Case study

Busung Everest: revolutionizing the refrigeration industry with a Salvagnini P2 panel bender

Busung Everest, a Korean company specializing in commercial refrigeration, has revolutionized production thanks to Salvagnini panel benders. Automation has doubled production capacity, significantly increasing productivity, quality, and revenue, while also promoting the inclusion of women in production.

Revolutionizing the refrigeration industry with a Salvagnini P2 panel bender

Highlights

- Busung Everest

Busung Everest, which began as Busung Refrigeration in 1984, has achieved steady growth since entering the refrigerator business in 1998. With the establishment of its corporate entity in 2018, the company reached a significant turning point and now employs over 150 people. It operates under two entities: Busung and Busung Everest. Busung Everest specializes in manufacturing a wide range of products, including commercial refrigerators, table refrigerators, showcases, wine aging cabinets, and mortuary refrigerators. - The context

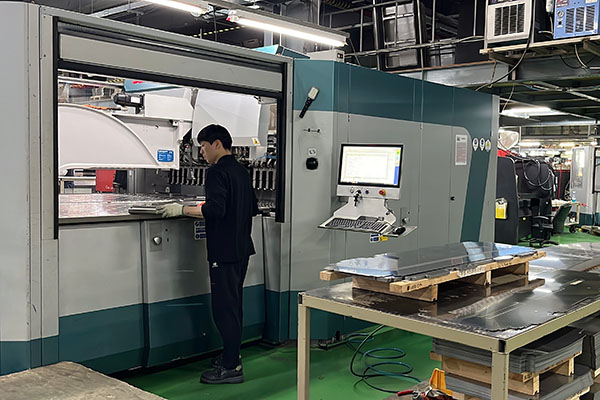

Busung Everest began incorporating automatic bending into its production processes in the early 2000s, being the first company in the South Korean's refrigeration industry to adopt a Salvagnini panel bender. The company chairman’s vision was to redesign all products through panel bending. Compared to manual bending machines the company used in the beginning, the advanced Salvagnini systems have enabled Busung Everest to double the production capacity while reducing labor requirements by half, significantly increasing productivity, quality, and revenue. After the initial installation of a Salvagnini P2, the noticeable enhancement in efficiency naturally led to additional purchases. Today five P2 panel benders operate at the Busung Everest plant, plus one Salvagnini’s P1. - The project

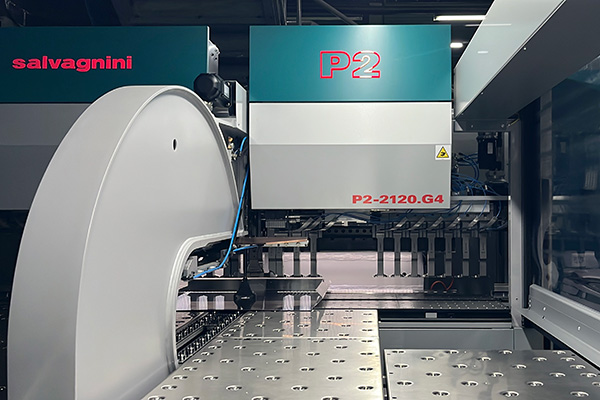

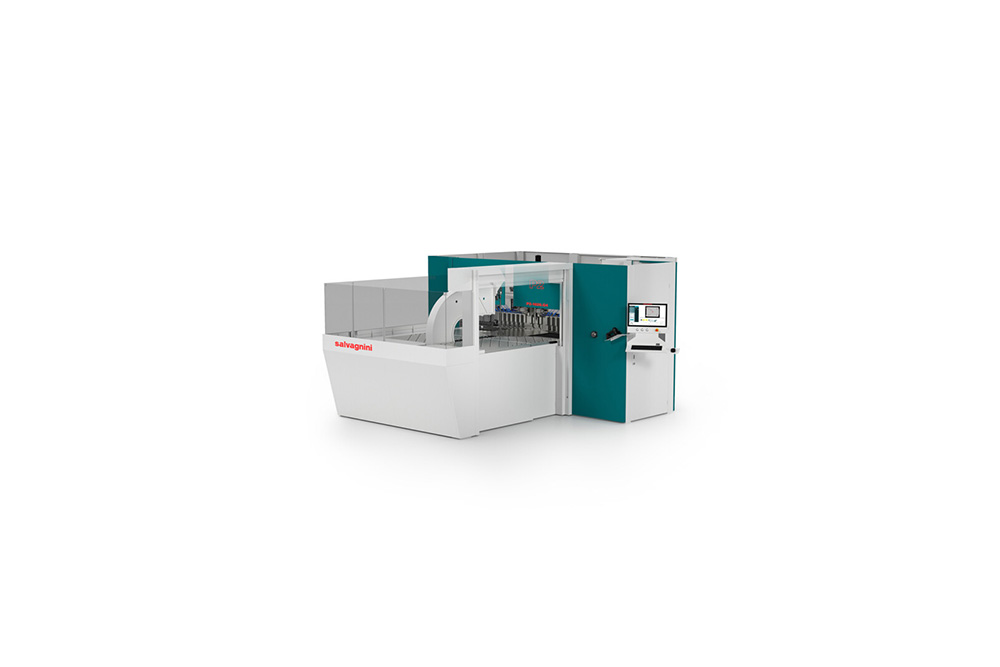

The latest model chosen by Busung Everest, the compact P2-2120.G4 with the manual loading/unloading, natively combines productivity, with automatic bending and handling cycles with an average of 17 bends per minute, and flexibility, with its universal bending tools. No re-tooling is required because the upper and lower blades, counterblade and blankholder are universal tools able to process the whole range of thicknesses and machinable materials. P2-2120.G4 is equipped with ABA (Auto Blankholder Adjuster) technology that makes it exceptionally efficient for small-batch and high-mix production. MAC3.0 allows it to adapt to the material being machined by measuring the tensile strength in real time. Moreover, like the whole range of its products, Salvagnini’s P2 panel bender is also extremely ease of use thanks to FACE the Salvagnini HMI that reduces the time required for interaction. - The outcome

Among the many advantages resulting from the adoption of automatic bending at Busung Everest, one is certainly the increased participation of women operators. In fact, the Salvagnini P1 panel bender, which is particularly suitable for handling lightweight materials, is making it easy for female employees to operate. Enhancing both inclusivity and efficiency in the workplace. "We prioritize diversity in our work environment. The increased participation of women operators has brought a new dynamic to the workflow and further improved efficiency", Jungwoo Han, Manager of the company, explains.