Case study

Attention to detail as a principle, excellence as the result

Story courtesy of A. Ariu and G. Mazzola/Lamiera

To improve quality standards in the production of stainless-steel electrical cabinets, Angella has developed a flexible production flow based on cutting-edge Salvagnini bending and panel bending technologies.

Attention to detail as a principle, excellence as the result

Highlights

- Angella

Founded in 1957 in Parma, Italy, Angella is a family-run business specializing in stainless steel electrical cabinets for the food and pharmaceutical industries. Today, over 95% of production is based on AISI 304 and 316 stainless steel, with operations carried out entirely in-house—from design to delivery. - The challenge

Producing small batches with a high level of customization requires extremely accurate bending, especially with stainless steel. Angella needed to improve bend quality, reduce setup times, and maintain production continuity, even when managing variable batches. - The solution

To enhance production flexibility and quality, Angella invested in:

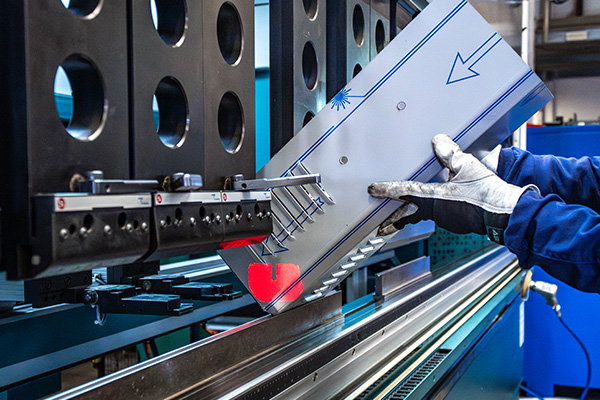

• a Salvagnini P2-2120 panel bender for dynamic, high-precision forming, even of complex geometries;

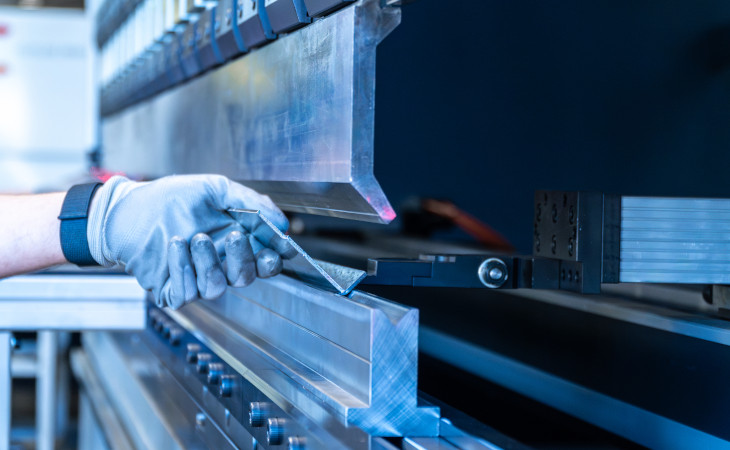

• two B3 hybrid press brakes—a 220-ton model with AU-TO and ATA for automatic tool change, and a 320-ton model with extended daylight and WILA clamping for deep bends up to 600 mm.

The integration of Salvagnini technologies enabled a rationalized bending flow, with specific roles assigned to each machine depending on geometry and depth. - The results

• Higher productivity and setup repeatability thanks to automation.

• Faster changeovers, ideal for one-off or two-off customized batches.

• Improved bending precision.

• A more efficient internal layout and better resource allocation.

• Greater operator ease-of-use due to unified machine interfaces.

As Luca Angella states: "Our goal was to do more, do it better, with greater flexibility and a fully integrated approach to customization.”