Case study

REM-IRU: efficiency through technology and experience

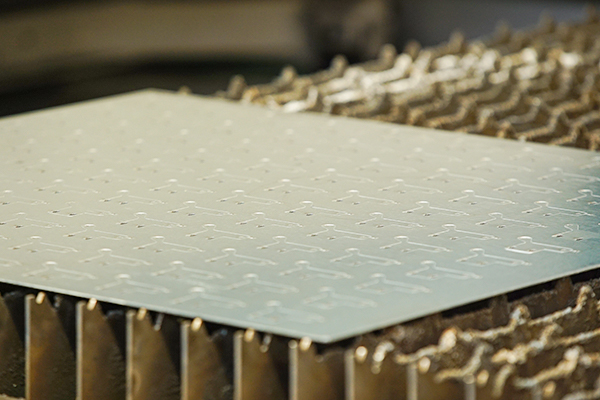

REM-IRU is a subcontractor specializing in sheet metal working for several different industries. Laser cutting, punching, bending, panel bending, welding, and assembly are handled in-house, while a network of suppliers handles painting, surface treatments, and other auxiliary operations.

Efficiency through technology and experience

Highlights

- REM-IRU

Renewing and evolving with the market is part of REM-IRU's DNA, along with its ability to immediately capture the potential of new technologies, at least on the Spanish market. Not by chance, the Ruiz family business was the first subcontractor in Spain to install a panel bender. Relations between REM-IRU and Salvagnini are not limited only to panel benders, however. Although it aims to diversify both its customers and its suppliers, the company from Vitoria-Gasteiz also uses an L3 fiber laser and an S4 punching machine. - Focus on panel benders

"In Spain, only businesses with their own products and large volumes adopted panel bending techniques, and the reason is simple," explains Judith Ruiz, CEO of REM-IRU. "The cost-per-hour of a conventional press brake and that of a panel bender are very different. But the panel bender has allowed us to significantly increase both quality and productivity."