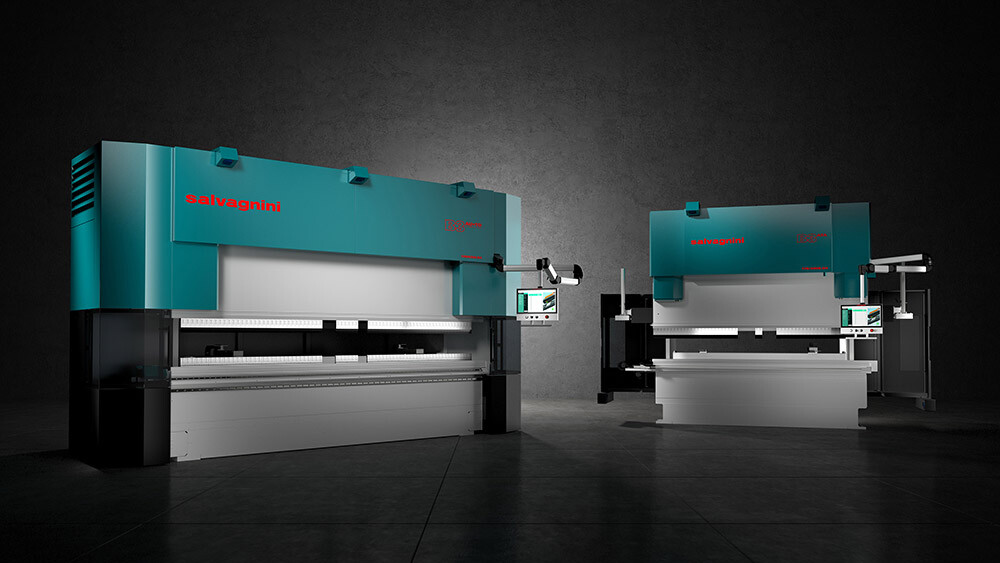

Press brakes

Precision engineering for high-end sheet metal bending

Salvagnini press brakes are intelligent, high-performance machines designed for manufacturers who demand precision, repeatability, and advanced process control. They feature high-end technologies such as S-Crowning, which actively compensates for deflection during bending, and TFC2.0, an intelligent control system that ensures consistent quality across batches. These features minimize operator intervention, enabling efficient production even with complex geometries or material variations. Positioned at the upper end of the market, Salvagnini’s press brake machines combine structural rigidity, smart software solution, and a compact footprint to deliver superior results across a broad spectrum of applications.

From smart bending to fully automated systems

To further enhance productivity and flexibility, Salvagnini offers a range of optional automation and features that transform its press brakes into fully automated bending systems. These include the AU-TO automatic tool changer, the ATA automatic tool adjusters, the MVM automatically adjustable V die, and the AMS angle measurement system. These modular solutions are designed to address the most common pain points in metal forming such as long tool changeovers, operator variability, and the inefficiencies of mixed-volume production. By integrating scalable automation, Salvagnini’s automated press brakes support seamless transitions between different jobs, maximizing uptime and enabling true lean manufacturing. Whether for small batches or high-volume runs, these systems deliver unmatched precision, flexibility, and return on investment.

Product range

The B3 was designed by combining the features and benefits of electric and hydraulic press brakes with Salvagnini’s in-depth knowledge of automation, software, mechanics and electronics.

Learn moreDirect Drive

Ram movements are driven by two independent direct-drive brushless motors, which allow both fast approach and fast return movements to be achieved, with speeds as high as 250 mm/s.

Unbeatable stroke

Salvagnini offers a wide range of models, with strokes of 300 to 450 mm according to size, to meet all production requirements and maximize the use of the press brake.

Software

Industry has changed: flexibility and efficiency are fundamental requirements for managing increasingly smaller batches or rapid item turnover rate. And developments in technology have in some way upset the balance between workloads, with increasingly fast systems which however need to be guided by more and more specific machine programs, the generation of which is increasingly time-consuming. This is why software is increasingly crucial to improving the efficiency of machinery.

Salvagnini’s IoT solution, increases the global efficiency of the press brake. LINKS allows real-time monitoring of the machine’s performance and independent analysis.

Do you have any questions?