Case study

Metalway: passion and innovation, the secrets for continuing to grow

Story courtesy of E. Oldrati/Deformazione

Right from the outset, Metalway has had a clear vision, and in almost 25 years this has led the company to develop significantly, running other major business lines alongside its sheet metal and pipe working subcontracting. Its secret? The desire to never settle and the awareness of the importance of technological innovation, which was translated into the purchase of two Salvagnini systems: an L3 fiber laser cutting system and a P4 automatic panel bender.

Passion and innovation, the secrets for continuing to grow

Highlights

- Metalway

Metalway was founded in 2001 in Tortoreto (TE) to meet the specific needs of the LAS Mobili industrial group, already active in the production of furnishings, chairs and partition walls. The goal was to have a subcontractor specialized in sheet metal and pipe working. In 2015, the company expanded its offering with the Steelbox brand, dedicated to the retail sector, providing designer metal furnishings and sound-proofing solutions. Three seemingly distinct activities that, in reality, represent the different facets of a single entity: Metalway. - The context

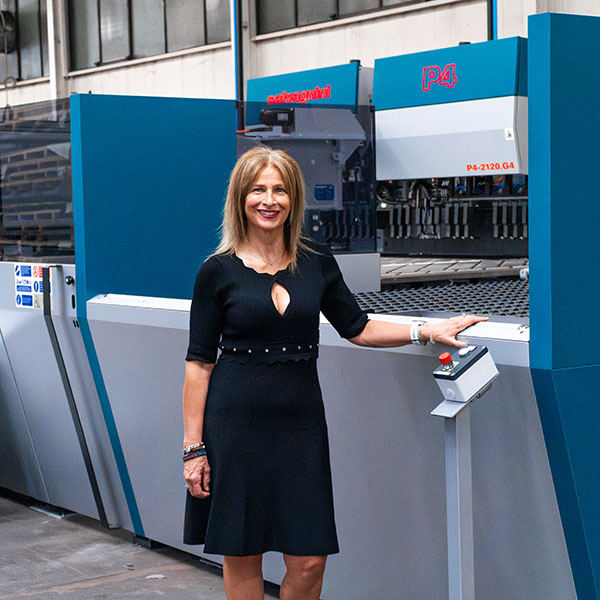

In 2011, Lorella Pedicone, founder and owner of the company, decided to revolutionize Metalway, opening up to new markets and starting a new growth phase. “We wanted to go beyond the niche of our industrial group and look to other customers and markets. This would have meant increasing our turnover, but also our production volumes. And to do this we needed new systems and machinery in line with our vision and strategy”. Technological innovation marked a turning point. Thus began a phase of huge growth, which quickly took Metalway to working on three shifts, managing batches of all sizes while ensuring quality, punctuality and speed. - The project

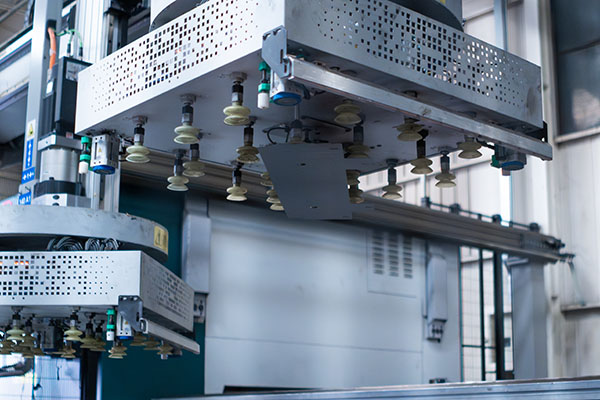

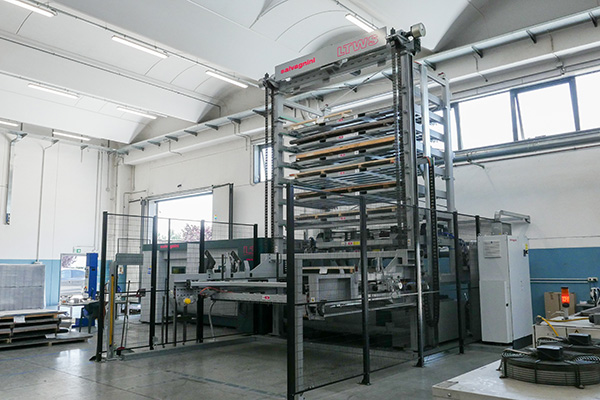

In 2021, Metalway took another major step, adding a Salvagnini L3 fiber laser cutting system that profoundly changed their production. The machine was incorporated in the production flow and began to produce immediately and highly efficiently. The L3 system installed at Metalway is fed by an ADLL loading and unloading automation combined with an MCU sorting system. With the L3 laser cutting is always with compressed air, which drastically reduces gas costs. Furthermore, in 2024 Metalway introduced a P4 Salvagnini automatic panel bender. “The evolution on the previous panel bender was huge: for example, we were very impressed by the P4’s ability to adapt in real time to the characteristics of the material being processed to guarantee the precision, repeatability and quality of the finished product", explains Lorella Pedicone. - The outcome

“I am really pleased with the L3,” the owner of Metalway continues, “not only because it offers extremely high performance in cutting but also very efficient in production terms". Concerning the production side, the Salvagnini laser has also significantly expanded the range of metals that can be cut during production. “Today Metalway can machine aluminum, steel and stainless steel. This has allowed us to enter new markets which, before the laser, were precluded for us”. One fundamental need Metalway had was also that the panel bender could manage the huge variability of the company. "The P4 passes very quickly from the production of small parts to bending large parts without retooling downtimes. This flexibility and speed are fundamental for us. Once we have completely transitioned from our old panel bender to the P4, the Salvagnini machine will become central to our production", concludes Lorella Pedicone.