Case study

FBT Elettronica: sheet metal goes rock

Story courtesy of A. Ariu and G. Mazzola/Lamiera

Leaders in the professional audio industry, FBT Elettronica invested in Salvagnini fiber laser cutting and panel bending technologies. The advantages include process efficiency, significant improvements and shorter production times.

Sheet metal goes rock

Highlights

- FBT Elettronica

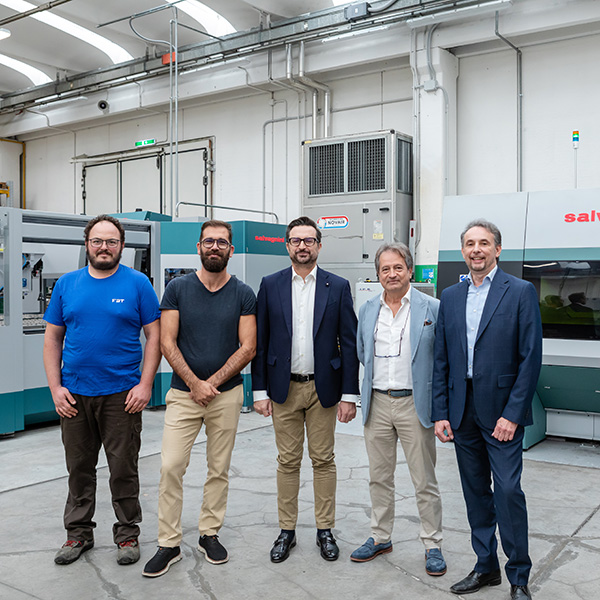

The history of FBT Elettronica began in Recanati in 1963, as a craft workshop producing valve amplifiers for voice and guitar as well as radio mixers. Today, after more than 60 years, the small business has turned into a company of international stature, specialized in the design and production of professional audio equipment, also importing and distributing some major musical instrument brands in Italy. - The context

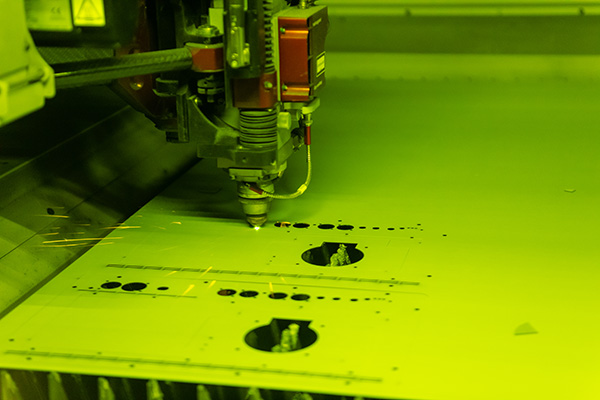

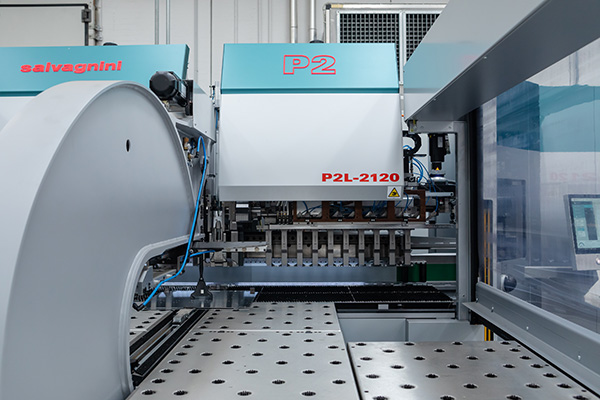

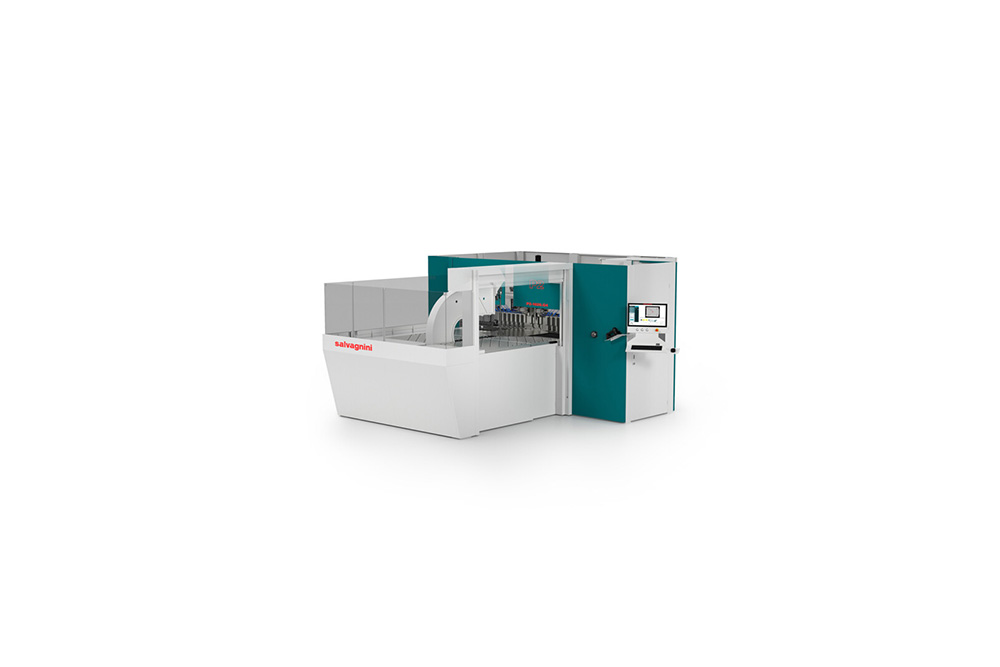

In the FBT Elettronica mechanical workshop today you will find a Salvagnini L5 fiber laser cutting system, complete with LTWS store-tower for loading/unloading, as well as a P2-2120 panel bender. "The choice of adopting these new technologies was dictated by a twofold need," company owner Bruno Tanoni explains. "On one hand, purchasing the fiber laser cutting system has allowed us to manage this process in-house, without having to work with subcontractors any more, and this has brought more independence and optimized our production schedules. The panel bender, on the other hand, was purchased mainly to meet the growing demands in one specific product field". - The project

The Salvagnini laser was chosen by FBT Elettronica in the version L5, with working range up to 3,048 x 1,524 mm and a 4 kW source, ideal for machining steel thicknesses from 0.5 mm to 20 mm, stainless steel and aluminum up to 15 mm and copper and brass up to 8 mm. The system was supplied with some interesting options, including ACUT, AVS and SVS.

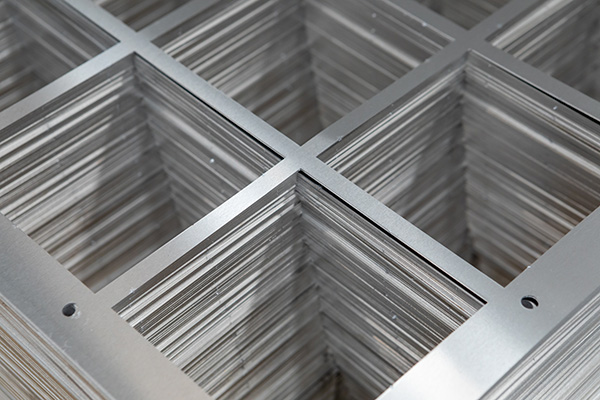

The P2 panel bender was purchased above all to meet the growing demand for the "Install" product segment, including high-quality solutions for fixed installation. From this point of view, Rethinks was decisive. This is a range of custom services made available by the Salvagnini engineers, who put their experience and skills at the disposal of the customers’ designers, helping them to design or re-design their products. "Thanks to Rethinks and Salvagnini’s support", Tanoni explains, "we successfully designed a complete rack, including the interiors, for which a series of complex steps and processes were required before". - The outcome

Salvagnini laser cutting and panel bending technologies have been shown to be fundamental for FBT Elettronica in supporting the market recovery the company has had to tackle, with turnover increasing from 10 million EUR in 2020 to 40 million EUR in 2023. "Our batches vary from 100 to 1,000 parts, demanding great flexibility which, for the sheet metal machining part, we are able to guarantee today with our new Salvagnini systems," Tanoni concludes.

Check out the case study

Hear what Bruno Tanoni, CEO of FBT Elettronica, says about Salvagnini machinery.