Case study

An S1 + P4 line for infrastructure solutions

Story and pictures courtesy of VCG/Finus

GRITEC set out to redesign sheet-metal flow for doors and ventilation components: synchronize cutting, punching and bending, and reduce manual handoffs. The goal was inline processing from nesting to bending, tight tolerances, and capacity for delicate narrow profiles and special bends within one coordinated process.

An S1 + P4 line for infrastructure solutions

Highlights

- GRITEC

GRITEC is a leading German supplier of technical buildings for critical infrastructures. For over 60 years it supports electricity, gas, water, telecoms, rail and e-mobility projects. Around 1,300 employees across six sites deliver 10,000+ projects yearly; GRITEC Elements manufactures doors and ventilation components in-house. - The challenge

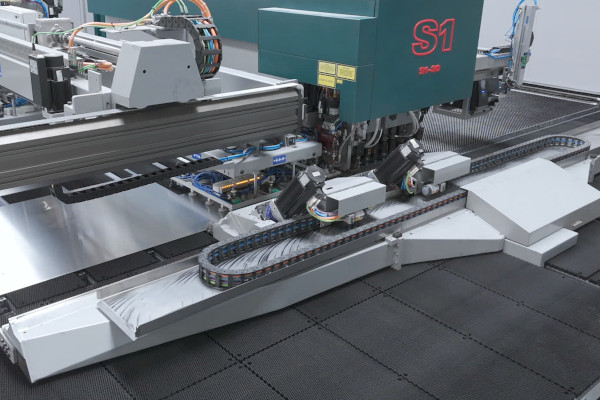

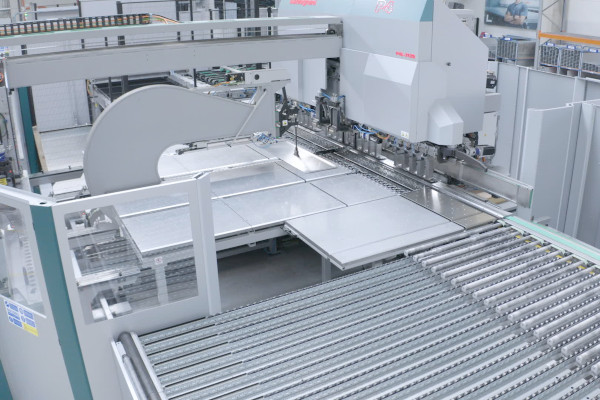

Producing security doors and ventilation grilles that prevent unauthorized access and withstand pressure surges from faults demanded tight tolerances and repeatable quality. Prior to automation, manual handoffs between cutting, punching and bending created rework and inventory; delicate, small profiles could not be made automatically. - The solution

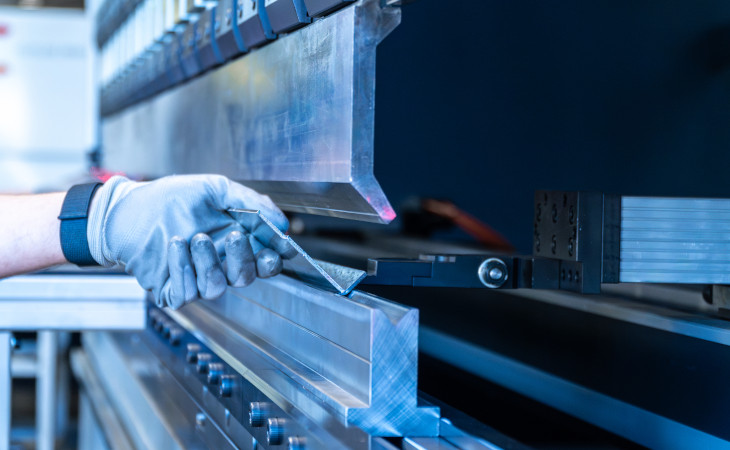

GRITEC implemented an integrated flexible manufacturing system centered on a Salvagnini S1+P4 line. An automatic MV tray store feeds the S1 punch–laser combi; the TML automatic sorting device then receives parts and conveys them inline to the P4 panel bender. Punching-laser-only parts can also be stacked and discharged from the system when required. The P4 provides up to 3,100 mm bending length and 254 mm bending height, and features an automatically adjustable blankholder that adapts tool length in masked time—no downtime or manual re-tooling. To extend capability for special bends outside the P4’s range, GRITEC added a Salvagnini B3 press brake: the P-PB-CXN software directly links the panel bender and press brake, automatically loading the B3 program at the end of the P4 cycle. - The results

The S1+P4 cell reduced scrap, raised cutting quality and eliminated rework; day-exact production lowered material inventory. Assembly sped up thanks to tighter tolerances, and productivity rose further when B3 programs auto-loaded from P4. “We no longer have manual handling between cutting, punching and bending,” says Kevin Bühler, PPS/Production Technology Manager.

Check out the case study

Hear what Volker Knott, Metalworking Plant Manager, and Kevin Bühler, Production Planning & Control Manager at GRITEC, say about this project.