Case study

Flexibility is the winning card

Story courtesy of E. Oldrati/Deformazione

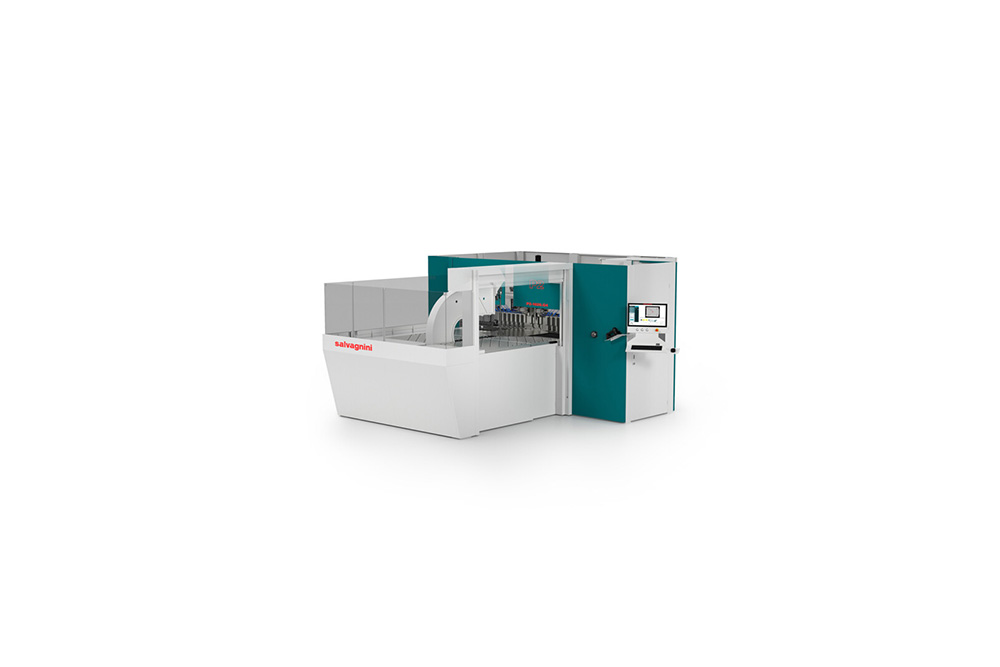

Located in Marsala, in the province of Trapani (Sicily), Ausonia specializes in the production of generator sets over the years, and continues to grow. This growth has gone hand in hand with major investments in production technologies, particularly in the sheet metal department where a B3 press brake recently completed the machine fleet, which also includes a Salvagnini laser machine and panel bender.

Flexibility is the winning card

Highlights

- Ausonia

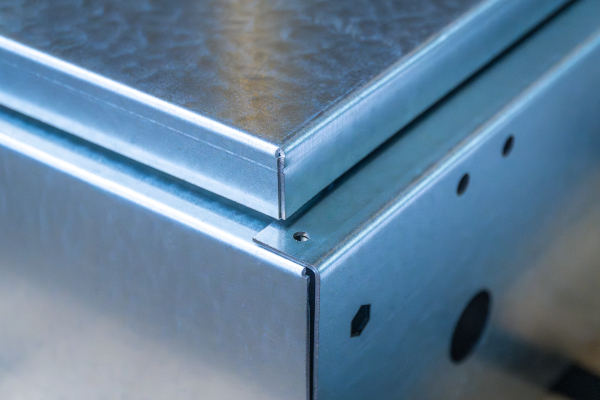

Ausonia, based in Marsala (Sicily), designs and manufactures integrated electricity and heat generation systems. Its wide genset range serves telecoms, public utilities, defense, transport, healthcare, oil and infrastructure. Founded about a century ago, it now distributes worldwide: in Europe, Africa, and the Middle East. - The challenge

To sustain growth, Ausonia has been overhauling sheet-metal operations to minimize semi-finished inventory, waste and inefficiencies, and to guarantee predictable delivery times. Parts with specific geometries required press-brake processing; layout and handling created constraints on flow and floor space, putting throughput and on-time delivery KPIs under pressure. - The solution

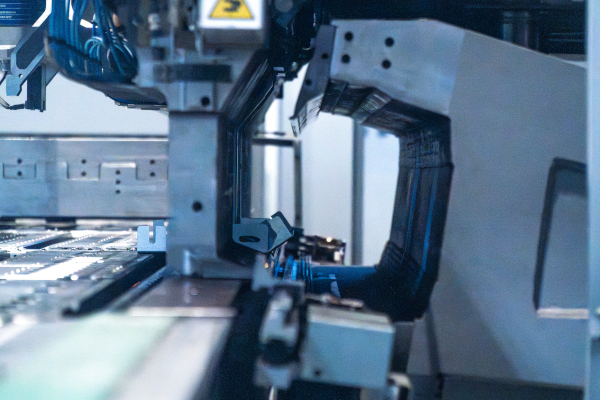

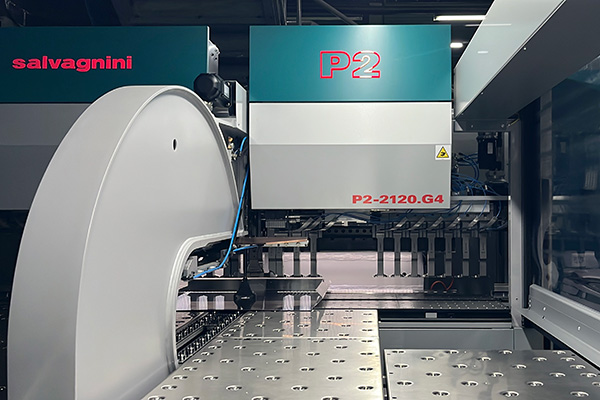

A single Salvagnini cell: L5 fiber laser with two-tower LTWS store, P4-2520 panel bender, and a fourth-generation B3 press brake (170 t, 4250 mm, four backgauges). STREAM programs all three machines in one environment; OPS connects ERP/MRP; LINKS supports condition monitoring. The machines are arranged in a compact circular layout. - The results

With B3, the layout is complete: intermediate handling shrank to a few meters and space use improved. Programming happens in the office while the workshop runs another job, raising efficiency. Direct Drive and adaptive S-CROWNING/TFC2.0 stabilize quality and cut operating costs. "Installing the B3 removed the final constraints, to the full advantage of the production flow," says Massimo Ombra, CEO of Ausonia.