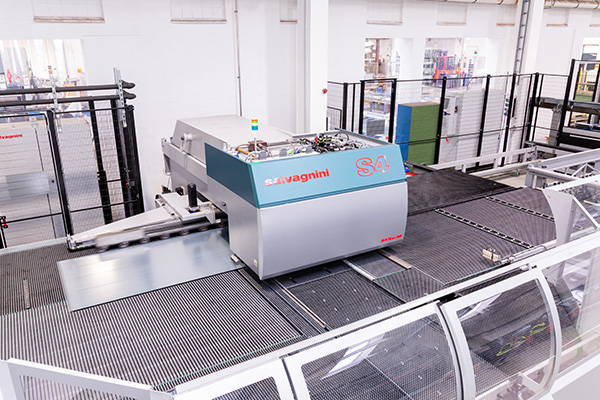

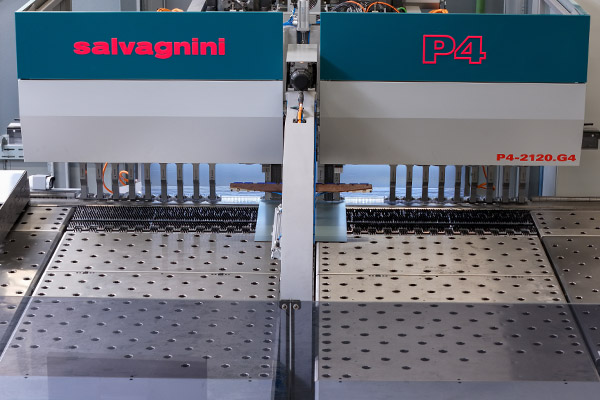

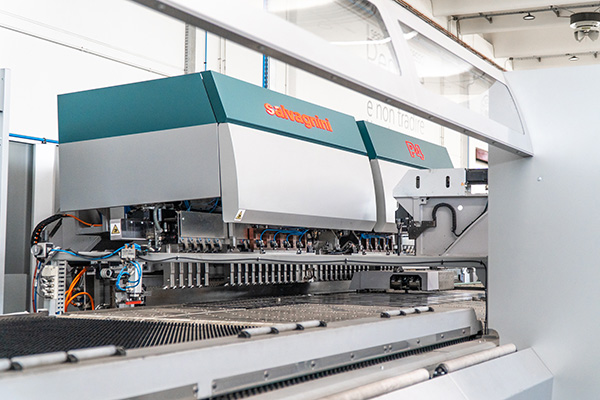

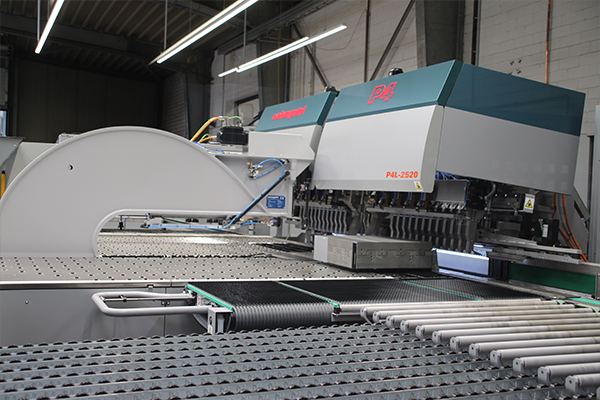

A new S4+P4 FMS, fed by a single-sheet MD store-tower, slots into the existing layout alongside the pre-existing lines. The flow is lean and connected: the MD supplies the S4; parts to be bent move to the P4 for panel bending and then feed directly to the B3 press brake via P4→B3 software integration, with no intermediate buffer stops. This ensures in-process traceability, automatic priority re-sequencing, and operational continuity, absorbing the variability typical of make-to-order. The outcome is a more coherent production flow with lower WIP and non-value-added time, better operator utilization, and greater predictability in lead time, quality, and production costs. - The results

For some specific components, cycle time drops from about 180 to 60 seconds. With handling and intermediate storage removed, the flow stays continuous: priorities are re-sequenced in software, operators focus on value, and a full shift is absorbed through smarter resource allocation. Selective insourcing lowers unit cost and supports a payback in under two years. “The main advantage is that we can obtain a pre-bent FAT without the need to move it,” says Mauro Mongiardo, PCU Manufacturing Solution Manager.