Case study

Flexible panel bender for maximum production efficiency

Story courtesy of N. Novotny/Blechtechnik

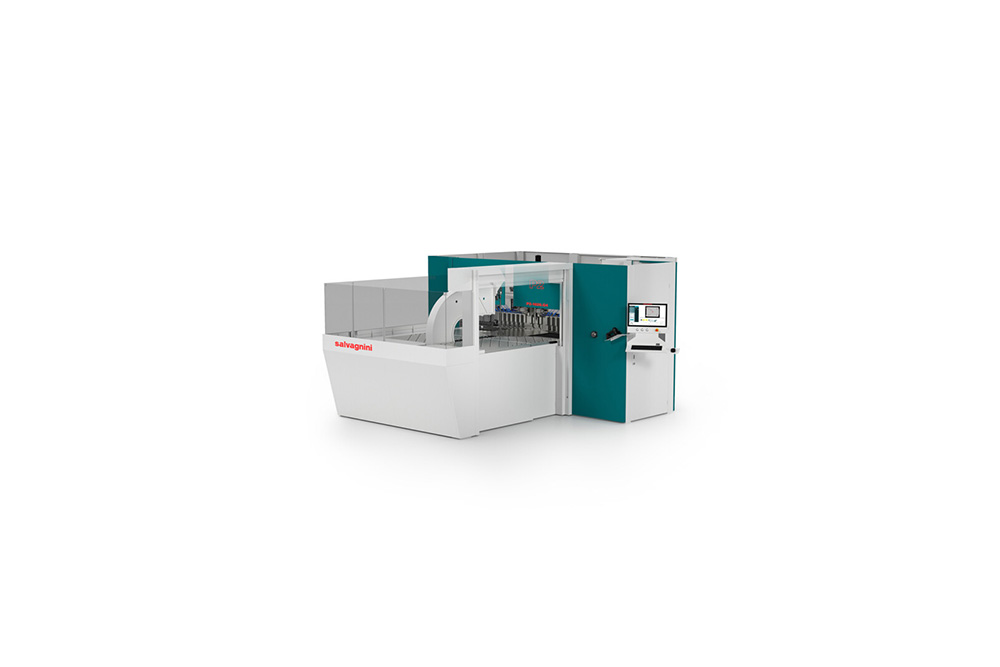

The increasing variety in the production of office furniture, laboratory furniture systems and HVAC, as well as its continuously growing customer base have driven Marchhart GmbH to expand its bending equipment. Since the end of 2024, Marchhart has been using a Salvagnini P2.G4 panel bender, achieving not only the advantages of panel bending that had not yet been implemented, but also producing significantly more complex part geometries.

Flexible panel bender for maximum production efficiency

Highlights

- Marchhart

Originally established in 1968 by Johann Marchhart as a classic locksmith’s and blacksmith's workshop, Marchhart GmbH has evolved into a leading specialist in the production of components for office furniture and modular laboratory furniture systems. Their HVAC products range from individual components up to complex, complete air filter solutions, for example for hospitals, the pharmaceutical industry or laboratories. - The context

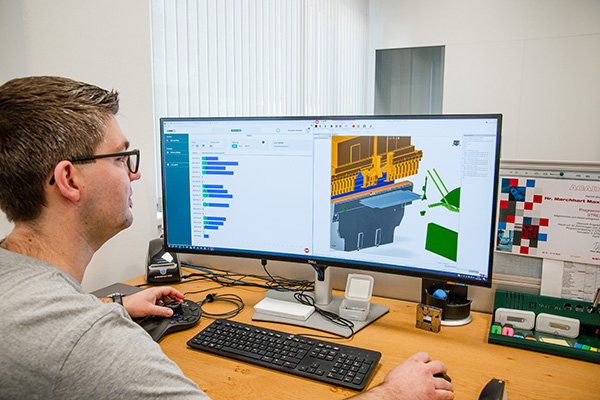

The family business from Burgenland was already well equipped for bending, with a conventional press brake as well as a fully-automated bending cell. However increasing product variants, increasingly complex geometries and the growing demand for small batch sizes required an additional, very flexible bending solution. “Salvagnini provided us with optimal support for this decision-making process and offered us a complete package that was perfectly tailored to our needs”, explains Clemens Marchhart, responsible for product development at Marchhart GmbH. - The project

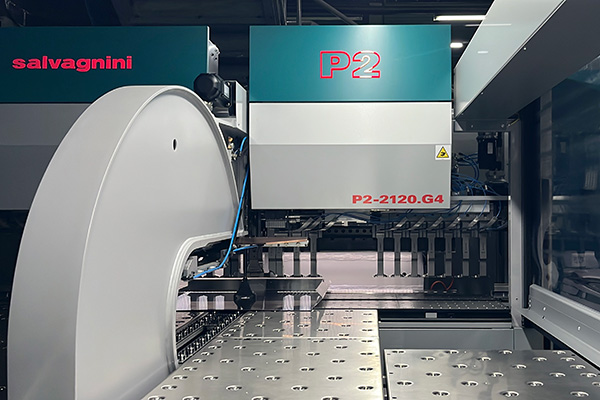

The specific choice was the P2-2120.G4 panel bender, producing parts with sheet thicknesses ranging from 0.4 to 3.2 mm, a maximum bending length of 2,180 mm, and a maximum bending height of 203 mm. The elimination of the tool setup times was a key factor in choosing the technology. Especially in light of the large number of orders with small batch sizes and a high range of variety that Marchhart produces according to customer requirements, this means considerable time savings and major benefits in terms of production efficiency. “In the case of many workpieces, we achieve up to four times the output using the new panel bender”, emphasizes Maximilian Marchhart, Manager of the Sheet Metal Center at Marchhart GmbH. Moreover, the Salvagnini panel bending solutions have an advantage in cases where optics are especially important: “The high quality of the P2.G4, which works without any marks, cannot be achieved with press brakes”. - The outcome

By starting with panel bending, Marchhart was able to increase production efficiency, expand its machining range, open up new market potential and further increase its competitiveness. “With Salvagnini’s P2.G4, we now have almost limitless bending possibilities and can therefore fulfill the continuously increasing customer requirements with the highest quality and maximum flexibility”, summarizes Maximilian Marchhart happily.

Check out the case study

Hear what Clemens Marchhart, responsible for product development at Marchhart GmbH, says about this project.