Case study

Hargassner: panel bender for higher output

Story and pictures courtesy of N. Novotny/Blechtechnik

Optimized parts logistics and just-in-time production require cutting-edge manufacturing technology. From sheet metal processing to assembly, Hargassner’s facility in Weng, Upper Austria, is an impressive example of fully automated manufacturing for the heating industry. Recently, an automated Salvagnini panel bender has also been fully integrated in the production flow, contributing to further increase the company's flexibility, process reliability and productivity.

Panel bender for higher output

Highlights

- Hargassner

Hargassner Ges mbH is one of the global players in sustainable and CO2-neutral biomass heating systems. The competence in the field of wood heating technology at the Weng site is now backed by around 750 employees, who have set the highest standards for modern pellet, wood chip and wood heating systems with innovative technology in terms of combustion, control and mechanics. - The project

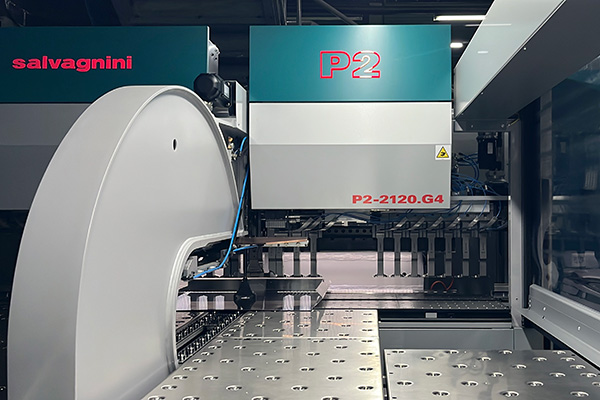

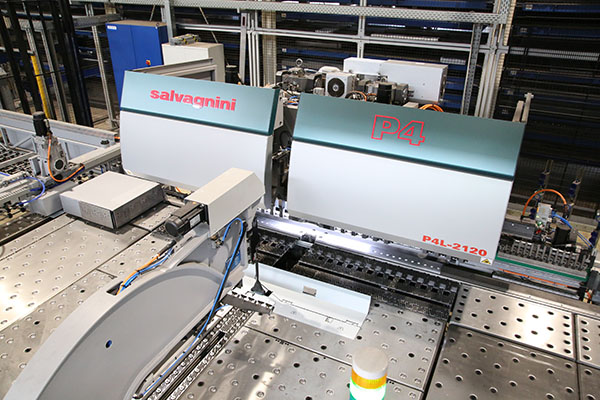

In order to meet the increasing demand for sheet metal parts due to the company's continuous growth, Hargassner needs state-of-the-art machines that guarantee the highest possible level of process reliability. The Salvagnini P4 panel bender replaced one of their outdated bending machines and it had more than exceeded their expectations. - The outcome

After about 6 months of using the system, the Hargassner staff is absolutely thrilled. On average, the panel bender provides a part to be unloaded every 45 seconds, there is almost zero waste. In addition to increased flexibility, Hargassner had considerably increased the output of the sheet metal part production within a brief period, switching back mainly to just-in-time production. With an increase in productivity of about 20%, Hargassner will reach the ROI for the machine sooner than expected. - Some details

Hargassner runs on the P4 panel bender batches from 5 to 100 parts. The majority are the cladding parts for boilers, mainly made of galvanized, coated steel sheets with a thickness between 0.75 and 2 mm. The P4 features make it possible to produce parts that had to be processed in multiple steps entirely on the machine. After bending, a robot removes the parts from the working table and places them in a rack.

Check out the case study

Hear what Markus Hargassner, Managing Director at Hargassner, says about this project.