Case study

Maximum efficiency in batch size 1

Story and pictures courtesy of N. Novotny/Blechtechnik

Meiller is world-renowned as a top manufacturer of elevator doors and consistently relies on state-of-the-art manufacturing technologies. With the commissioning of another Salvagnini S4+P4 production line, the Munich-based company has once again placed its trust – for the third time – in the expertise of the Italian machine manufacturer. For Meiller, this investment is far more than the purchase of a new system: it represents a strategic step to make its production even more flexible and efficient, ensuring it is fully prepared for future demands.

Maximum efficiency in batch size 1

Highlights

- Meiller

Meiller Aufzugtüren GmbH, based in Munich, is a global premium manufacturer of automatic elevator doors. With 200 employees producing 30,000 doors annually for airports, hospitals, and high-rise buildings, Meiller combines over 170 years of manufacturing experience with state-of-the-art sheet metal technology. - The challenge

Traditional workshop production with multiple standalone machines created long throughput times, up to five days, high material handling, and limited flexibility. To sustain competitiveness, Meiller needed agile, fully connected production capable of handling custom parts down to batch size one while maintaining top precision and quality. - The solution

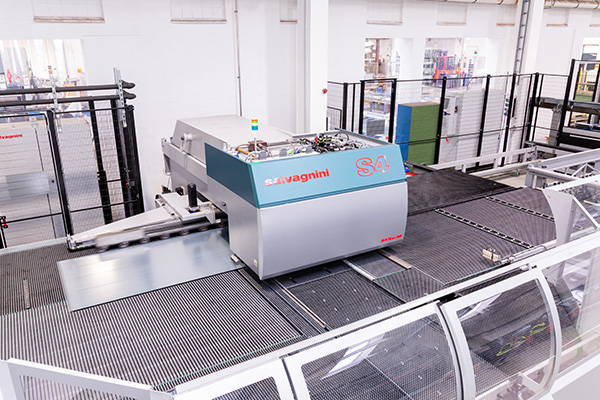

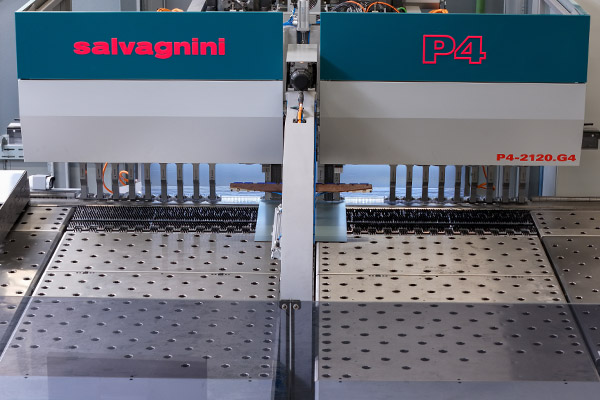

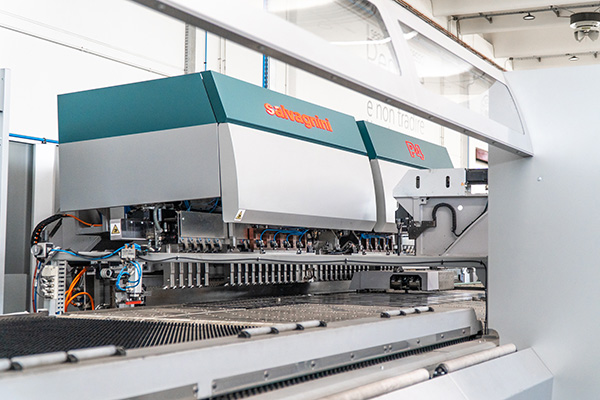

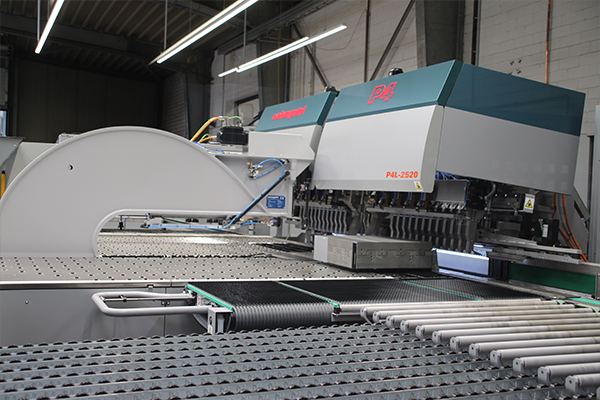

Meiller’s third Salvagnini investment, a new S4+P4 Flexible Smart Line, integrates an MD store-tower, S4 punching-shearing machine, MCU manipulator, and P4-3220 panel bender. The line operates with OPS production management software and STREAM for automatic programming, ensuring a seamless, fully automated process from raw sheet to finished component. - The results

Throughput time was reduced from five days to one. The system eliminates manual handling and tool changes, boosts flexibility for 5,000 part variants, and enhances repeatability and quality. “We produce to order starting from batch one. The fact that we can switch so quickly and efficiently between different parts makes all the difference,” says Michael Winkler, Production Manager at Meiller.

Check out the case study

Hear what Klaus Schafranietz, Chief Operating Officer, and Michael Winkler, Production Manager at Meiller, say about this project.