Case study

When cutting is flexible and tailor-made

Story courtesy of E. Oldrati/Applicazioni Laser

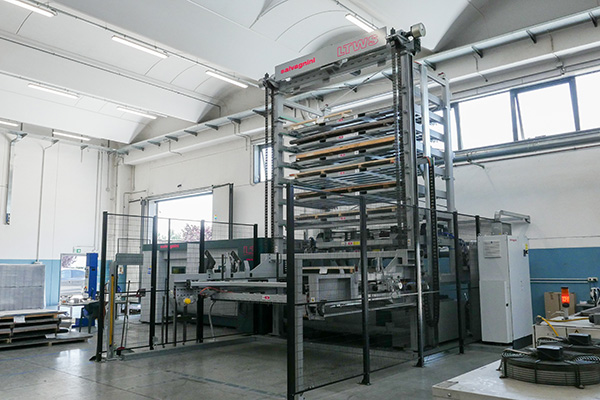

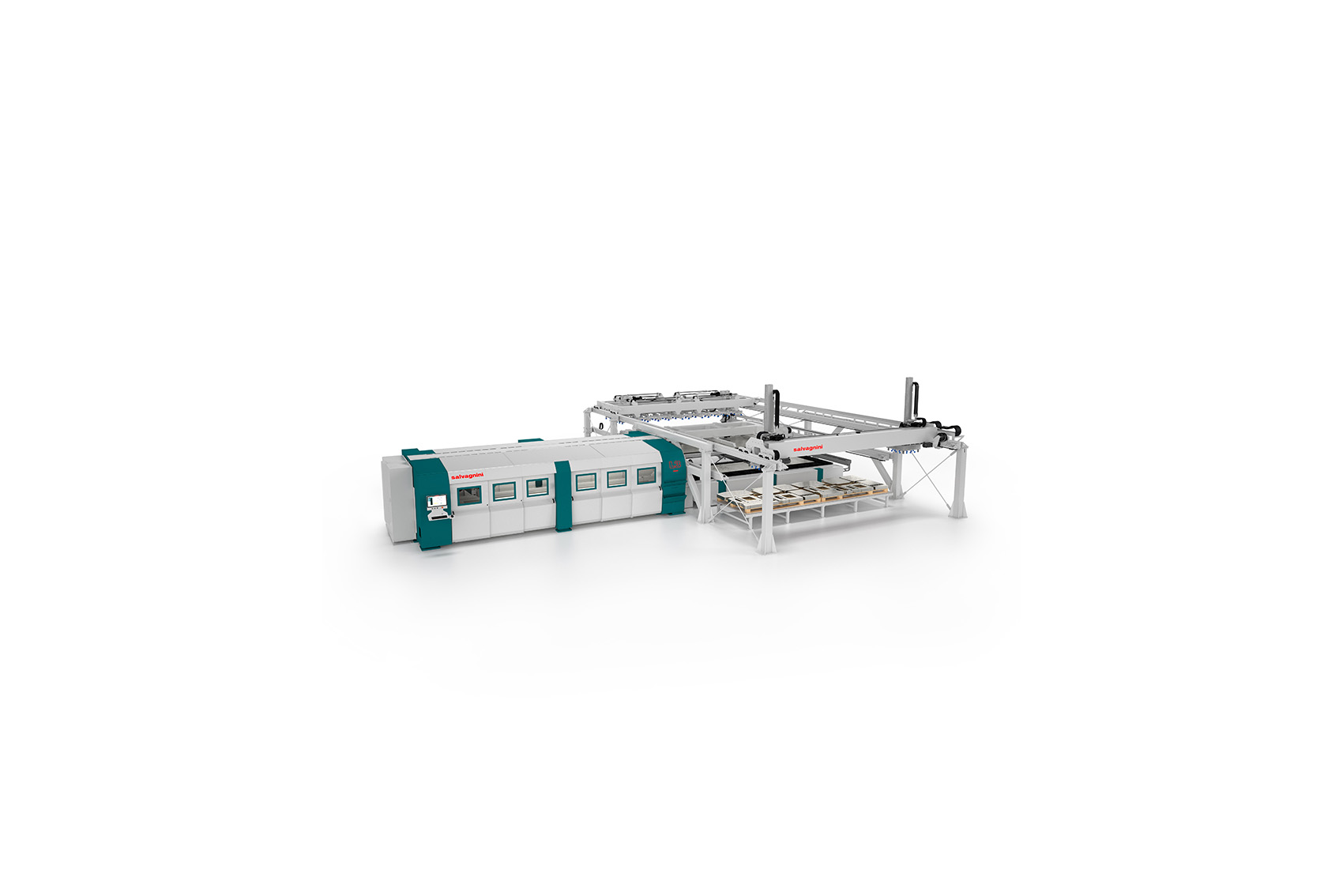

Salvagnini met the needs of the Marchesini Group with an L3 laser cutting system that fitted perfectly into a consolidated production environment, working side by side with an existing store and software already in use, increasing the plant’s reliability and operational flexibility.

When cutting is flexible and tailor-made

Highlights

- Marchesini Group

Marchesini Group, founded in 1974 in Pianoro, manufactures packaging systems for pharmaceuticals and cosmetics. With almost 3,000 employees, a presence in 116+ countries and 87% of turnover from exports, it keeps production in Italy and relies on in-house sheet metal processing to support customized machines. - The challenge

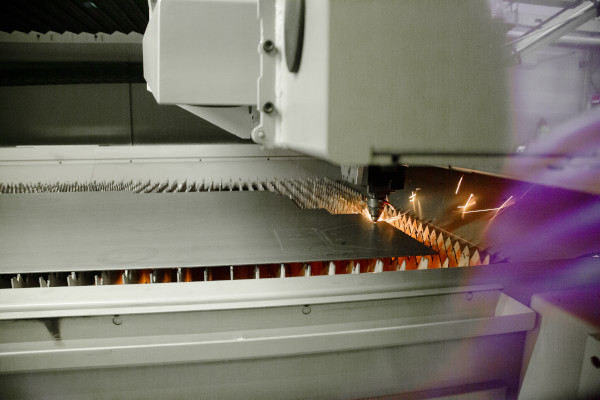

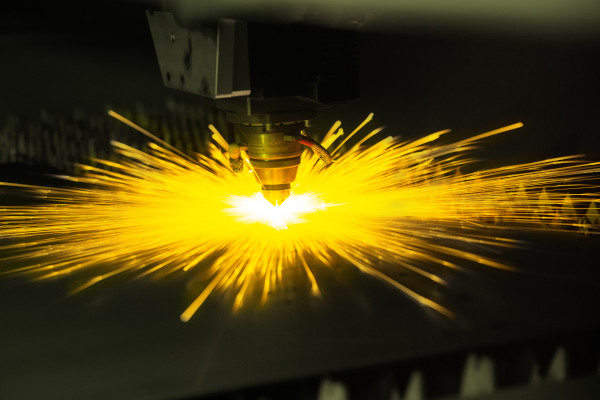

High-mix, one-off nestings mean laser cutting must buffer urgencies without interrupting assembly. The CO2 laser integrated with a 75-tray store cut well, but reliability dropped and energy and maintenance costs rose. "In recent years we have seen problems with reliability, high consumption and costly maintenance," says Mirko Fortunati, Internal Processing Department Coordinator. - The solution

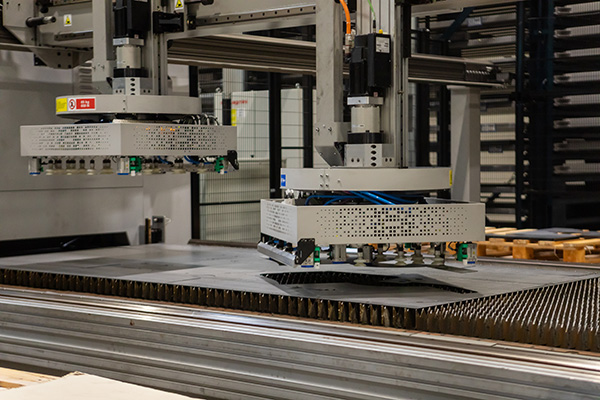

Marchesini replaced the CO2 laser with a 4 kW Salvagnini L3 fiber laser integrated with the existing automated store via a customized ADLU device. ADLU automatically returns leftovers to the store; its independent suction cups handle irregular shapes, while Marchesini’s existing software recognizes them and drives picking. APC2 optimizes piercing and auto-restarts; NVS checks beam centering and nozzle status; ACUT enables treated compressed-air cutting. - The results

Flexibility rose by interlinking nestings of materials and thicknesses for continuous production, and by reusing scrap for new nestings with shorter cycles. Automation reduces operator intervention and supports energy efficiency. "Everything runs automatically, also guaranteeing considerable energy savings," says Fortunati.