Case study

Ferrero Automotive: automated logistics solutions for the automotive sector

Story courtesy of A. Ariu and G. Mazzola/Lamiera

To guarantee top quality and competitive performance, Ferrero has increased its efficiency and degree of automation in some processing steps with Salvagnini technologies: from laser cutting, supported by an automated loading/unloading and sorting system, passing through bending.

Automated logistics solutions for the automotive sector

Highlights

- Ferrero Automotive

The Automotive division of Ferrero, based in Casalgrasso (Cuneo, Italy), specializes in the design and production of metal containers with columns, carriages and platforms used for the internal and external industrial handling of materials, semi-finished parts and finished products. These are innovative systems, some of which are patented, with a high technological content, supplied to leading manufacturers and component producers working in the automotive sector. - The context

For quite some time, Ferrero Automotive relied on high-quality metalworks subcontracting that demanded considerable effort for control. Given the rapid growth in both the product portfolio and innovations, eventually outsourcing became too limiting and complex to manage, ultimately impacting the company's competitive performance. - The project

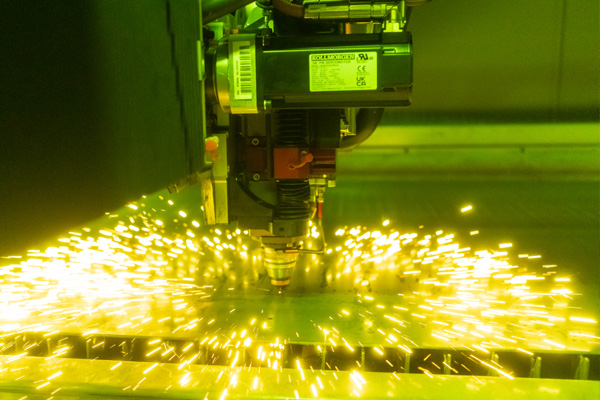

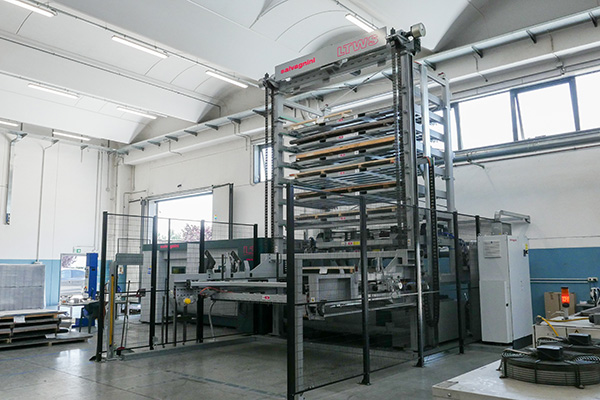

These critical issues convinced Ferrero to internalize the whole production cycle, starting from sheet metal cutting and bending. The investments focused on highly automated technologies. Ferrero purchased a new Salvagnini L3 laser cutting system with fiber technology, to cut sheet metal measuring max. 3048 x 1524 mm, complete with ADLL automatic loading-unloading device and MCU sorting device, in addition to a 170-ton B3 press brake. - The outcome

The integration of Salvagnini process technologies and automation has allowed Ferrero to optimize the product development cycle, reducing production times.