Case study

Smart additional options for maximum flexibility

Story courtesy of G. Maier/BLECH

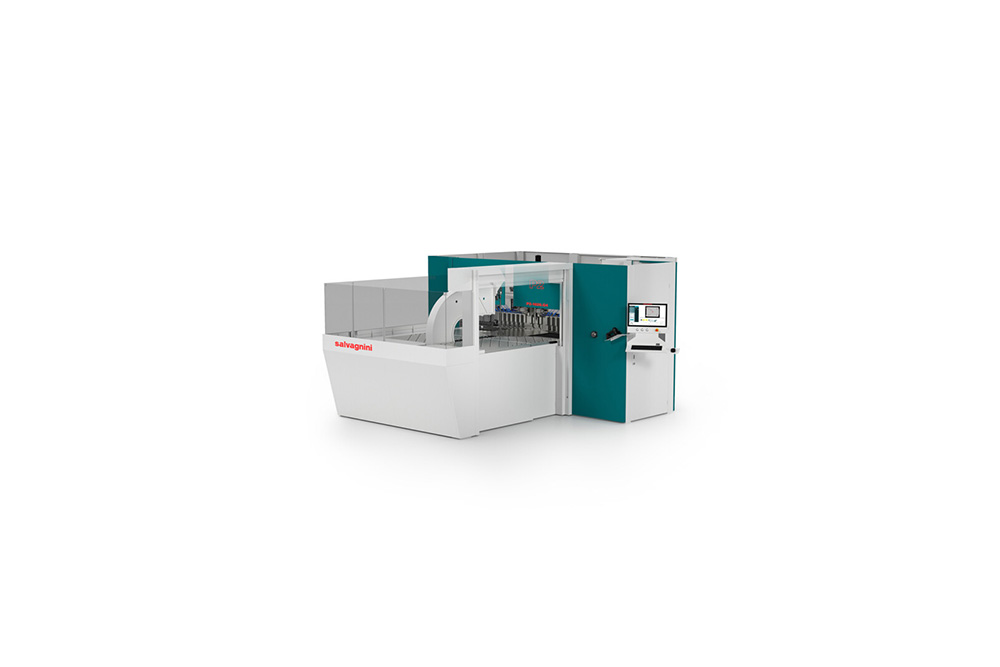

Schickling already had positive experiences with Salvagnini P1 panel bender. But in order to manufacture even more flexibly and further expand its options, the company purchased a new P2 in 2024. Its smart additional options provided Schickling with the flexibility it needed to be future-oriented.

Smart additional options for maximum flexibility

Highlights

- Schickling Maschinenbau

Schickling Maschinenbau GmbH is a family-run metalworking and assembly specialist in Visbek, Germany, serving agricultural, utility-vehicle and industrial OEMs. The company employs around 300 people and also builds the Schickling Grill line, shipping about 14,000 units per year. - The challenge

By 2024, demand across core sectors was booming and hiring remained difficult, pushing utilization to the limit. P1’s 1,250-mm length/127-mm height envelope constrained the part mix. Frequent product changes and visible radii called for more flexibility and consistent quality. - The solution

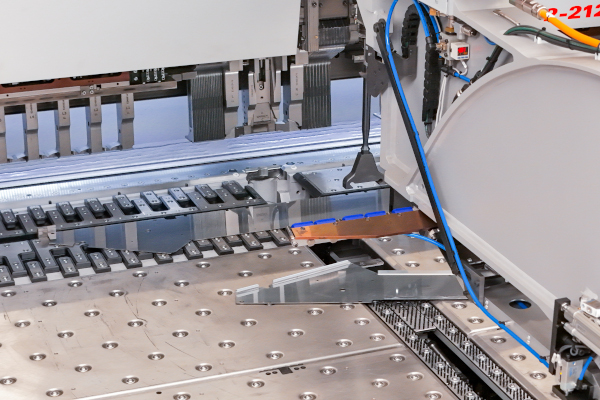

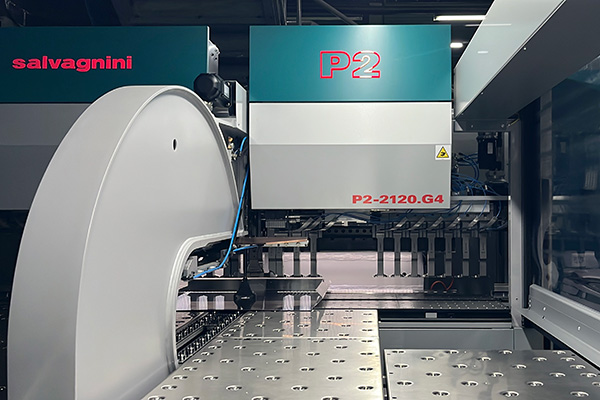

In 2024 Schickling invested in a Salvagnini P2-2120 configured with Option P, DPM for narrow or cut-outs parts, and the CLA auxiliary blade. Capacity: up to 2,180-mm length, 203-mm bending height; 3.2-mm steel, 2.5-mm stainless, 4-mm aluminum; one-time centering and interpolated blade motion. - The results

The P2 expanded the bending window, shifting many parts from press brakes and delivering significant time savings. Both panel benders at Schickling now run at full capacity; P2 output is roughly 50/50 between customer orders and grill parts. “These options were decisive… we increased flexibility and component quality,” says Philipp Schickling, CEO.