Panel benders

Automated panel bending for HMLV and mass production: high performance, every run

Salvagnini panel benders balance productivity and flexibility for both high-mix/low-volume and large-series sheet-metal fabrication. With universal tooling and automatic handling and bending cycles, each machine minimizes setup and operator intervention while ensuring repeatable quality on complex parts and variable materials. Integrated adaptive technologies such as MAC3.0, the proprietary bending formula, and a series of advanced sensors automatically compensate for variations in material and ambient conditions, eliminating waste and rework while keeping processes stable and consistent. From compact panel benders like the PX to fully automatic panel benders such as the P4, the range delivers high throughput and consistent angles with low energy consumption, helping contain operating costs.

Because bends remain consistent over time, downstream automated or robotized operations benefit directly: robotic welding, assembly, and finishing run faster, with fewer fixtures, less touch-up, and more stable cycle times. The result is a genuinely attractive total cost of ownership: lower energy and consumables, less changeover time, and a reduced cost-per-bend across both high-mix/low-volume and large-series production.

From smart panel bending to fully connected manufacturing

Every Salvagnini panel bender, regardless of model or automation level, operates as part of an intelligent production environment. Stand-alone automatic bending machines can be natively integrated via software with upstream and downstream work centers, exchanging real-time information and feedback with the factory ERP/MRP. In connected layouts, the same panel benders fit naturally into FSJ cells and S4+P4 FSL lines, supporting lights-out flows and minimizing through-times and WIP in a JIT logic that helps reduce inventories and improve cash flow. Industry 4.0 connectivity keeps workflows synchronized from batch-one to mass production, while options such as P-Robot extend automation for loading, handling, and bending across PX, P2, and P4 systems, scaling utilization without creating bottlenecks.

Product range

The PX natively combines productivity, with its automatic bending cycles, with flexibility, using universal bending tools. For uncompromising performance.

Learn more

The P2 seduces with its high technological content, low energy consumption and compact layout, without forgetting the productivity and flexibility typical of Salvagnini panel benders.

Learn more

The P4 amazes with its configuration potential and performance: productive and flexible, it can be independent, work in a flexible cell or be installed in an automatic factory.

Learn more

Streamline your panel bending operations with P-Robot, a robotic bending solution that adapts to varying production demands and enhances productivity.

Learn moreHow does a panel bender work?

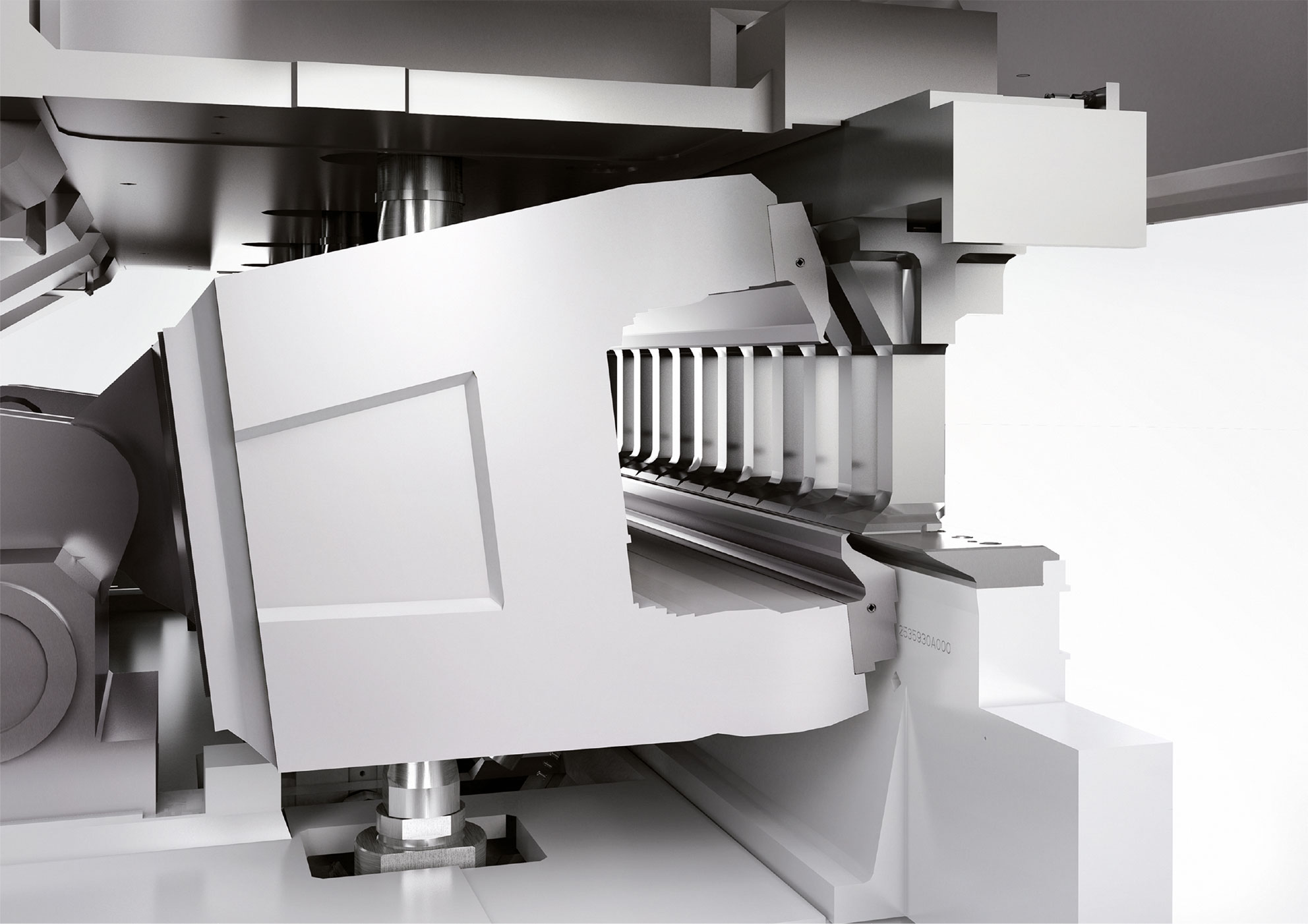

The upper and lower blades are the two tools featuring interpolated controlled movement and responsible for bending.

The automatic blankholder works simultaneously with the blades and counterblade to bend and clamp the sheet accurately and effectively. It adapts the tool length according to the size of the part being produced during the cycle, without machine down times or manual re-tooling. The tool profile allows inward bends up to 45 mm.

The counterblade helps clamp the sheet during the cycle.

The upper and lower blades are the two tools featuring interpolated controlled movement and responsible for bending.

Operating mode: simple, quick and lean

Bending on each side of the sheet is achieved thanks to the controlled interpolated movements of the blades.

Flexible automation

Upper and lower blade, counterblade and blankholder are the four universal tools used to process the whole range of thicknesses and machinable materials, from 0.4 to 3.2 mm, during the cycle and without machine down times or manual re-tooling.

Proprietary bending formula

Developed over the years, the bending formula defines the force and manages the movements of the universal tools, analyzing different parameters in real time, including deflections, temperature and thickness, guaranteeing the precision, repeatability and quality of the finished product.

Automatic manipulator: fast and accurate

Quickly and fully automatically, this moves, handles, grips and rotates the sheet metal throughout the whole machining cycle. It requires no manual interventions during the cycle. The operator positions the sheet metal on the worktable and collects the product after bending, performing only the loading and unloading operations.

MAC3.0

MAC3.0 detects any differences in the mechanical characteristics of the material compared to their nominal value during the cycle, adapting the movements of the bending unit and the manipulator to compensate them.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the panel bender. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Do you have any questions?