Case study

M.Köb: tripling production capacity, with the minimum footprint

Story courtesy of N. Novotny/Blechtechnik

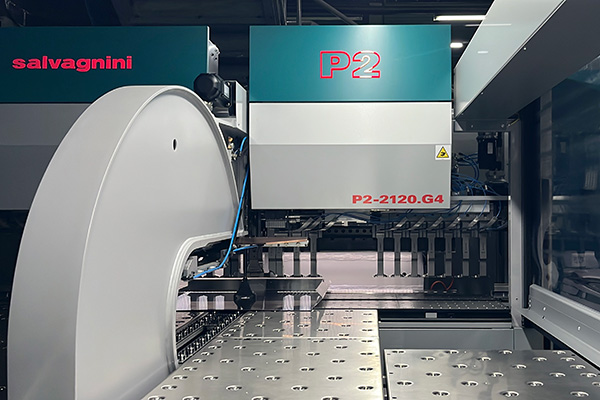

M.Köb is specialized in the construction of houses, plants, facades, and also a subcontractor in the sheet metal working and powder coating for the machinery industry. Thanks to the Salvagnini P2 panel bender, the company has enhanced the capacity to process larger orders in less time, and to considerably speed up the whole production process.

Tripling production capacity, with the minimum footprint

Highlights

- M.Köb

Founded in 1990, M.Köb is a family-run company mainly specialized in the construction of houses, plants, facades, but is also a subcontractor in the sheet metal working and powder coating for the machinery industry. With over 30 years of experience, the Austrian company can offer everything to its customers: from design to final products. - The context

Over the years, M.Köb continued to invest in new machinery, technology and personnel, which has enabled it to gradually increase the production capacity. One of the most significant turning points in M.Köb's history occurred in 2014, with the decision to expand the production area with a 1000 m² facility, dedicated exclusively to powder coating. Thanks to this, the company was finally able to manufacture in-house the entire product portfolio. "By renewing and expanding our machines, we create new production capacities and application possibilities quickly and efficiently – with the highest quality," explains Manfred Köb, the Managing Director. "Today we employ 16 people and, with material consumption of 180 tons, we boost 2.5 million € turnover". - The project

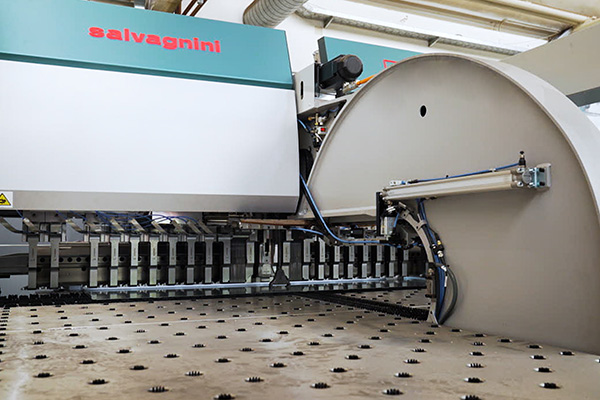

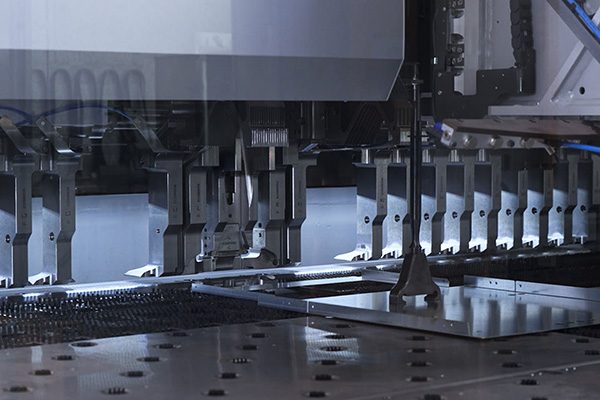

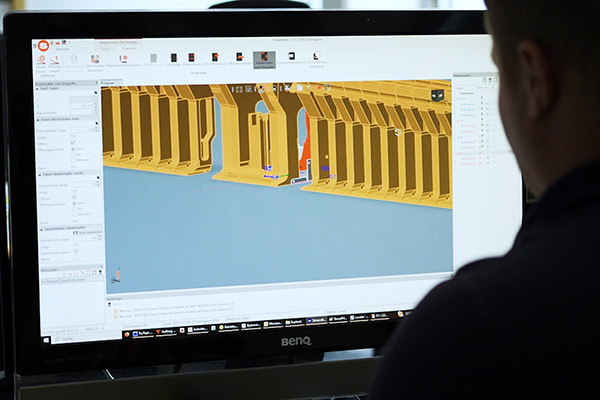

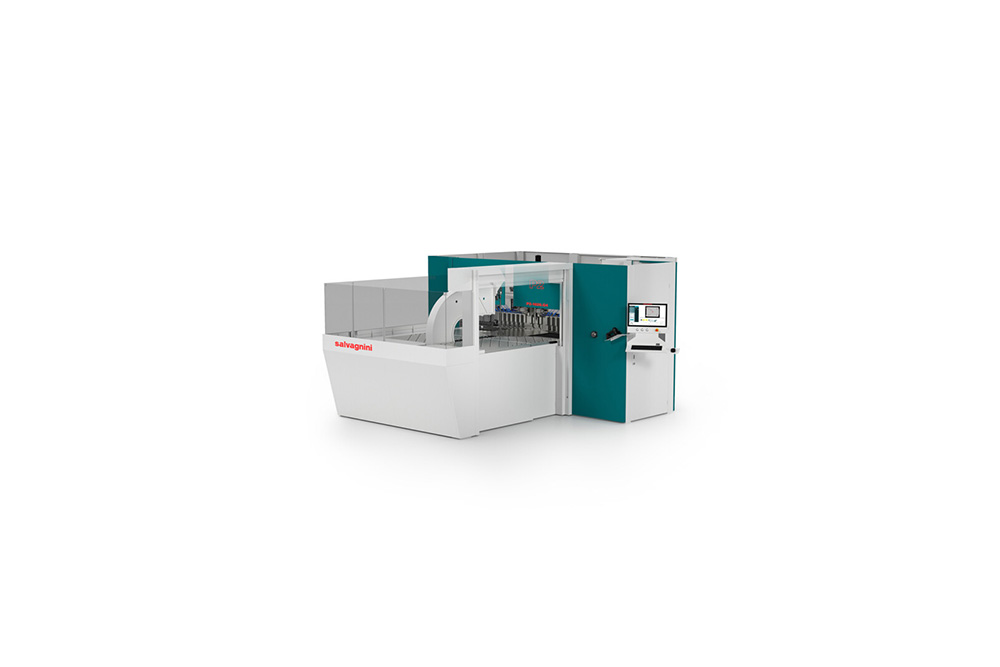

Before choosing the Salvagnini P2 panel bender, M.Köb's production was run with four press brakes. "The model we have chosen, a P2 2120, is about the same footprint as our old press brake, but it has allowed to triple our production capacity," explains Jakob Köb, the General Manager. "With the Salvagnini P2 panel bender, we meet our increasing demand and also enhance our efficiency. We benefit from a higher production speed and we do not waste time with tool changes. This makes our production definitely faster and more flexible," confirms Jakob Köb. - The outcome

"The panel bender will enable us to open new markets in the future, add new products to our range and manufacture flexibly," says Jakob Köb. "We want to take advantage of these innovations as a pioneer and set market trends. We expect the investment to increase our turnover by up to 15%. At the same time, modern machines make it possible to physically relieve our staff and create new jobs," adds Manfred Köb.

Check out the case study

Hear what Jakob Köb, General Manager of M.Köb, says about this project.