Case study

AHT: a world record for punching

Story and pictures courtesy of N. Novotny/Blechtechnik

174,947 operating hours in 25 years: ut was with this impressive world record among Salvagnini systems that a punching system bid AHT Cooling Systems farewell, starting its well-earned retirement and making room for a new Salvagnini S4 punching-shearing system that shines in the machine inventory of this leading supplier of refrigeration systems, with its outstanding productivity and energy efficiency.

A world record for punching

Highlights

- AHT

AHT Cooling Systems GmbH, which is headquartered in Rottenmann, Austria, was established in 1983 and is a world leader with its core business of manufacturing plug-in refrigeration and freezing systems. - The context

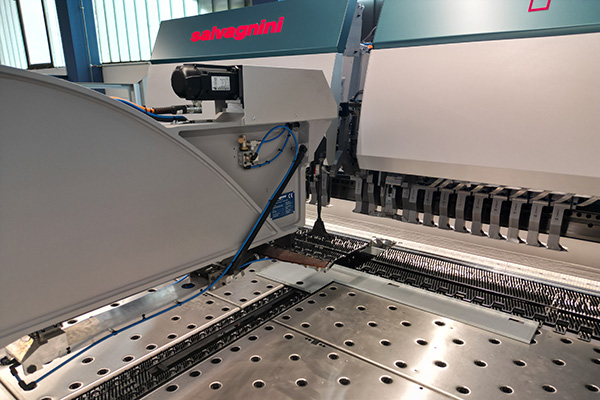

AHT usually produces in small batch sizes, as individual tailor-made solutions are created for each customer. To be able to be mostly independent of suppliers and have direct control over being able to meet its own high quality standards, AHT has relied on Salvagnini punching systems, lasers, panel benders and press brakes since 1996. - The new S4

“The old S4 was always a reliable component of our production. But it has done its job, and has made space for a latest-generation punching system,” says Byörn Tschinkl, Service Engineer at AHT. The production manager, Hermelindis Pollauf, adds: “In addition to a detailed cost-utility analysis, we have also actively involved our machine operators from the punching department in the decision-making process. This has resulted in us opting for another Salvagnini machine.” - The outcome

“In comparison to the old punching systems, with the S4 and its high movement speeds and reduced cycle times, we were able to increase productivity by about 30% – in addition to making energy savings of more than 50%,” says Tschinkl, putting it in a nutshell.

Check out the case study

Hear what AHT executive team says about Salvagnini machinery.