Case study

Tecnolaser: not just a subcontractor

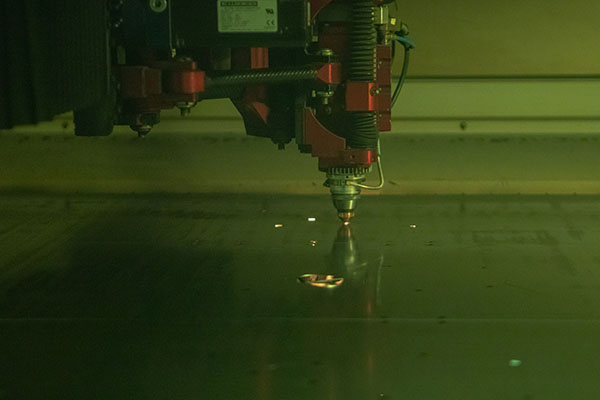

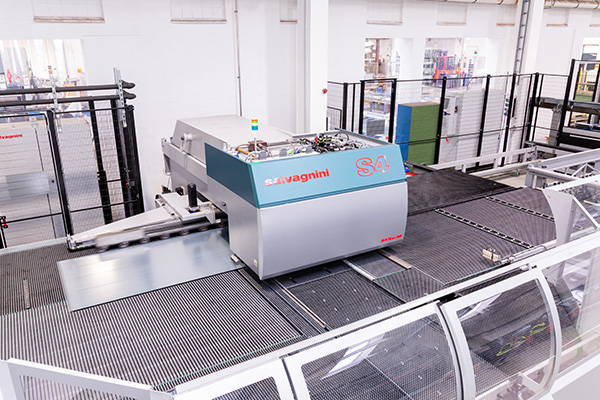

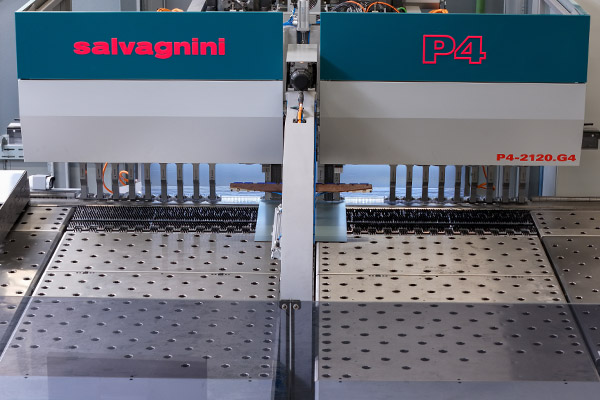

In 1986, it was one of the first companies in the north-east of Italy to choose laser cutting technology. Yet Tecnolaser, a leading subcontractor in Veneto and beyond, developed rapidly to offer as many sheet metalworking processes as possible: in addition to cutting, managed by an impressive Salvagnini automated store-tower, the Curtarolo-based company also provides bending, mechanical machining, welding, painting and assembly services, in addition to design, prototyping and industrialization. An advanced subcontractor, who continues to provide active support to the whole production process and whose strengths are based on experience, competence and a top-quality production layout.

Not just a subcontractor

Highlights

- Tecnolaser

Tecnolaser is a spin-off of the company Officine Facco, active in the poultry equipment sector. When the company restructured in 1986, Tecnolaser was born. This new company not only took over Facco's production, but also focused on other customers in the area from then on. The company has around 150 employees, and covers an area of 40,000 m2 28,000 of which are covered and all of which are used for production. The average annual turnover is around €25 mln. - Full service, 24/7

Tecnolaser is organized to work even 24/7: the Salvagnini MV sheet metal store, with its 900 trays, automatically feeds six Salvagnini L1, L2, L3 and L5 laser cutting systems, one Salvagnini S4 punching-shearing center and two combined machines, guaranteeing high production capacity. - Digitalization & OPS

In 2014 Tecnolaser launched a major digitalization program. And in this project too, the partnership with Salvagnini played a vital role, leading to the implementation of OPS, the proprietary production management software. Once the project had been completed, the impact of OPS was amazing: the average time needed to manage an order and deliver the programs to the machine fell from 5 days to around 2 hours – a 95% reduction.