Case study

Industrial Laborum: the advantages that stem from flexibility

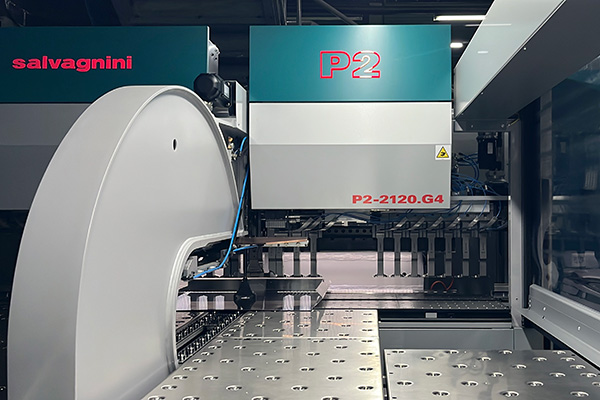

Industrial Laborum Ibérica was set up in 1978 to design, manufacture and install technical laboratory furnishings. Over the years, this Portuguese company, owned by the Lapa family, has extended its activities into other market segments – hospital and school furniture – and has developed commercial relations abroad. In 2020, to continue to compete in an increasingly demanding market, Industrial Laborum renewed its production layout, installing two Salvagnini machines: a P2 panel bender and a B3 press brake.

The advantages that stem from flexibility

Highlights

- Industrial Laborum

Industrial Laborum Ibérica was set up in 1978 to design, manufacture and install technical laboratory furnishings. Over the years, this Portuguese company, owned by the Lapa family, has extended its activities into other market segments – hospital and school furniture – and has developed commercial relations abroad. - The context

Managing a broad, differentiated market, with demands running from batch one to mass production, in 2017 the company from Albergaria-a-Velha launched a project to renew its production layout, in order to achieve greater flexibility. - The project

Considering its complex needs, Industrial Laborum chose two Salvagnini machines: a B3 press brake – a 3-meter, 135 ton model – and a P2-2116 panel bender. These two stand-alone systems communicate with each other via the proprietary processing software, and ensure maximum bending capacity as they combine the productivity of the panel bender with the versatility of the press brake. - The outcome

“In just over 6 months we have become 100% operational,” Paulo Correia, Sales Director of Industrial Laborum, explains. “The P2 was a particularly important investment for us. Today it helps us to be increasingly flexible, producing quickly with consistently high quality: we can produce 1 part or 1000, without any problems, with a really quick lead time. In the past, for a 30-part batch of metal furniture, we estimated a delivery time of 2 weeks. Today we produce the same batch in just 2 or 3 days. Another great result is that we have practically eliminated all work in progress: our workflow is very lean, on the same day we cut, complete the bending and send all the parts for welding. We have regained around 30% of our efficiency today by reducing secondary activities. We have better control over every step in the process.”