Case study

Primatech: the missing link in thin sheet metal processing

Story and pictures courtesy of N. Novotny/Blechtechnik

As a supplier for system, vehicle and mechanical engineering sectors, Primatech is a specialist in the production of assembled items and welded components. At the beginning of 2023, the highly automated machinery was expanded to include Salvagnini panel bending.

Panel bending massively increases output

Highlights

- Primatech

Primatech GmbH, established in 2006 in the Upper Austrian town of St. Marienkirchen near Schärding, has operated in the area of metal processing and until today has developed brilliantly. With the new construction of a head office and production hall with a modern infrastructure and best production conditions in 2021, the subcontractor has set the requirements for consistently implementing its long-term strategy of entering the market for functional assembly production. - The context

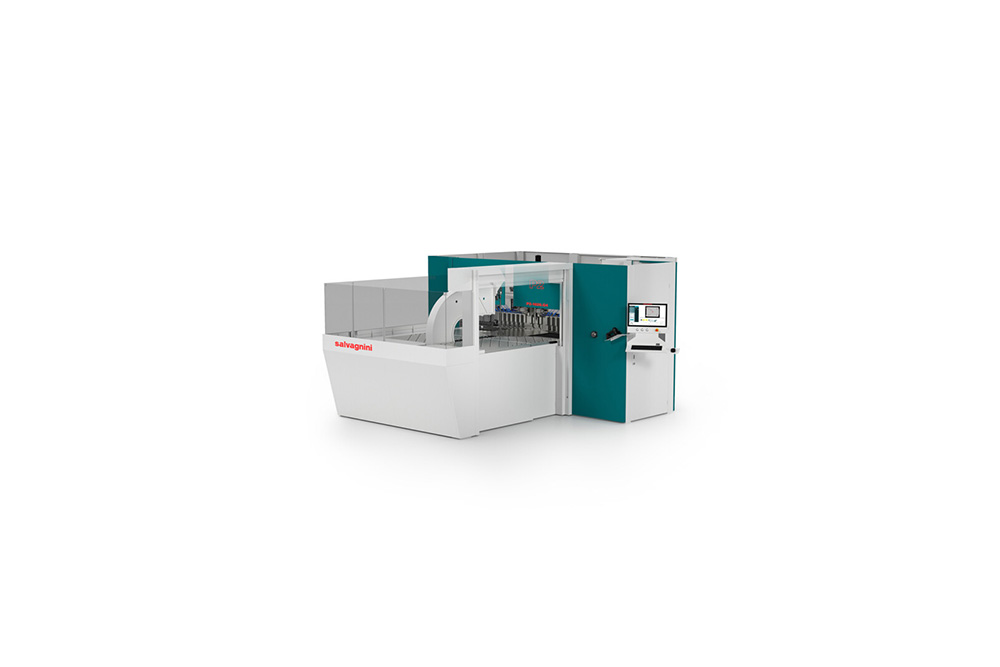

Primatech has implemented fully-automated sheet metal processing in which numerous top-level machines cover the entire spectrum of sheet metal processing. Primatech was also already well equipped for bending with conventional press brakes, press brakes equipped with an automatic tool changer as well as fully-automated bending cells. Due to the increase in contracts for thin sheet metal processing, the company implemented a technology that is predestined for this purpose, by purchasing a new Salvagnini P2-2120 panel bender. - The project

The P2 panel bender has been in use in St. Marienkirchen bei Schärding since the beginning of February 2023. It makes it possible to process thin sheet metal down to material thicknesses of 3.2 mm. Parts with a bending length of max. 2180 mm and a bending height of max. 203 mm can be produced on the P2-2120. - The outcome

"The differences in speed for certain parts in comparison to production even on our automatic press brakes is tremendous. Salvagnini panel bender was the so-called missing link that our production system didn't have. The new P2 made massively increased our output for thin sheet metal processing. The high quality of the P2, which works without any marks or scratches, simply cannot be obtained with press brakes," says Christoph Standfest, CFO of Primatech. "As a contract manufacturer is it essential to be able to offer this technology. With Salvagnini we selected the absolutely best partner for this," adds the owner and CEO Johann Kasper.

Check out the case study

Hear what Johann Kasper, CEO of Primatech GmbH, says about this project.