Case study

The technological upgrade that changes the pace of the production flow

Story courtesy of A. Ariu and G.Mazzola/Lamiera

BF Metal extends its machine inventory with a new Salvagnini fiber laser cutting system and panel bender, increasing its production capacity and optimizing its processes while taking new market opportunities.

The technological upgrade that changes the pace of the production flow

Highlights

- BF Metal

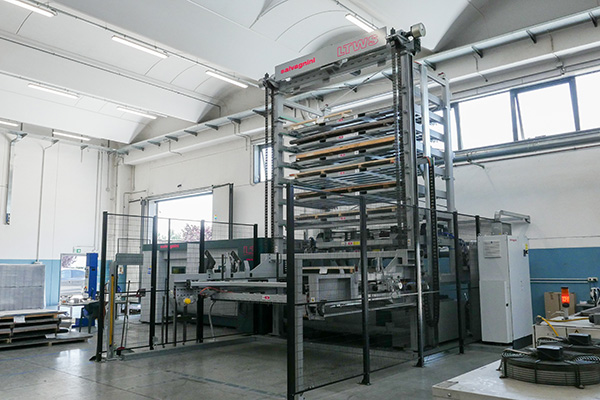

BF Metal was founded in 1973 by Angelo Boselli, a metalworking company originally bearing his own name, and its business developed over the years until, in 1996, his son Andrea joined the firm, bringing with him an innovative vision that was destined to progressively change the business. In 2002, the company invested in its first laser cutting system, followed by a press brake, and in 2011 it transferred to larger premises, also changing the company name but with the same ownership. The innovations continued in 2020 with the purchase of a Salvagnini robotized bending cell and, in 2023, with the new two systems L3-6020 and P4-2525. - The context

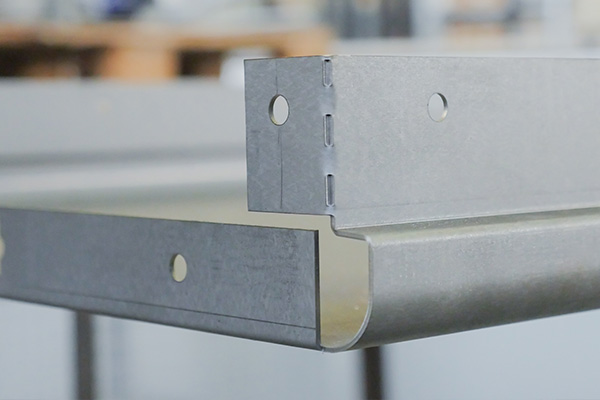

With around a dozen employees, BF Metal – certified to ISO 9001 and, from 2020, IATF 16949 – works mainly in the agricultural and automotive sectors, as well as a variety of metalworking fields. It makes components in different materials (including high-strength anti-wear steels and aluminum), processing over 600 tons of sheet metal a year, in thicknesses from 0.5 to 20 mm. - The project

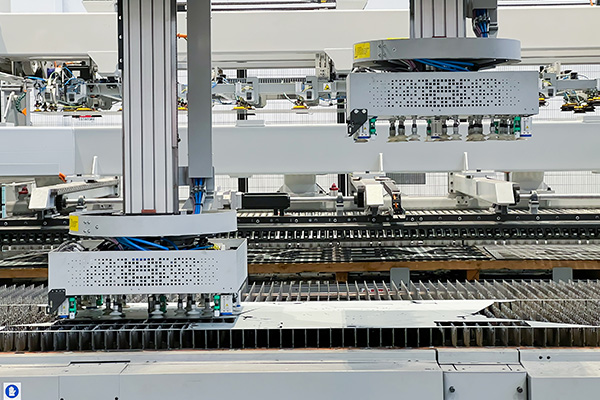

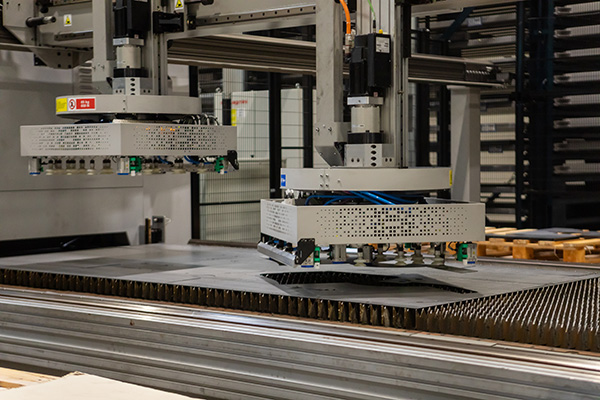

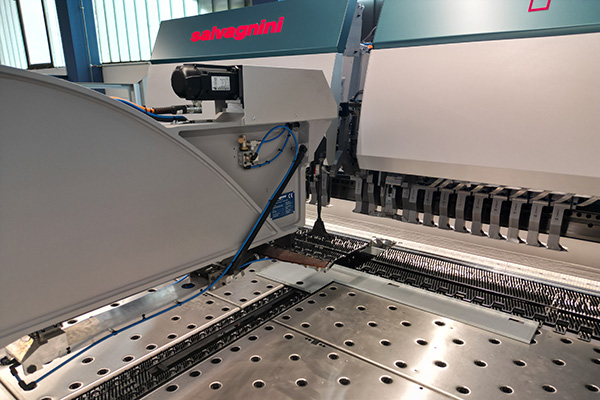

With a view to the continuous improvement of its production capacities, BF Metal has therefore extended its machine inventory in a targeted manner. With an 8 kW source, the L3-6020 has the classic patented Salvagnini load-bearing beam structure, with a lightweight airplane manipulator, which offers advantages including high rigidity, rapidity, positioning precision and accessibility to the whole work area. Boselli (the owner) confirms, “The very high cutting quality and the possibility to cut with compressed air, appropriately treated with the native ACUT option, have brought lower operating costs, with a significant competitive advantage”.

While for BF Metal the fiber laser cutting system has brought process improvements, the introduction of the Salvagnini P4-2525 automatic panel bender marked an expansion and change of operating perspective. Boselli remarks, “We didn't purchase the panel bender to serve a specific sector but rather to improve our production capacity generally". - The outcome

Boselli concludes: "The new technologies have allowed us to expand our customer portfolio, with a consolidated base of around thirty companies, and now we can also serve other sectors”.