Case study

E.T.A.: incorporating the best in automation for flexible production

Story courtesy of A. Ariu and G. Mazzola/Lamiera

The high variability of increasingly small batches requires the ability to optimize a wide range of production change needs. Manufacturer of enclosures for the automation world, E.T.A. meets its needs using Salvagnini cutting, panel bending, storage and sorting technologies, all fully integrated to guarantee even unmanned productivity and flexibility.

Incorporating the best in automation for flexible production

Highlights

- E.T.A.

E.T.A., founded in 1978 in Castelmarte (CO), has built its reputation as a benchmark in the worldwide industrial automation scene, finding appreciation both in Italy and beyond the national borders. Some of the representative figures of these first 45 years of company history: €50 million turnover, 65,000 m2 of operational area (of which 35,000 m2 indoor), 220 employees working in the plants in Albavilla and Canzo (CO). - The context

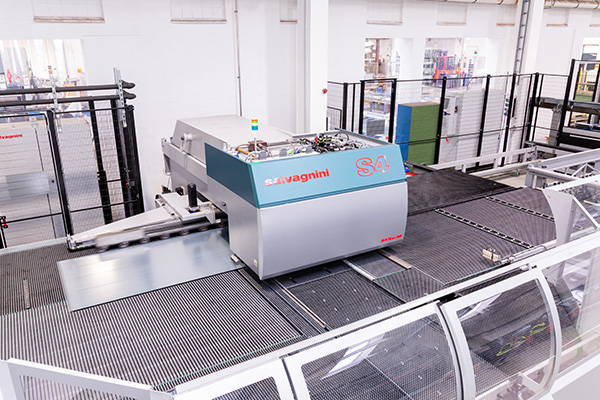

E.T.A. has made product customization and diversification and process automation the cornerstones for maintaining the highest levels of competitive performance on the market. These ambitious growth targets have also been achieved also thanks to Salvagnini technologies: after the first P4-2512 panel bender installed in 1996, 4 more were installed. This is followed by the integration of the S4 punching-shearing center and the L5 high-dynamic fiber laser, representatives of a thorough reorganization of all production lines, aiming to achieve greater efficiency. - The project

At the site in Canzo, E.T.A. produces ENUX cable entry modules, EMOX monobloc cabinets and ECOMP compact solutions, with separate work flows depending on the type of incoming raw material, which may be in coils or stainless steel sheets. In the first case, the coils are picked from a storage area and sent to the flattening line before passing on to the S4 punching-shearing center and, subsequently, again automatically, to the P4 panel benders. The stainless steel sheets in various commercial formats are stored in the new MV tray store before being processed by the L5 high-dynamic fiber laser. - The outcome

For E.T.A., technological innovation and automation are differentiating elements that make it one of the first companies in its sector to have started to use (in 1996) a (Salvagnini) automatic panel bender, and to have introduced laser welding. "Today, having a highly automated department like the one equipped with Salvagnini technologies merely further increases our competitive performance on the market", the Chairman Aldo Turati concludes.