Case study

Maximum flexibility...thanks to automation

Story courtesy of G. Giannangeli/Deformazione

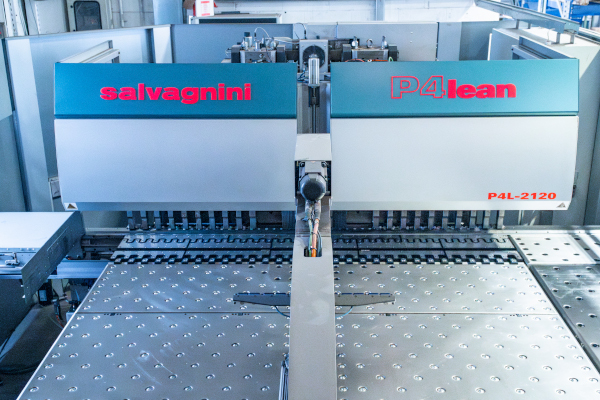

Total control over the sheet metal machining via efficient hardware and software automation eliminates low-value operations and downtime, reducing the cost per part. This is the recipe which has driven the growth of Officina Meccanica OMALL, a Milan-based company which has chosen Salvagnini technology to automate its cutting and panel bending processes with highly flexible solutions.

Maximum flexibility...thanks to automation

Highlights

- OMALL

Founded in 1983 in Gorgonzola, near Milan, OMALL has specialized in sheet metal processing for over 40 years. The company serves the electromechanical, electronics, furniture, elevator, and medical sectors, offering tailored manufacturing from cutting to assembly. - The challenge

As a subcontractor, OMALL manages a high number of codes and small batches. Delivery pressure is intense, requiring just-in-time, often unmanned production—even during night shifts. Automation and flexibility became a strategic need. - The solution

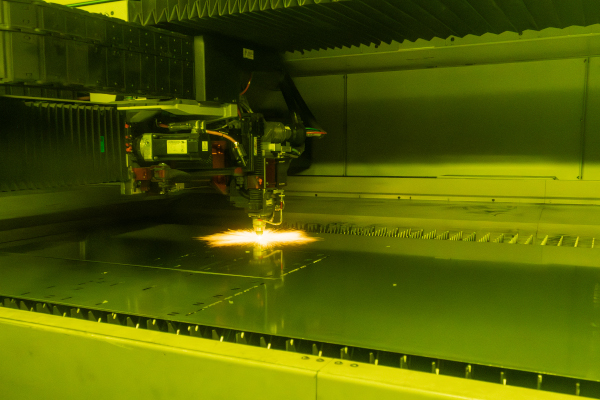

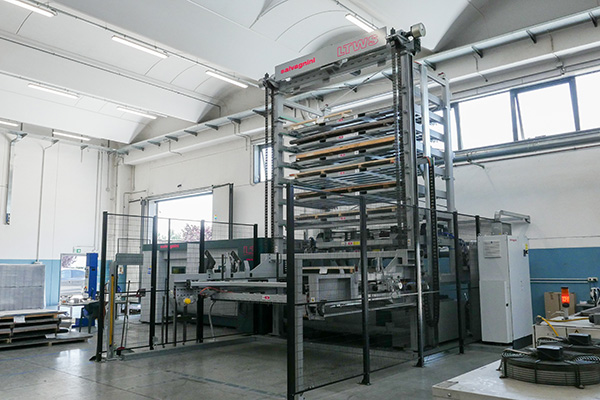

In 2024, OMALL chose Salvagnini, installing a 6 kW L5 fiber laser (3000×1500 mm work area), fed by an 8-tray LTWS tower with loading/unloading automation. A second identical system was added shortly after. - The results

• Unmanned, continuous laser cutting, even on complex small parts.

• Excellent cutting quality with optimal scrap removal.

• Faster production, less manual handling.

• Efficiency gains starting from quoting and nesting stages.