Case study

A scalable path to precision and flow in sheet-metal furniture

AR-CON Hellas, a Greek manufacturer of supermarket fixtures, rebuilt its high-mix sheet-metal flow around a Salvagnini’s P4 panel bender, then scaled upstream with an L5 laser and S4 punching machine. Thea result: batch-size-agnostic bending with consistent precision, shorter lead times, and less dependence on scarce specialists, sustaining predictable throughput and quality.

A scalable path to precision and flow in sheet-metal furniture

Highlights

- AR-CON Hellas

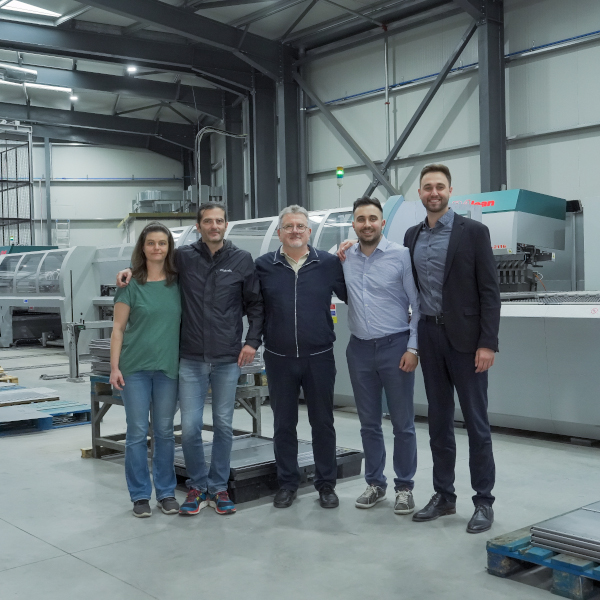

AR-CON Hellas designs, manufactures and installs supermarket/store fixtures for leading Greek retailers. Founded in 1991, it operates from Thessaloniki with a branch in Athens, employs ~120 people and posts ~€10 million turnover. High product variation and custom constructions define its daily workload and growth goals. - The challenge

Bending speed and consistency during frequent changeovers were the true bottlenecks, inflating lead times and operator dependence. Material variability complicated precision. “Almost zero setup time between changes is crucial,” says George Konstantinidis, Chief Executive Manager of the sheet metal department, highlighting risks to throughput, quality and labor utilization. - The solution

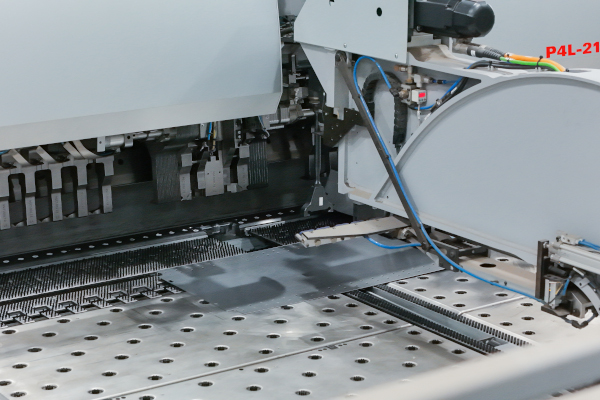

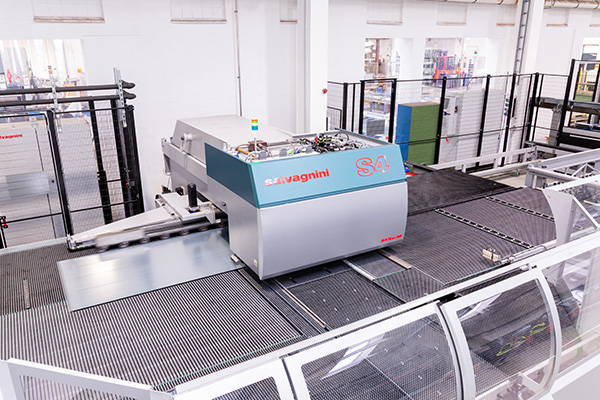

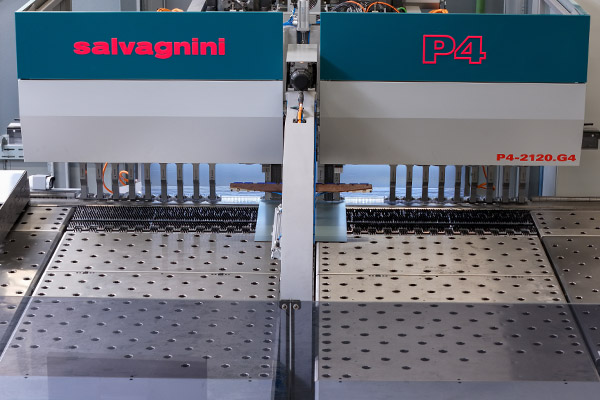

Modernization began in 2017 with a P4-2116 panel bender featuring CLA auxiliary blades, DPM manipulator and MAC 2.0 adaptive control. In 2018 an L5 fiber laser (3 kW) with a 10-tray LTWS, ANC, AVS and ACUT raised upstream autonomy. In 2022 an S4 with MD store closed the loop, forming an integrated S4+P4 line. - The results

A typical part now moves from S4 to finished bends in about 1′45″; around 95% of the main shelving family runs on the S4+P4; one shift yields roughly 650 panels. Lead times shrink, precision stabilizes, and fewer specialists are needed. “You feed the S4+P4…and you know what it will do,” says George Konstantinidis.

Check out the case study

Hear what George Konstantinidis, Chief Executive Manager of the sheet metal department at AR-CON Hellas, says about this project.