Case study

La Nordica: sheet metal is transformed…to warm up our lives

Story courtesy of F. Boiocchi and A. Ariu/Lamiera

La Nordica-Extraflame’s household heating solutions are designed and built solely in Italy by the Vicenza-based group. Thanks to painstaking research in the construction and environmental sustainability fields, they are capable of guaranteeing low levels of emissions and minimum pollution, as well as the best output while saving you considerable amounts of money. These features are also the distinguishing traits of Salvagnini systems, which are used to produce the aesthetic, internal and functional parts of numerous different types of stoves, cookers, fireplaces and boilers.

Sheet metal is transformed…to warm up our lives

Highlights

- La Nordica

More than 200 models currently make up La Nordica-Extraflame’s product range, including stoves, cookers, fireplaces, wood-burning boilers and pellet-burning boilers. From the 1960s onwards, production has been transformed from a craft-based business to an industrial scale, but the love and passion have not wavered. Over time, this journey has led the Group to succeed in an international market in over 50 countries worldwide, with an increasingly high-tech offering, entirely Made in Italy, for the production of energy for biomass-powered household heating. - The context

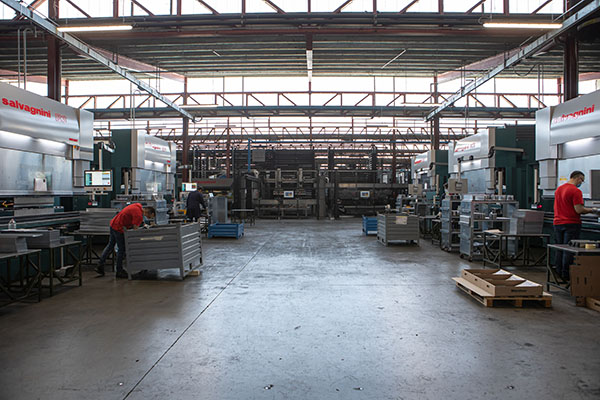

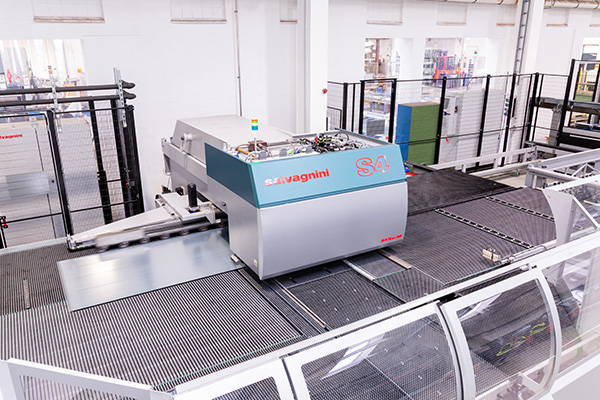

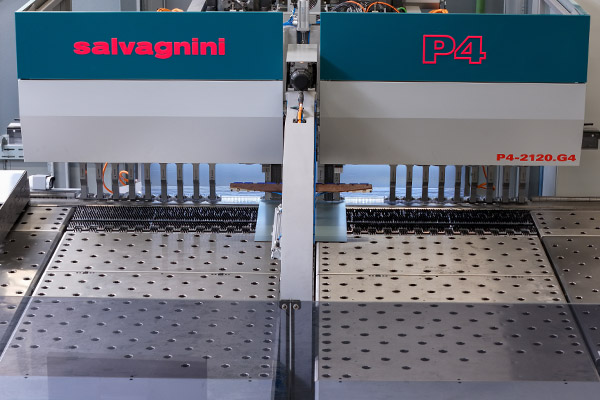

Several Salvagnini systems have been in operation at La Nordica’s plants in Montecchio Precalcino since 2009: an MV automatic tray store, an S4 punching-shearing machine, a P4 panel bender. - The project

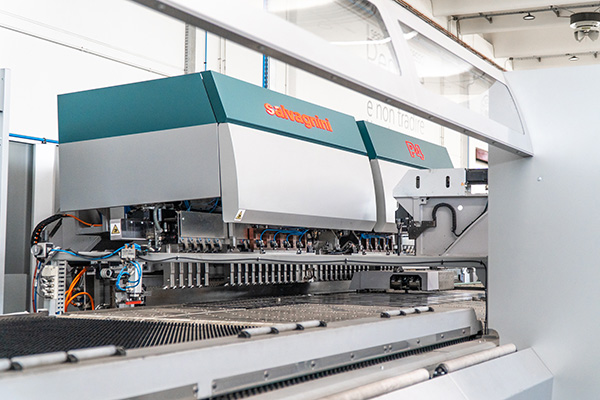

A new major investment was made in 2020, including a new L5 fiber laser cutting system, with a 4 kW source, complete with ADLL loading/unloading automation and an MCU automatic sorting system. And that’s not all, because La Nordica also has no fewer than five B3 3-meter 100-ton bending presses.